Zero-emission technologies part of John Deere stand

12 November 2025

Company shows latest developments in alternative drive technologies at Agritechnica.

During Agritechnica 2025 in Hanover, Germany, a portion of John Deere’s massive stand was dedicated to its latest developments in alternative drive technologies, reflecting the company’s commitment to sustainable powertrain solutions across all agricultural segments.

Multi-Path Strategy

John Deere is pursuing a multi-path strategy that includes the continued advancement of internal combustion engines, the integration of renewable fuels and the development of electrified powertrains.

The company said this diversified approach ensures that customers can select the most suitable solution for their operational needs, while also aligning with evolving environmental standards and energy policies. Biofuels The use of biofuels such as ethanol, biodiesel and renewable diesel offers a significant reduction in CO₂ emissions on a well-to-wheel basis.

John Deere is actively researching and implementing advanced combustion technologies to ensure compatibility and performance with these fuels. Biodiesel remains a key component of this strategy. John Deere Stage V engines, compliant with EU regulations, support biodiesel blends up to 8% (B8). Final Tier 4/Stage IV and Interim Tier 4/Stage III B engines are approved for blends up to 30% (B30), while Tier 3/Stage III A and lower tier engines can operate on 100% biodiesel (B100).

Renewable diesel, including hydrotreated vegetable oil (HVO), is another viable option. As a paraffinic diesel fuel, it can be used either as a blend or at full concentration (RD100) without requiring engine modifications. John Deere engines are compatible with renewable diesel fuels that meet ASTM D975, EN 590, or EN 15940 specifications. This fuel type offers high energy content and low carbon intensity, making it particularly relevant for European markets focused on decarbonization.

The John Deere E-Power tractor prototype was designed for specialized applications. (Photo: Chad Elmore)

The John Deere E-Power tractor prototype was designed for specialized applications. (Photo: Chad Elmore)

Electrification

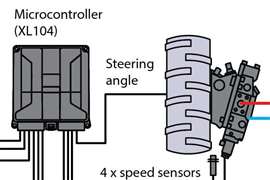

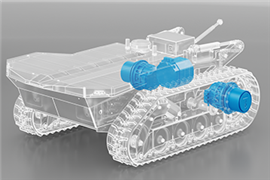

Electrification is another pillar of John Deere’s alternative drive portfolio. Battery requirements vary significantly by application, and John Deere is leveraging the expertise of Kreisel Electric to develop modular, high-performance battery systems. These systems are engineered for high energy density, extended runtime, and seamless integration into agricultural machinery. The flexible architecture of Kreisel batteries enables scalable solutions across different machine platforms. The batteries have a patented cell immersion cooling technology and advanced software systems.

During the show, the company displayed the E-Power tractor prototype, designed for specialized applications such as orchards, vineyards, municipal services and livestock operations.

The fully battery electric machine features a completely new, uniform base design with configurable options for battery capacity, cab type, axle configuration and tyres. The E-Power prototype tractor delivers 130 continuous horsepower and is capable of performing the same tasks as a conventional diesel utility tractor. It operates with zero emissions and supports up to five Kreisel batteries, allowing users to tailor runtime and power output to their specific requirements. The tractor is compatible with existing implements and offers operational advantages including instant torque, reduced noise, lower maintenance demands, and a simplified driving experience, said the company.

Integration with the John Deere Operations Center enables remote diagnostics, runtime monitoring, charging management and data-driven insights. John Deere’s alternative drive strategy is engineered to support the transition toward low-emission agriculture while targeting diesel-like performance and reliability. By offering a range of technically validated solutions, the company is supporting European farmers and contractors meet both operational and regulatory demands in a rapidly changing energy landscape.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM