Joint effort on machine telematics

16 December 2022

ydraForce, a global manufacturer of hydraulic values, manifolds, and eletrohydraulic systems, Tan Delta Systems, a supplier of real-time oil quality monitoring sensors and systems, and Elevāt, a global industrial IoT connected machines application provider, have combined to help eliminate the most common causes of off-highway machine downtime.

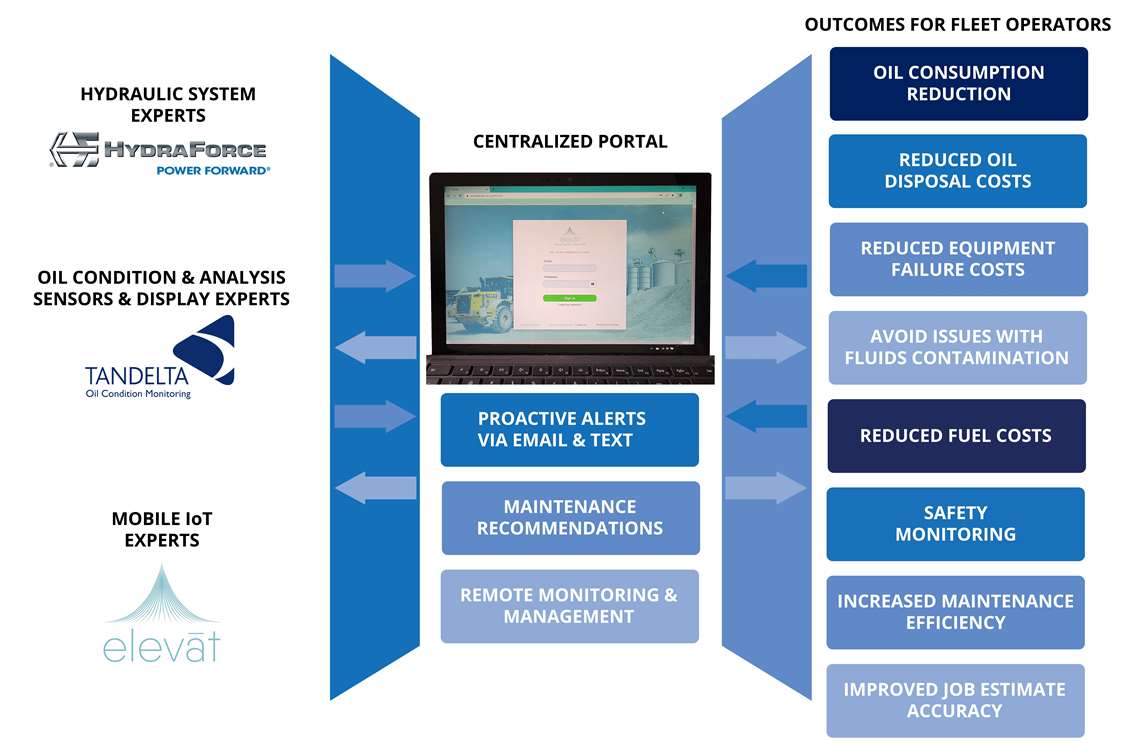

An infographic demonstrating how the integrated telematics solution supports fleet managers in remotely monitoring and managing field-deployed mobile assets. (Photo: Elevāt)

An infographic demonstrating how the integrated telematics solution supports fleet managers in remotely monitoring and managing field-deployed mobile assets. (Photo: Elevāt)

The mobile machine telematics solution from Elevāt integrates with manifold assemblies using HydraForce cartridge values and Tan Delta oil conditioning sensors.

The integrated solution is intended to provide a centralized portal along with email and text alerts to provide fleet operators with remote monitoring, control and optimization capabilities for field-deployed assets.

This new cooperation builds on the partnership between HydraForce and Tan Delta announced in late October.

“The team at HydraForce came to Elevāt because they wanted a solution that would support remote diagnostics, predictive maintenance, live updates and proactive telematics reports,” said Adam Livesay, co-founder of Elevāt. “They also wanted a fully integrated portal experience for fleet operators and mobile equipment manufacturers that delivers an easy-to-use interface and fast access to data and reports in a clear format so issues can be addressed before they impact machine operation. We are proud to be working with HydraForce and Tan Delta to deliver a solution that will maximize uptime and lower costs.”

“Elevāt’s Machine Connect application is paired with the Tan Delta oil conditioning sensors to provide operators with machine operational data and deliver customized alerts to inform the operator or owner when hydraulic fluids require maintenance,” said Russ Schneidewind, director of Business Development at HydraForce. “The combination of an electronic controller architecture with telematics, provides multiple benefits to users, including real-time data and ongoing alerts of oil conditions. The reported information will prevent excessive wear of hydraulic components and catastrophic failures that can occur when machines are in operation, thus, leading to increased productivity, and reductions in machine downtimes and maintenance costs.”

“Through accurate monitoring of oil health, maintenance scheduling can also be optimized as equipment is serviced only when required, and operators can rest assured that any unexpected changes in the oil condition will be immediately detected and reported,” said Chris Greenwood, managing director, Tan Delta Systems. “This can also extend the operational life of equipment and overall machine health, as optimal oil conditions prevent unnecessary wear and tear.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM