Bauma Exclusive: Hatz builds on engines and electrification

12 May 2025

Hatz unveiled its F-Series engine family at Bauma 2025. (Photo: Becky Schultz)

Hatz unveiled its F-Series engine family at Bauma 2025. (Photo: Becky Schultz)

Motorenfabrik Hatz (Hatz) announced a “world premiere” at Bauma 2025 in Munich, Germany, with the unveiling of its new F-Series engine family. The new engines fill a gap in the company’s product portfolio by adding displacements from 0.95 to 1.75 L.

“There was something missing in our portfolio still for superior diesel engines,” said Bernhard Richter-Schützeneder, director Sales & Service Global, Hatz, at the unveiling. “The new series of engines is positioned between our existing 1B-Series and D-Series which go up to 11 kW and the H Series that start at 18.4 kW.”

Though just three of the new models were on display, the F-Series encompasses four engines for mobile machines and six targeted for generator applications, with EPA Tier 4 Final and EU Stage V variants available. Power ratings range from 7.5 to 18.4 kW (10.1 to 24.7 hp).

The F-Series completes the engine range for both Hatz and its customers.

“Many times, we didn’t have something to offer under 25 hp. So, [customers] might be using Hatz’s bigger engines, but on the small side, they’d have to use something else,” said Michael Hartoonian, president and CEO, Hatz North America, who was on hand for the unveiling. “Now we get to complete that range for everybody and keep people 100% Hatz.”

The new engines are currently available for sale with most already in stock.

Internally designed, built and serviced

The smallest model in the F-Series is the 3F30 at just under 1 L displacement. The three-cylinder engine provides 15.8 kW (21.2 hp) at 3,000 rpm or 7.5 kW at 1,500 rpm for 50-Hz generators.

The 3F35E is made from the same engine block but offers 150cc more displacement at 1.1 L. “Thanks to the electronic speed control, it’s compliant to EPA Tier 4 Final and EU Stage V and it develops 18.4 kW at 3,000 rpm and only 110 kg of weight,” said Richter-Schützeneder. “This engine is built as a complete open power unit… a robust design, heavy-duty power pack which has been completely designed and built by Hatz and is completely serviced by Hatz.

Hatz 3F35E open power unit diesel engine. (Photo: Becky Schultz)

Hatz 3F35E open power unit diesel engine. (Photo: Becky Schultz)

“That’s a significant advantage for machine builders and users,” he continued. “And the electronics, the cooling circuit, the air circuit and the complete exhaust system are made by the engine manufacturer with international warranty and service.”

The third engine displayed on the stand was the 3F45E, also shown as a complete open power unit. The three-cylinder, Tier 4 Final-compliant engine has a 1.3 L displacement with electronic speed control and is rated 18.4 kW at 2,500 rpm for Tier 4 Final. Its “sister” engine, the 3F45, is rated 18.4 kW for EU Stage V with a mechanical governor.

“As a generator engine, the power output of the 3F45E is 14.2 kW (19 hp) at 1,800 rpm and the 3F45, the mechanical version, provides 11 kW (14.8 hp) at 1,500 rpm,” Richter-Schützeneder noted.

Two additional models in the family not shown at Bauma were the 4F45 and the 4F45E four-cylinder engines with 1.7 L displacement. “These models are totally dedicated to generator purposes, so they are only available as fixed speed operation and they provide 16 kW (21.5 hp) at 1,500 rpm and 18.4 kW at 1,800 rpm,” said Richter-Schützeneder.

Drop-in solution

Development of the new engine series was the result of a collaboration between the different branches of Hatz.

“The American engineering team developed a solution and the German team developed a solution, and then we brought the best things together into production,” Richter-Schützeneder explained. “If you bring both sides together, you can make a solution that fits for both markets.”

Development of the F-Series was the result of a collaboration between the different branches of Hatz. (Photo: Becky Schultz)

Development of the F-Series was the result of a collaboration between the different branches of Hatz. (Photo: Becky Schultz)

Other branches of the company, such as Hatz Netherland, were also involved in the F-Series’ development. “It was a joint approach,” said Richter-Schützeneder.

Because there are already numerous engine options available in this size class, Hatz chose to focus on “re-motorization projects” with the F-Series.

“Every time we can sell an engine, we have to replace a competitor. And how do you do that with the most compact size, because if it doesn’t fit in a machine, it doesn’t fit in a machine,” Richter- Schützeneder commented.

So, Hatz’s engineering team identified a size limit for the new engines to ensure they could fit within a specified footprint for minimal modification to existing machines. “What we wanted to have, and what the market wanted to have, is a drop-in solution for the customer segments that we are addressing now,” said Richter-Schützeneder.

Also essential was keeping things simple. “Innovation is our tradition. That’s what our motto is,” Richter-Schützeneder stated. “But at the end of the day, the customer is always right. And in this power class, the customer wants quiet engines at a low price… If they want a big machine with high performance, they come to us for the H50 product line, and then they are willing to pay for extra.

“Of course, we will offer [on the F-Series] all the additional features that we have, like IoT and things like that, but being a mechanical product, the benefit of it is not what it is on bigger power classes.”

Next-gen Concept Cube

Hatz’s tradition of innovation did prove central to the development of the eDrives featured in the Bauma stand. They were presented in the form of the Concept Cube 2.0 demonstration machine.

Hatz Concept Cube 2.0 demonstrator machine. (Photo: Becky Schultz)

Hatz Concept Cube 2.0 demonstrator machine. (Photo: Becky Schultz)

The first iteration of the Concept Cube, shown at Bauma 2022, represented Hatz’s vision for the future of vibratory soil compaction. The latest iteration brings that vision to life, with a full-size working model demoed in an outdoor exhibit area at the 2025 event.

“We have been working on electric drives for three to four years. We analyzed the strengths and weaknesses and designed the drivetrain with this knowledge,” said Dr. Sebastian Wohlgemuth, the recently appointed CEO of Hatz Components GmbH, who previously served as director of Research & Development for Motorenfabrik Hatz. “We analyzed the technology on the one side, but on the other side, we had a close look at the machine itself to understand the compaction business. And we analyzed the customer needs.

“We brought it all together in the Hatz eDrive system and what you can see here at the booth are the real components, which will be our scope of delivery in the future,” Wohlgemuth said at the machine’s unveiling. “This system will be the future of soil compaction.”

Two versions of eDrives were displayed: one with two motors for forward and backward movement similar to a traditional reversible plate compactor; and one with four motors that add sideways movement and turning capability. “The imbalances (eccentric weights) are directly mounted on each motor, meaning no losses and high efficiency”, said Wohlgemuth.

A perfect fit

The upper part of the Concept Cube 2.0 houses the inverters and the control unit, which are utilized to electronically synchronize the motors.

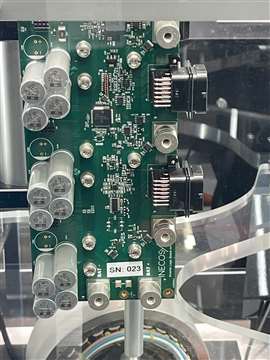

Inecosys supplied the necessary experience in electronics development, calibration and software solutions for the Concept Cube 2.0 project. (Photo: Becky Schultz)

Inecosys supplied the necessary experience in electronics development, calibration and software solutions for the Concept Cube 2.0 project. (Photo: Becky Schultz)

“That’s also part of [Hatz’s] scope of delivery,” Wohlgemuth said. “We developed our own inverters and control unit… because the available inverters and control units are not programmable in such a deep layer that you can fast and precisely control the position of the imbalances.”

Fortunately, Inecosys, a provider of customized hardware and software solutions based in Munich, joined the Hatz family in 2021. Its product experts supplied the necessary experience in electronics development, calibration and software solutions.

“We had the opportunity to enlarge the R&D department of Hatz with these people with a different knowledge. It’s a perfect fit,” said Wohlgemuth. “And we also now expanded the business of Inecosys in April with a new CEO and more topics.

“It’s new technology for Hatz,” he acknowledged. “It’s nice that we have the opportunity for Hatz Components to be part of that by machining some parts for the drive concept. In the global picture, that shows all the knowledge and capabilities that we have in the Hatz Group.

“That’s also good for our customers, because they’re not just buying a single part. We also have the expertise in the background to support our customers.”

Beyond compaction

In addition to what was shown by Hatz, Japanese manufacturer Mikasa and Sweden-based Swepac showed vibratory compactor models at Bauma equipped with Hatz eDrives. The OEM customers will be among the partners aiding in further product development prior to field testing with end users to obtain their feedback.

The aim is to have eDrives in series production by the time the next Bauma rolls around in 2028. Once this is achieved, the company anticipates moving beyond compaction to other machine forms.

“We started with the compaction business as we know the business very well and it has an important market share for us,” said Wohlgemuth. “It’s a very rough business and with the huge forces on the machine and the parts, it’s very challenging.

“When we show that we are capable of controlling the motors and creating a robust system under these conditions, we can do [that for] every machine,” he continued. “So, it’s a hard application as a starter, but it fits perfect to Hatz.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM