Read this article in 中文 Français Deutsch Italiano Português Español

Turntide shares 5 reasons to choose axial flux motors

18 March 2025

When selecting a motor for battery-electric or hybrid vehicles or equipment, engineers must select one that provides the torque and power needed, functions well within the system and fits in the available space in the vehicle or equipment. When working with weight-sensitive applications, the motor must also not be too heavy.

In many cases, engineers and designers must choose between a radial flux motor and an axial flux motor. Following are five reasons why an axial flux motor can be the preferred solution for the application.

Image 1. Radial Flux motor (Source: Turntide)

Image 1. Radial Flux motor (Source: Turntide)

1. Ideal Size for Small Footprints

In many electric or hybrid systems, especially in retrofits of traditional internal combustion engines, space is at a premium. Radial flux motors are the motors that often come to mind.

Radial flux motors are used in many applications, including electric and hybrid vehicles (see Image 1). These motors have a long body and are heavier than axial flux motors.

One reason that axial flux motors (see Image 2) are an ideal choice is that they are flatter than radial motors and weigh less. They are often called pancake motors. They provide engineers and designers with more room for the battery, inverter or controller, and thermal solutions — all required in an electric or hybrid system. Axial flux motors are stackable, compact electric motors designed for high power and torque density.

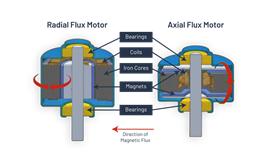

Image 2. An axial flux motor (Source: Turntide)

Image 2. An axial flux motor (Source: Turntide)

In addition, the windings of a radial flux motor are perpendicular to the magnets. In axial flux motors, the magnets are in planes parallel to the windings. This difference in the magnets and coils impacts the torque, power and efficiency of the motors.

2. Higher Power, Torque and Efficiency

While axial flux motors are lighter and require less space, their torque, power and efficiency are higher than a radial flux motor. How is this possible?

A key determinant of torque and power delivery and, therefore, efficiency is the magnetic field strength. Magnetic field strength is higher if the magnetic flux path is shorter.

Therefore, field strength increases with the diameter (D) of the rotor containing the magnetic material and reduces with the length (L) of the flux path (see Image 3). A higher D/L ratio provides a motor with a higher efficiency and a higher torque density.

Axial flux motors have a higher D/L ratio than radial flux motors. This gives them higher torque and power.

Image 3. Motor magnetic flux (Source: Turntide)

Image 3. Motor magnetic flux (Source: Turntide)

Axial flux motors, depending on their size, are two to four times more torque dense than the standard radial flux motor. This torque improvement results in a 50% weight and volume savings for the powertrain.

In addition, for a radial flux motor, the torque is proportional to the square of the diameter multiplied by the length (see Image 4). For an axial flux motor, the torque is proportional to the cube of the diameter, and it has no significant influence on the length.

These factors detail the reason that axial flux motors have more torque than a radial flux motor. This torque, less weight and the flatter profile make them ideal for hybrid configurations or the fully electric system of any vehicle or equipment, especially if space is limited.

3. Flexibility

Axial flux motors streamline the path to electrification, allowing for rapid integration and scalability. Purpose built for original equipment manufacturers (OEMs), these motors accelerate their time to market while providing quality and durability.

Whether producing in high volumes or scaling up, their modular, stackable designs allow for fast product adaptation and pairing with inverters and motor controllers.

4. Cost Effective

An axial flux motor can reduce an electric system’s weight by 50%. In addition, a 10% reduction in vehicle weight can improve the vehicle’s range by 13.7%. This leads to a cycle of powertrain and vehicle weight reduction and higher vehicle range that results in lower total cost of ownership (TCO).

Image 4. Axial Flux Motor Torque (Source: Turntide)

Image 4. Axial Flux Motor Torque (Source: Turntide)

Also, the high-torque and low-speed operation suitability of an axial flux motor eliminates the gearing ratio. This further reduces the vehicle weight and simplifies the powertrain complexity.

Producing these motors at economies of scale will be a deciding factor in their cost effectiveness, which will decrease the initial purchase price. Some axial flux motors are designed for seamless integration into industrial equipment and are priced to enhance profitability.

5. Quick Delivery

Because of scaled production, some axial flux motors can be delivered faster than in the past. Before recent process improvements, axial flux motors were typically used in niche applications in which the delivery time was not a huge issue. With the new production capacity, waiting for delivery of some motors is no longer the norm.

So, why should engineers and designers of hybrid and electric vehicles and equipment select an axial flux motor? To ensure an efficient, cost-effective powerful system with less weight, a low TCO and a small footprint.

Matrishvan Raval is product head for Turntide Technologies.

Applications for Axial Flux Motors

Axial flux motors are a fit for many systems. However, they are an especially suitable choice for hybrid and electric vehicles and equipment, where weight limits are present and space under the hood is constrained. This includes:

On-highway

- Traction (including e-axle Integration)

- e-power take-off

- Ancillary applications such as cooling pumps and fans for battery-electric and hybrid configuration vehicles

- Fuel cell superchargers

Off-highway

- Construction and mining equipment — wheel traction, track traction and ancillary functions (such as slew and swing)

- Agriculture equipment — wheel traction, track traction and ancillary functions

- Street sweepers — traction and implements

- All-terrain vehicles — traction

Premium automotive

- Traction for premium automotive cars and high-performance e-motorbikes

Marine

- Offboard motors and marine e-propellers

- Auxiliary power on hybrid boats — sailing, pleasure and fishing boats

- Winches and cranes on ships

Rail

- Traction for trams and light railway

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM