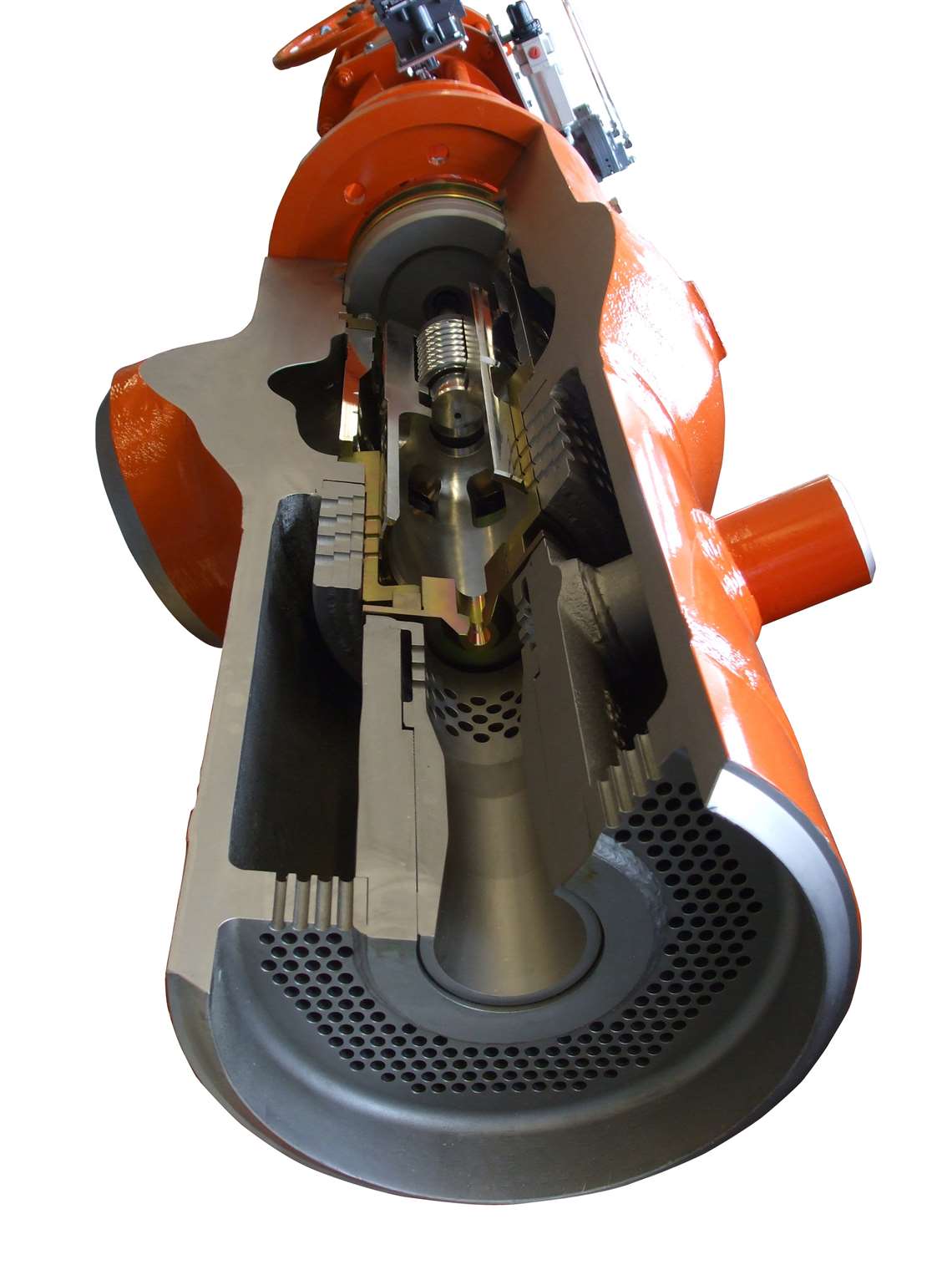

Copes Vulcan DSCV-SA steam conditioning valve

22 February 2021

Specifically designed for arduous applications such as steam turbine bypass systems, continuous steam letdown stations and CHP plants, Copes Vulcan said its Direct Steam Converting Valve-Steam Atomization (DSCV-SA) is particularly suited to isolation of the steam flow in turbine bypass applications where valves remain closed for long periods of time, the company said.

The DSCV-SA is designed to minimize potential risks associated with plant start-up, shutdown and turbine trips, the company said. The valve features a pilot plug design that achieves a very tight shut-off in the closed position, using the full steam pressure to seal the plug. This load, combined with the actuator thrust, results in very high seat contact loads. This tight seal improves plant thermal efficiency, and also prevents leak-induced ‘wire drawing’ damage across the valve seat which would otherwise result in frequent maintenance to repair or replace the seat.

The DSCV-SA’s use of steam atomization for cooling water introduction also has several major benefits. The atomizing steam

The Copes Vulcan DSCV-SA from Celeros Flow Technology is specifically designed for arduous applications such as steam turbine bypass systems, continuous steam letdown stations and CHP plants.

The Copes Vulcan DSCV-SA from Celeros Flow Technology is specifically designed for arduous applications such as steam turbine bypass systems, continuous steam letdown stations and CHP plants.

pre-heats the cooling water, accelerating the evaporation and desuperheating process. Very fine atomization of the incoming cooling water produces a massively increased surface area to promote rapid heat transfer. The atomized, pre-heated water is introduced into the center of the steam flow, while the finely atomized cooling water is carried by the atomizing steam itself, and therefore has no dependency on the main steam velocity. This makes the DSCV-SA unrivaled for rangeability (turndown).

High pressure (P1) balancing is another key design feature and delivers reliable, smooth operation by eliminating the need for auxiliary seals used in low pressure (P2) balancing, which can wear or become damaged and lead to the valve oscillating violently or even failing to open on command. The DSCV-SA requires very little maintenance once installed, the company said. Should in-situ maintenance be necessary, the complete trim is a ‘Quick-Change’ style with no welded-in components or large internal threaded parts, so it simply slides out of the top of the valve. There is no need for any specialized tooling or training.

The DSCV-SA is available in an almost infinite range of sizes as each valve is tailored to suit individual customer’s application requirements. The valve can be fully or split rated design and is available in standard, special or intermediate class. The DSCV-SA also comes equipped with modern ‘SMART’ instrumentation to suit all forms of communication protocol, fail-safe requirements, responsiveness and accuracy.

Copes Vulcan is a brand of Celeros Flow Technology.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM