Hannover Messe 2023 Review: Welcome home, pioneers!

05 May 2023

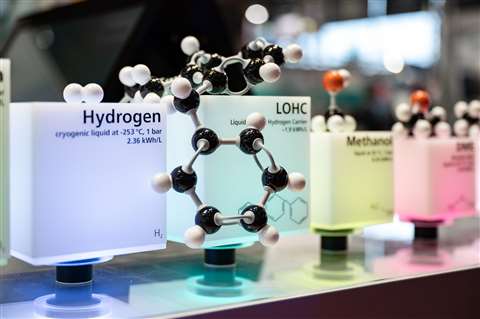

Hydrogen took centre stage at Hannover Messe 2023 (Photo: Deutsche Messe)

Hydrogen took centre stage at Hannover Messe 2023 (Photo: Deutsche Messe)

Hannover Messe, the annual industrial technology extravaganza organised by Deutsche Messe, serves as a launch platform for a wide variety of innovative products and processes. At this year’s event, more than 4,000 exhibitors presented their latest digital, connected and sustainability developments under the headline banner ‘Make the Difference’.

According to the organisers, about 130,000 visitors attended the latest edition of the show. “The five days of the trade fair have made clear that technologies for competitive and climate-neutral industrial production are available – now it is just a matter of developing the necessary speed and determination in the their implementation,” said Dr. Jochen Köckler, chairman of the managing board at Deutsche Messe.

While much of what is on display at Hannover Messe relates to manufacturing process efficiency, there was considerable interest in green energy production – these are technologies which can benefit a virtually limitless range of business sectors, including commercial transportation and construction.

Entry to this year’s Hannover Messe (Photo: Deutsche Messe)

Entry to this year’s Hannover Messe (Photo: Deutsche Messe)

Hydrogen from ammonia

As the green energy transition continues, hydrogen is set to play an increasingly important role. While Hannover Messe featured a series of companies with plans to launch fuel cells and related power systems (more on that later), a critical weak point in the hydrogen economy is where the fuel will be sourced.

There are a series of routes to producing hydrogen (H2) for fuel. The sustainability of the end product is noted in its colour code; where H2 from coal is referred to as brown or black, H2 sourced from natural gas can be grey, blue or turquoise, dependent on the process and energy source used to breakdown the methane. Green is the ideal colour classification for sustainable H2, identifying it as a product of water electrolysis powered by renewable electricity.

Currently there is no single process which will supply all the H2 needed to support a true hydrogen economy. That means, to varying degrees, all of the above will come into play as the demand for H2 fuel ramps up. In tandem, a series of hydrogen production processes will also be required, which was the driving force behind a process developed by a team at Fraunhofer IMM (Institute for Microengineering and Microsystems), in Mainz, Germany, which has created a reactor for cracking ammonia into hydrogen.

Model of ammonia cracker from Fraunhofer IMM (Photo: DPI)

Model of ammonia cracker from Fraunhofer IMM (Photo: DPI)

“Cracking ammonia is an endothermic reaction, so we’re using energy to produce hydrogen. But that only represents between 10 and 20% of the delivered hydrogen. This compares to about a 30% energy content currently needed for conventional H2 liquefaction,” said Dr. Jonas Schramm of IMM’s Hydrogen Technology Group.

Schramm continued by explaining that the resulting hydrogen then needs to be purified, essentially removing nitrogen and residual traces of ammonia. That involves a pressure swing absorption process, which separates the H2 from the other gases. The ‘off gas’ with any remaining ammonia can be redirected back into the cracking reactor to power the process, setting up a self-sustaining H2 production model.

“The recirculation delivers the very high efficiency of the reactor,” said Schramm. “The system also features several heat exchangers. That, for example, can be used to pre-heat the air used in the combustion process. The goal is to get the energy into the final product, not to heat up the reactor or its surroundings.”

The active section of the reactor features a series of microstructured stacked metal plates with catalyst coatings to support the combustion and cracking reactions on either side. The latest reactor at Fraunhofer IMM is designed to convert roughly 25 kg of ammonia into three kilograms of hydrogen per hour. “Our catalyst testing is carried out on small reactor plates coated with a catalyst and they’re proven to work for hundreds, possibly even thousands of hours with minimal degradation,” explained Schramm.

Dr. Jonas Schramm (left) and Dr. Gunther Kolb, Fraunhofer IMM (Photo: DPI)

Dr. Jonas Schramm (left) and Dr. Gunther Kolb, Fraunhofer IMM (Photo: DPI)

The next step will be to develop the prototype into a market-ready solution for the decentralised, carbon-free production of H2 fuel. There is also the need to source sufficient ammonia to support production. The gas is already used in fertiliser production, but it was noted that the plastics industry produces large amounts as a byproduct of polymer production. Ultimately, where the ammonia is sourced will dictate the colour grading of the final H2 product.

Electrolyser systems

Using an ammonia cracker has the potential to deliver useful quantities of fuel. But more ‘conventional’ technologies will be required to output industrial volumes of H2. At this year’s Hannover Messe, Rolls-Royce Power Systems presented its latest electrolyser technology as part of a complete hydrogen-powered ecosystem.

“There are two types of mature electrolyser technologies, alkaline and PEM,” explained Rohit Prasad, senior sales manager. “We elected to follow the PEM route, which led to the acquisition of a majority [54%] stake in Hoeller Electrolyzer. They developed the core stack and now we’re looking to industrialise that technology.” The new electrolyser is considered highly efficient; for an input of 1.6 MW there is about a 25% energy loss in terms of hydrogen produced, although some of heat output could potentially be reclaimed to improve that figure.

Rohit Prasad (left) and Alexander Buttler, Rolls-Royce Power Systems, with electrolyser model (Photo: DPI)

Rohit Prasad (left) and Alexander Buttler, Rolls-Royce Power Systems, with electrolyser model (Photo: DPI)

In the most basic terms, PEM, or polymer electrolyte membrane electrolysis, uses electricity to convert water into hydrogen and oxygen. A solid polymer electrolyte is used to conduct protons from the anode to cathode.

While Hoeller is behind the electrolyser stack tech, Rolls-Royce Power Systems provides the system integration. The integrated solution includes water purification, a critical necessity for best performance and longevity of the stack.

“It doesn’t matter where the water comes from, sea water or another source. But it must be purified,” explained Alexander Buttler, Hydrogen Product Solutions at Rolls-Royce Power Systems. “Any impurities will create a higher degradation rate and shorten the life of the electrolyser. We manage that integration, providing everything that’s required to make that electrolyser unit work safely and efficiently.”

The H2 produced by the stack is considered green when the system uses sustainable energy, or even pink when using electricity from nuclear. Rolls-Royce Power Systems is planning to prove out the technology with an installation at its headquarters in Friedrichshafen, Germany, with the resulting fuel used for testing fuel cells and hydrogen internal combustion developments.

Hydrogen ecosystem

Accelera by Cummins is the new business segment launched by the series internal combustion engine manufacturer to support development of its sustainable energy tech development. At Hannover Messe 2023, the division unveiled its complete hydrogen portfolio, described as an ‘end to end solution’ for the decarbonisation of transportation and other industries.

The system covers hydrogen production, through to storage and utilisation, for both mobile or stationary applications. On display at the trade fair was Accelera’s fourth-generation fuel cell, the FCE150, scheduled to enter production in 2025. Michael Sengpiel, senior sales director (Europe) for Fuel Cell and Hydrogen Technologies, gave DPI a walkaround of the latest H2 power system.

Michael Sengpiel, with the latest fuel cell stack from Accelera by Cummins (Photo: DPI)

Michael Sengpiel, with the latest fuel cell stack from Accelera by Cummins (Photo: DPI)

“[The FCE150] has one of the highest power densities in the market, 150 kW. The unit is flat, which makes it quite flexible in terms of installation. It can be mounted on a vehicle roof, or two can be combined and located in the engine bay of a 40-tonne truck. We’re targeting a much higher outlet temperature, up to 90ᵒC, in order to lower the heat load of the application.”

Up until this point, fuel cells produced by Accelera have been low-pressure units. The FCE 150 is the first to use variable pressure, which is controlled by an onboard turbo. “It’s not a turbo in the traditional sense as it’s not using exhaust gas, but that will come in 2027 with the next step in performance,” said Sengpiel. “Using reclaimed heat from the system we are targeting even better efficiency,” he added.

The prototype examples of the fuel cell have been hand built, but Sengpiel says that the company is investing in automated production. In addition, production of the membrane electrode assembly (MEA) has been brought in-house. The cathode catalyst layer contains platinum nano particles on a carbon base, an expensive but critical part of the fuel cell that is fundamental to the chemical process.

The company is targeting a working lifetime of more than 20,000 hours for the new fuel cell stack and Sengpiel noted that simulations have proved out the goal. He further explained that correct humidification of the H2 fuel (together with controlled start-stop protocols and optimised drive cycles) is a primary factor in getting the best from a fuel cell.

Battery recycling

The end goal of any hydrogen-based fuel system is to deliver electricity to an onboard battery pack so that energy can be directed to a motor that turns the driving wheels. But there are concerns that the anticipated volume of battery-electric vehicles over the coming years will put additional stress on raw material supply chains.

Battery recycling can bring new material streams to the industry, but current processes are slow and labour intensive. To address these issues, Bosch Rexroth introduced its new TS 5 transfer system for battery recycling at Hannover Messe.

Sebastian Krieger, Bosch Rexroth (Photo: DPI)

Sebastian Krieger, Bosch Rexroth (Photo: DPI)

The fully-automated system can analyse, transport and dismantle battery packs in preparation for recycling and reclamation of critical materials. The TS5 can also fully discharge the battery packs in advance of recycling, while also ensuring the chemicals within the packs are no longer capable of regaining any charge.

“The chemical elements within the battery cells can spontaneously generate small levels of power,” said Sebastian Krieger, senior manager, Assembly Technology. “The system takes away this possibility, helping to improve the full recycling process.”

The ctrlX Core and ctrlX Drive from the Bosch Rexroth modular toolkit are used to discharge the battery packs at a dedicated station. CrtlX Core controls the energy transfer and deep discharging, while ctrlX Drive takes that energy via an AC/DC converter and feeds it into either an intermediate circuit or back to the grid. The deep discharging process is followed by a chemical process which ensures full deactivation.

Bosch Rexroth system automates the first stages of battery pack recycling (Photo: Bosch Rexroth)

Bosch Rexroth system automates the first stages of battery pack recycling (Photo: Bosch Rexroth)

Compared to the previous manual discharge process, which takes about 24 hours, the automated process can be completed in less than 15 minutes. The deactivation further reduces any chance of a battery fire.

While discharging is critical to safe recycling, another issue is the sheer number of variations. Packs are produced with different exterior and interior designs, plus different closing and fixing solutions. Krieger said that the Bosch Rexroth system can identify and log the various pack types before they advance through the dismantling/discharge process.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM