Exacting Efficiency

16 January 2018

BY JACK BURKE

A little bit here, a little bit there.

That’s part of the strategy GE Power said it has employed to achieve 64% efficiency for its 9HA.02 gas turbine in combined cycle.

GE Power now has 17 HA turbines commissioned and putting MW on the grid across five countries – France, Pakistan, Russia, Japan and the USA. Together, these turbines have achieved more than 50 000 operating hours.

According to GE Power’s estimates, an additional percentage point of efficiency in gas turbines can translate to millions in fuel savings for customers globally.

“When you talk about the cost of electricity, fuel can be anywhere from 50 to 80% of the cost of that electricity,” said Guy DeLeonardo, GE Power’s project manager for Advanced Combined-Cycle Platforms. “So, when we’re in Asia and we’re talking US$12 a million BTUs…Over a 20-year lifecycle, that 1% point is worth $50 million in fuel.”

The 9HA.02 can now be quoted at 64.0% net efficiency in specified conditions with total output of 826 MW in 1×1 combined cycle configuration. Customers can order HA-based combined cycle power plants quoted at 64+% this year, compared to the previous quoted limit of 63.7% efficiency for 2017 orders. In addition, GE Power remains on track to achieve 65% efficiency by the early 2020s.

GE’s long-term investments in additive manufacturing play an important role in the HA’s latest efficiency upgrades, DeLeonardo said.

“That’s where the advanced manufacturing and digital tools are true productivity drivers,” he said. “It’s not just that ‘oh, I get better costs’, there’s a complexity and capability I can avail now to design engineers by thinking in complete three dimensions, and if you want to think in the cooling microsurface channel cooling, which keeps the cooling close to the surface

“There are 3-D things that can bring the air in and out do it with digital tools that we do in conjunction with aviation. It’s that convergence that is working together to drive better economics as you go to 64 and 65%.”

That work is being done mostly in GE Power’s Advanced Manufacturing Works (AMW) in Greenville, South Carolina, USA, which opened in April 2016. GE plans to spend up to US$400 million across the GE Power Greenville campus over the next several years to drive innovation and the faster development of best-in-class technologies. The goal is to revolutionize the way GE Power designs, creates and improves products by serving as an incubator for the development of advanced manufacturing processes and rapid prototyping of new parts for GE’s energy businesses—Power, Renewable Energy, Oil & Gas and Energy Connections

DeLeonardo said the AMW allows GE Power to bridge the gap between R&D and production, which shortens the time from idea to implementation. The company recently marked its 10 000th additively printed part for power generation products.

Another success from AMW are the 3-D printed fuel nozzles for GE’s HA-class gas turbines. The company used metal 3-D printing to unlock new geometries for better premixing of fuel and air, leading to greater efficiency, DeLeonardo said.

“Engines always get hotter from more efficiency, so the challenge is being able to achieve emissions, specifically nitrous oxide emissions,” DeLeonardo said. “Supermixing, which is good for emissions and enables short flames, allows us to meet the nitrous oxide emissions at 64% combined cycle level and it has wider fuel flexibility.”

AMW is also leading to other changes, including to the supply chain.

“It’s infinitely scalable. Instead of shipping this to Europe, I’ll just ship a barrel of powder and a software program,” DeLeonardo said. “It will change the distribution of these parts, so the more that you can reach into a high gas path you completely change the supply side.”

Another advantage of the AMW is its full test stand, DeLeonardo said.

“Part of the test stand story is that we were able to unlock implicit capabilities in the engines,” DeLeonardo said.

Before any HA units are commissioned in the field, the new HA technology is tested GE’s validation test stand. Throughout that intensive process, the company found some places where improvements could be made. For instance, the tests gave GE an opportunity to optimize clearances in both turbine and compressor sections. The goal is to maintain positive clearance through all conditions, because tighter clearances leads to better performance. If clearance is not met, performance can be lost, or components will become damaged and create reliability issues, according to the company. GE was also able to adjust variable stator linkage to improve operability and make cooling flow changes to better manage component temperatures.

So, how far can the efficiency be pushed?

“It’s economics, first and foremost,” DeLeonardo said, noting that efficiency is only one attribute that customers are looking at when making a purchase. “You have to know that it works. “It’s like if your car is getting 40 mpg, but it’s in the shop every other week, it’s not going to work economically.

“You have to be able to demonstrate super running reliability, starting reliability, availability along with these types of efficiencies,” he said. “Is there an end? Again, it will be the economic shifts, but we see technologies that could go to 67%…so there are things that you can do between combustion—the hot gas path, cooling technologies—you start getting into more architectural things that are not fundamental little linear shifts better cooling better premixing.

But if you asked me—and this isn’t ahead of 2025—we could be 66 or 67% in 10 years,” he said. “That’s pretty cool, when you think about a (percentage) point a decade (improvement) traditionally.”

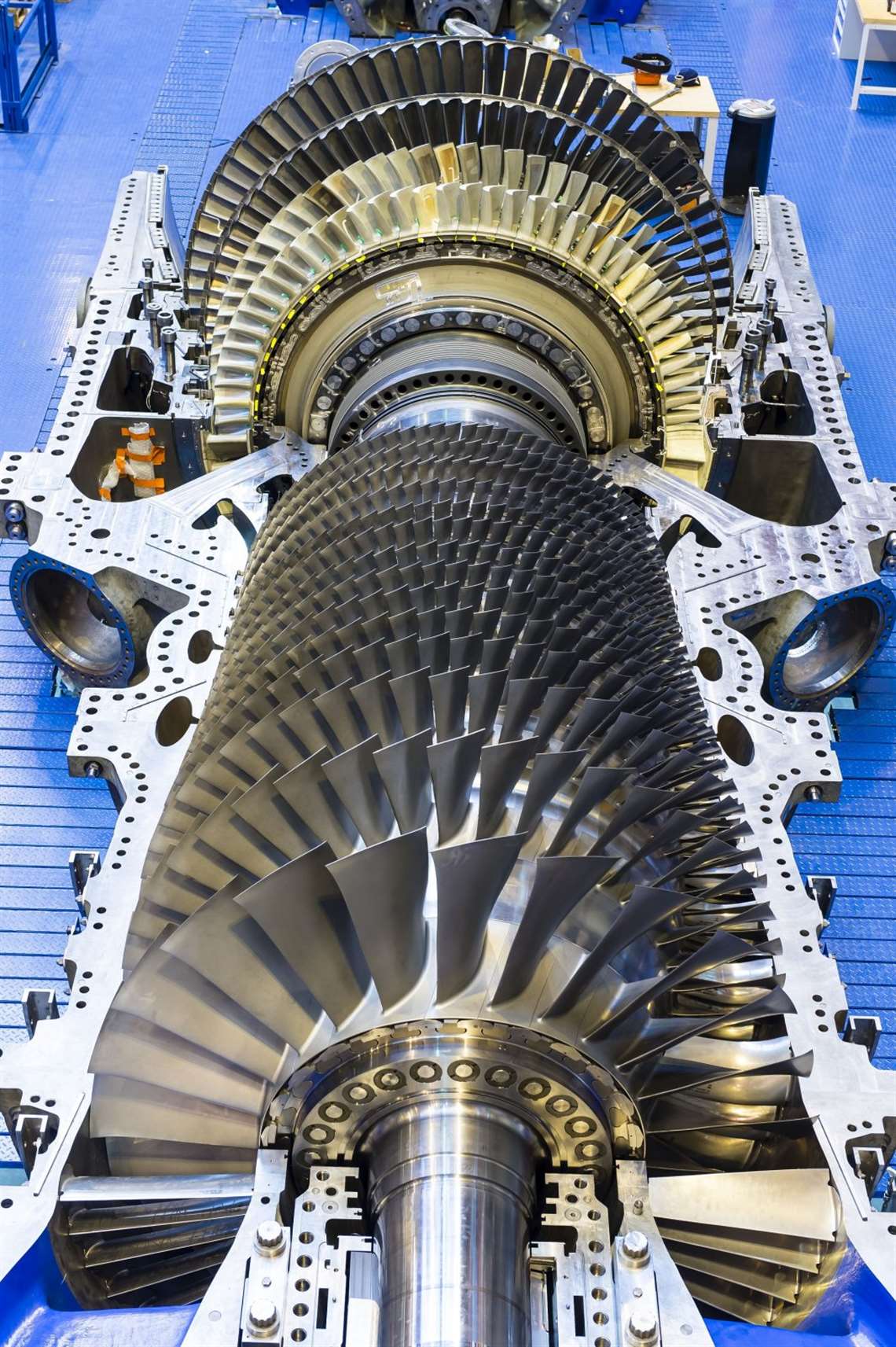

A 3-D printed component used on GE Power’s HA 9HA.02 gas turbine. The company said 3-D technology was key in driving efficiency improvements in the turbine.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM