LPG-Fueled Ferry Completes HAZID Meetings

25 May 2017

GE’s Marine Solutions said that the world’s first liquid propane gas (LPG)-fueled ferry design to use GE’s COmbined Gas turbine Electric and Steam (COGES) system has successfully completed Hazard Identification (HAZID) meetings.

“Bureau Veritas, a world-leading classification society with a large and recognized expertise and experience in gas fueled ships, chaired the HAZID meetings. All consortium members were represented as well as SK Gas and E1, who are members of the Korea LPG Industry Association. These meetings took place over a three-day period in Busan and are a crucial tool used to identify hazards and safeguards at the early ship design stage,” said Brien Bolsinger, GE’s vice president, Marine Operations. “Now with HAZID meetings successfully completed, the consortium will proceed with securing a shipbuilding contract and will seek Approval in Principle to further validate the safety of the ship design including the COGES propulsion system and the LPG fuel supply.”

The consortium of Youngsung Global, DINTEC, Korea LPG Industry Association, GE’s Marine Solutions and Far East Ship Design & Engineering Co. signed a multilateral memorandum of understanding in November 2016 to cooperate on this unique ferry design.

Traditionally, a new ship design undergoes a series of processes from research and development to ship architecture and design, HAZID and AIP certification, and finally onto contracts with the shipyard and suppliers. Therefore, meeting HAZID requirements is considered a key milestone in ensuring the final success of the LPG COGES ferry design process, GE said.

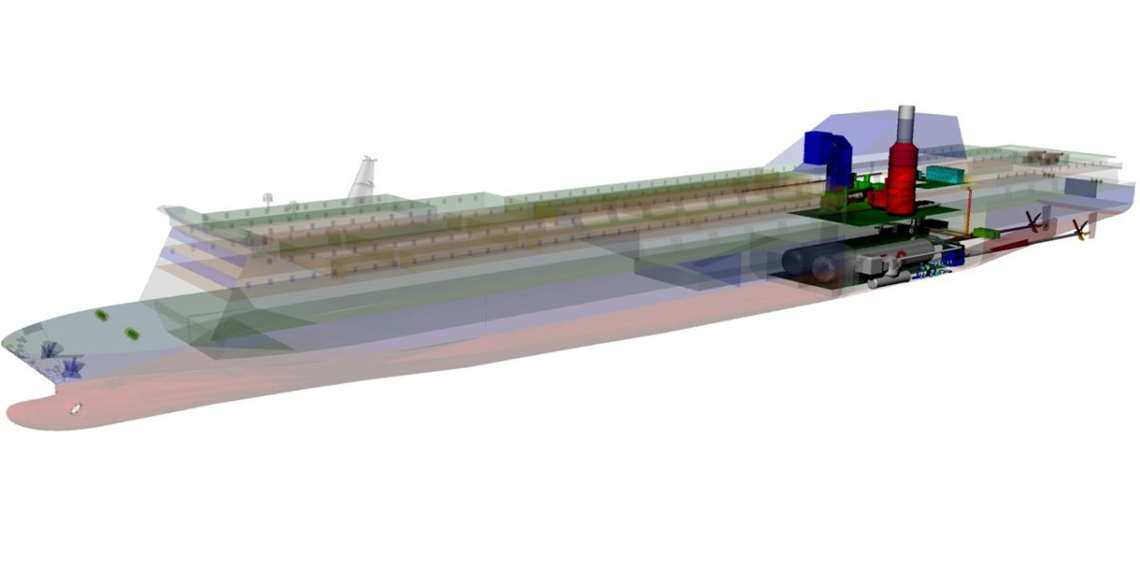

Increased use of LPG worldwide has made this ferry project feasible, GE said. The ship is designed to ensure both economic benefits and environmental performances, adopting LPG as the main fuel for lower fuel costs and no emission of sulfur oxides. GE said its compact and lightweight COGES system will provide for all ship power, including propulsion.

The COGES system consumes almost no lube oil and meets current and future regulations for SOx, nitrogen oxides (NOx), carbon dioxide (CO2) and particulate matter. Specifically, GE marine gas turbines meet International Maritime Organization Tier III and U.S. Environmental Protection Agency Tier 4 standards now without exhaust after treatment and no methane slip.

GE marine gas turbines are fuel flexible and can operate on a variety of fuels, including LPG, marine gas oil, biodiesel, bio-synthetic paraffinic kerosene blends and natural gas. The compact COGES arrangement allows for more revenue generating space on board ships and lower lifecycle costs. Maintenance of the COGES system requires only about 300 man-hours per year, and the entire turbine can be removed and replaced within 24 hours, reducing downtime for minimal interruption to ship operations.

GE marine gas turbines range from 4.5 MW to 52 MW output for ship power and propulsion. These engines operate worldwide for diverse commercial marine customers on cruise ships, fast ferries, high-speed luxury yachts, floating production storage and offloading ships and offshore platforms. In addition, over 1,400 GE marine gas turbines power nearly 500 military ships for 35 navies globally, logging some 14 million operating hours.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM