Cummins To Debut Engine

31 January 2019

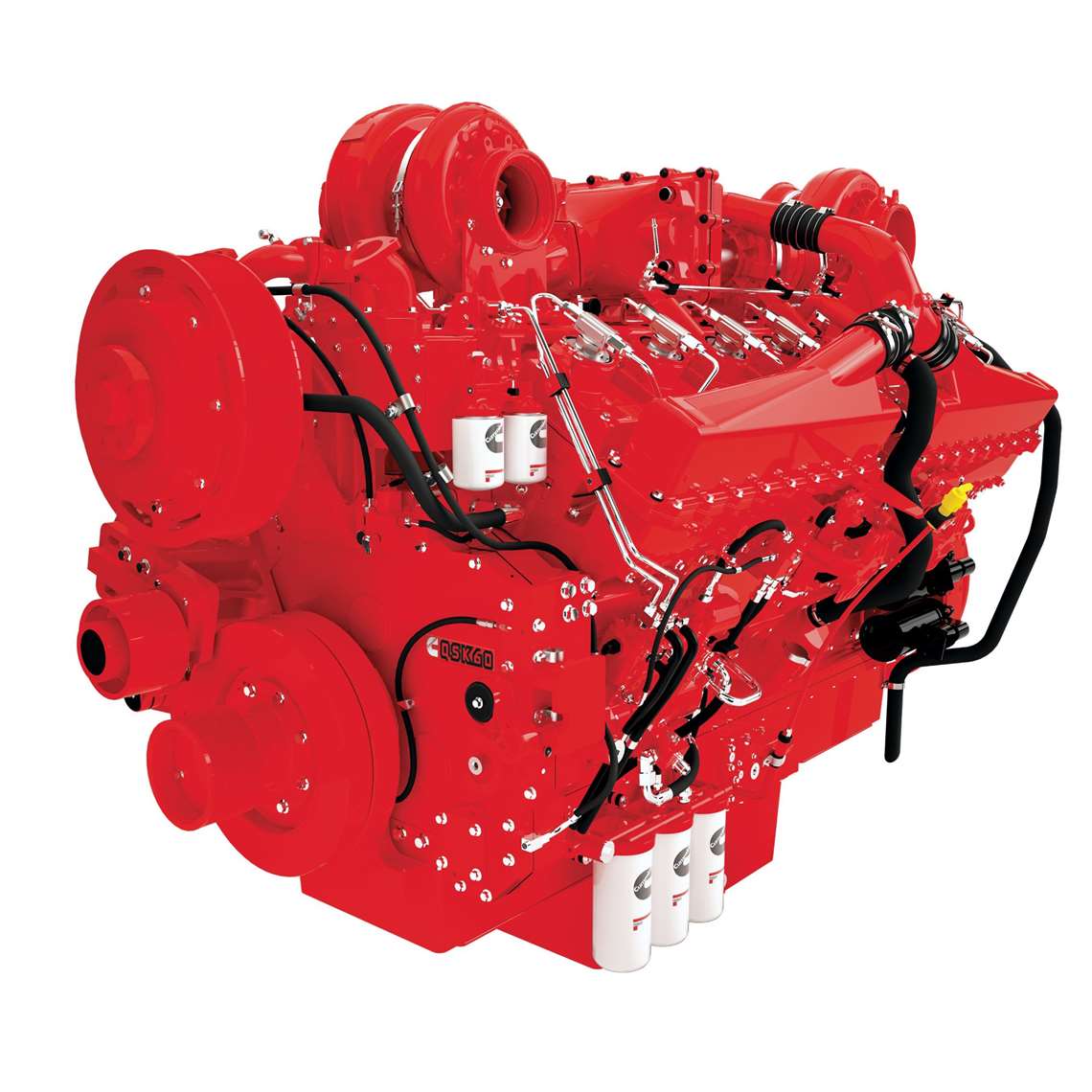

At the Bauma trade show in Munich, Germany, Cummins said it will debut the QSK60 Stage 5 engine which is part of its 560-2611 kW (750-3500 hp) mining line up.

The QSK60 is available from 1398-2125 kW (1875-2850 hp) for excavator and dump truck use with a durability of approximately 4.2 million litres (1.1 million US gallons to overhaul).

Cummins said its Stage 5 products come with more power and torque, are less complex and easier to install, and require less servicing. This offers OEMs the ability to increase machine capability and offer more value or downsize engines to reduce cost, the company added. The B6.7 to be displayed at Bauma offers 30% higher torque than Stage 4 with 243 kW (326 hp) of power, enabling it to replace an engine of higher displacement with no impact on machine operation, said Cummins.

Also featured at Bauma will be the Stage 5 F3.8 power unit. Delivered as a complete and ready-made power package, it comprises an engine, Single Module aftertreatment, radiator and cooling system – as well as auxiliaries such as mounting feet, hoses and an air cleaner.

The unit is more than 70% pre-approved for installation, said Cummins. Stage 5 engines and power units are available from 75–503 kW (100–675 hp).

A redesigned power cylinder, optimised wastegate turbocharging and improved crankcase breather system work to keep particulate matter (PM) below the Stage 5 levels. Cummins modular SCR system is used to reduce NOx to the required level and features an integrated decomposition chamber and Cummins’ airless dosing system designed to last the life of the engine.

The use of SCR reduces engine back pressure, for increased fuel economy and optimised temperature management minimises Adblue/DEF consumption, the company added.

The two-stage QSK60 engine features a simplified air handling configuration using Cummins turbochargers with intercoolers to achieve an altitude capability of over 3,500 m with easy access to the top end for servicing, said Cummins.

The latest NanoNet filtration technology captures and retains more harmful particles than traditional media, for longer fuel pump and injector life with better reliability, according to Cummins.

Alexei Ustinov, vice president Off-Highway Engine Business said: “Since unveiling our Stage 5 construction engines at Bauma 2016, we have made great progress and are in production with all engine models from F3.8 to X15. We have over 200 machine installations completed or in progress, which is more than at Stage 4, and our customers benefitting from key product updates that deliver more with less. We are developing alternate power capability such as hybrid, electric and fuel cells, however Stage 5 remains a key part of our plan.”

Cummins also announced the availability of fixed speed G-Drive Stage 5 engines for Bauma. The benefits seen with the variable speed Stage 5 engines of higher power density and reduced complexity (by the removal of EGR and using a simpler aftertreatment system) have been carried over, with further optimisation for generator set use, said Cummins

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM