Electric Lonestar terminal tractor gets Link cab suspension

05 February 2021

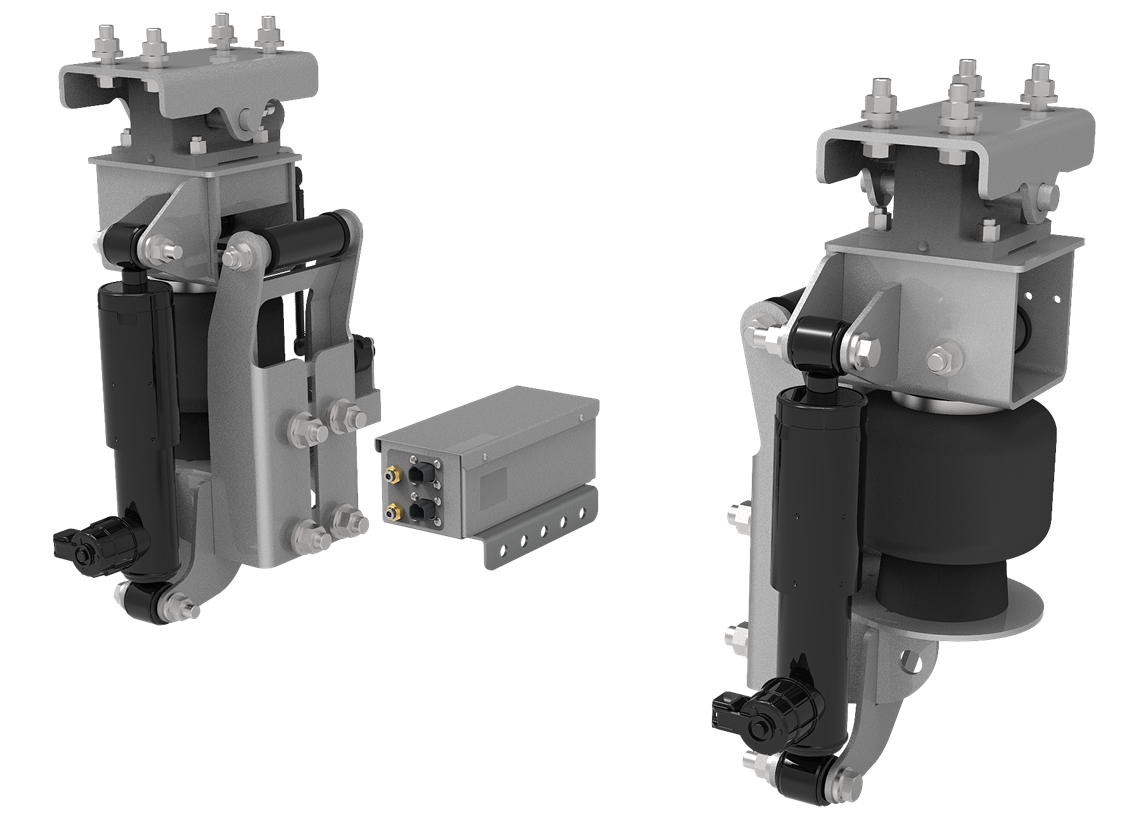

Link ROI Cabmate smart cab suspension to improve ride quality, stability and comfort for Lonestar EV terminal tractors.

Lonestar Specialty Vehicles has worked with Link Mfg. Ltd., a manufacturer of specialty-engineered suspensions, to outfit its electric terminal tractors with new ROI Cabmate smart cab suspensions.

Introduced in 2019, Link’s Road Optimized Innovation (ROI) technology enables a vehicle’s cab suspension to respond to external conditions in real time by continuously adjusting the stiffness of shock absorbers to optimize ride stability and comfort. The ROI Cabmate Smart Cab Suspension also features electronic height control that minimizes air consumption compared to traditional height control valves, because it does not fill or exhaust air in response to dynamic suspension motion.

“Terminal tractors are subjected to some of the harshest applications in the commercial vehicle space and operate on a wide variety of surfaces,” said Blake Yazel, general manager of Lonestar Specialty Vehicles, Texarkana, Texas. “Equipped with Link’s ROI Cabmate suspension, our electric terminal tractors are able to provide optimal ride stability and comfort, even when operating in the toughest applications. The engineering and quality construction of the ROI Cabmate compliments our advanced EV technology very well and we couldn’t be happier with its performance on our product.”

Terminal tractors must deal with a broad array of terrains while vehicles and drivers alike must cope with multiple drop and hook cycles per day. The concussive forces associated with repetitive coupling and decoupling of trailers alone can take their toll on man and machine.

Operators of terminal tractors may be exposed to dynamic forces that, according to ISO 2631-1:1997 standards, can cause internal injury over time. The ROI Cabmate can reduce the potential for injury and thus help reduce health risks while increasing worker satisfaction and productivity.

The ROI Cabmate suspensions on Lonestar SV’s electric terminal tractors employ multiple sensors that never stop monitoring or responding to the vehicle’s environmental circumstances. An accelerometer monitors the motion of the cab, while a position sensor measures the position and velocity of the cab relative to its frame.

“A terminal tractor using Link’s ROI Cabmate will operate in a constant state of dynamic damping, producing an optimal ride, improving operator alertness and reducing fatigue,” said Eli DeGroff, product manager, Road Optimized Innovations for Link Mfg., Sioux Center, Iowa. “Regardless of what a vehicle encounters in its working environment, the ROI Cabmate instantly responds with the ideal suspension stiffness to control and minimize cab motion and vibration.”

Driver retention continues to be a major factor for today’s fleets. The ROI Cabmate cab suspension improves the driving experience by increasing driver satisfaction, maximizing driver comfort and minimizing driver fatigue, said Link.

“No other industry supplier has done more to promote ride quality, stability and comfort for drivers, and nobody else has anything like Link’s ROI technology,” said DeGroff. “Our work with Lonestar and others is helping to set the table for a variety of new on- and off-highway applications.”

Lonestar Specialty Vehicles is a supplier of remanufactured commercial vehicles using glider kits and has more than 2800 Class 8 trucks and tractors commercially deployed. It introduced its first electric terminal tractor in late 2019.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM