Read this article in Français Deutsch Italiano Português Español

Dimethyl ether as a diesel fuel replacement

15 January 2024

While it has not been as broadly adopted as other replacements for diesel fuel, dimethyl ether (DME) has promise. Oberon Fuels, a producer and champion of DME, explains why.

Among the various alternative fuels and power sources available in the equipment market today, there remains a category known as “emerging fuels.” The Office of Energy Efficiency & Renewable Energy (EERE) of the U.S. Department of Energy says on its website that these fuels “may increase energy security, reduce emissions, improve vehicle performance and stimulate the U.S. economy.”

One such emerging fuel is dimethyl ether (DME), which while being chemically similar to liquid petroleum gas (LPG, or propane) has promise as a replacement for diesel fuel. DME is nontoxic and has a track record of safe usage in consumer products as an aerosol propellant.

California-based Oberon Fuels began producing renewable DME fuel in May 2021 at its Maverick plant located in Southern California’s Imperial Valley. Co-founder and Chief Technology Officer Elliot Anise-Hicks said DME has a number of qualities that make it an excellent replacement for diesel fuel.

Advantages Over Diesel

“It has a high cetane number, so you get very good performance out of it — and you don’t generate any particular matter,” he said. “Because of the structure of the molecule itself — it has an oxygen in the middle of two carbon/hydrogen groups on the sides — when it combusts, it doesn’t generate particulate matter. That allows the engine manufacturers to really reduce NOx output, and you’re able to take off the diesel particulate trap that you typically have on the on the engine because you’re just not generating that particulate matter.”

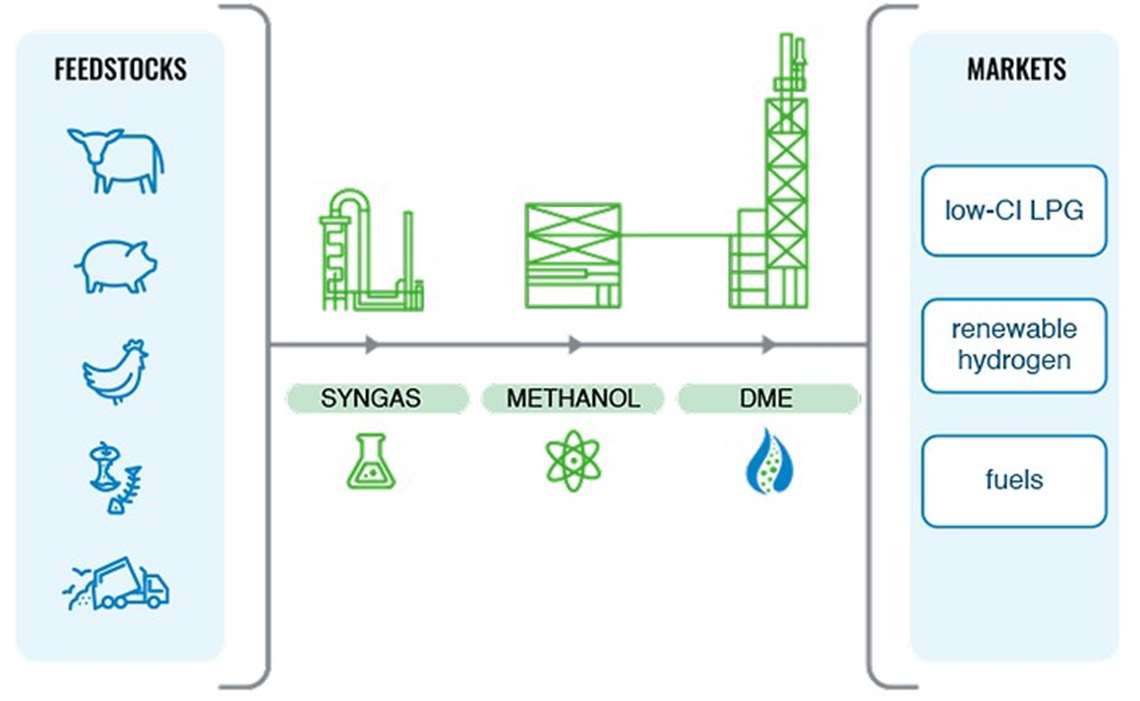

Oberon Fuels can use many different types of renewable organic wastes, including wastes from biomass, agriculture, municipal and cellulosic sources, to produce DME. (Image: Oberon Fuels)

Oberon Fuels can use many different types of renewable organic wastes, including wastes from biomass, agriculture, municipal and cellulosic sources, to produce DME. (Image: Oberon Fuels)

An additional benefit comes from DME’s handling characteristics, which Anise-Hicks said is “almost identical” to LPG.

“The main difference between DME and propane is that DME is an excellent solvent,” he said. “So when we look at storing and transporting DME, we can use all the same equipment that we use with propane except that we need to change the seals on the valves in order to make sure they’re compatible. That was one reason we spent a lot of time working on DME for diesel applications. The ease of handling certainly allows it to be distributed through the existing LPG infrastructure, and that makes it inexpensive and safe to handle.”

Fueling System Modifications

Once introduced to a diesel engine, Anise-Hicks said DME combusts very well, resulting in the same engine performance as if it was running on diesel. However, modifications must be made to an engine’s fueling system to handle DME.

“Your tank is a low-pressure tank — you’re storing [DME] at roughly 100 psi, much like propane,” he said. “It’s not a high-pressure tank like a CNG tank, but it is under mild pressure. Then volumetrically, DME is about half the energy content of diesel — a little over half. So volume-wise, you need to have a somewhat larger tank. Most importantly on the injectors, you need to have a larger port in order to get the same amount of fuel in.”

Anise-Hicks said that even with the modifications to the fuel delivery system, more than 90 percent of the engine remains the same compared to a traditional diesel engine. He added that while diesel engines can technically be retrofitted with new fuel delivery systems, there are issues with such an approach.

“The challenge with retrofit kits is that there’s a whole certification process that comes along with developing a kit and getting it to market,” he said. “Is it doable? Absolutely. Is there a sufficient market demand in order to justify the upfront costs of testing and getting certification with CARB for each engine family? Not yet.” Anise-Hicks added that this might change as DME fuel production expands and as DME becomes more accepted as a diesel replacement fuel.

Fostering DME Adoption

In the near term, bringing DME-ready diesel engines to the market will really be the responsibility of engine makers, and Anise-Hicks said that many engine makers are either considering DME or are actively developing DME projects.

“That’s actually not that far away, because among other things, Fiat Powertrain [FPT Industrial] has been developing a DME engine — a version of its Cursor 11 and 13 engines.” Power Progress reported in 2021 that FPT Industrial was testing DME as an alternative fuel source in its engines.

In the meantime, Oberon fuels is focusing on expanding DME production. “As we get more DME production in place, then hopefully we can encourage the other parts of the market to come along and deliver this as a solution,” Anise-Hicks said. “Because we do think, based on our experience and looking around, especially when you look at things like agriculture, mining and heavy construction — these are areas which are very difficult to electrify — DME is a really fantastic fuel, partly because of that no particulate matter. When you’re looking at mine operations, you can’t have heavy emissions in a mine, because you have very stringent air quality controls.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM