Mitsubishi releases IMO Tier 3 solution

11 March 2021

SCR system achieves regulatory requirements

Mitsubishi Turbocharger and Engine Europe B.V. (MTEE) said its new engine after-treatment solution complies with the IMO Tier 3 regulations by combining its proven mechanical engines with a certified selective catalytic reduction (SCR) system.

The SCR system is fully optimized and tested on cost-efficiency, quality requirements and meets the IMO Tier 3 environmental regulations.

“With this new solution we can offer our customers a cleaner auxiliary generator and propulsion system, compliant with the latest regulations and according to Mitsubishi standards, said Ron Slenders, MTEE’s product manager for Marine.

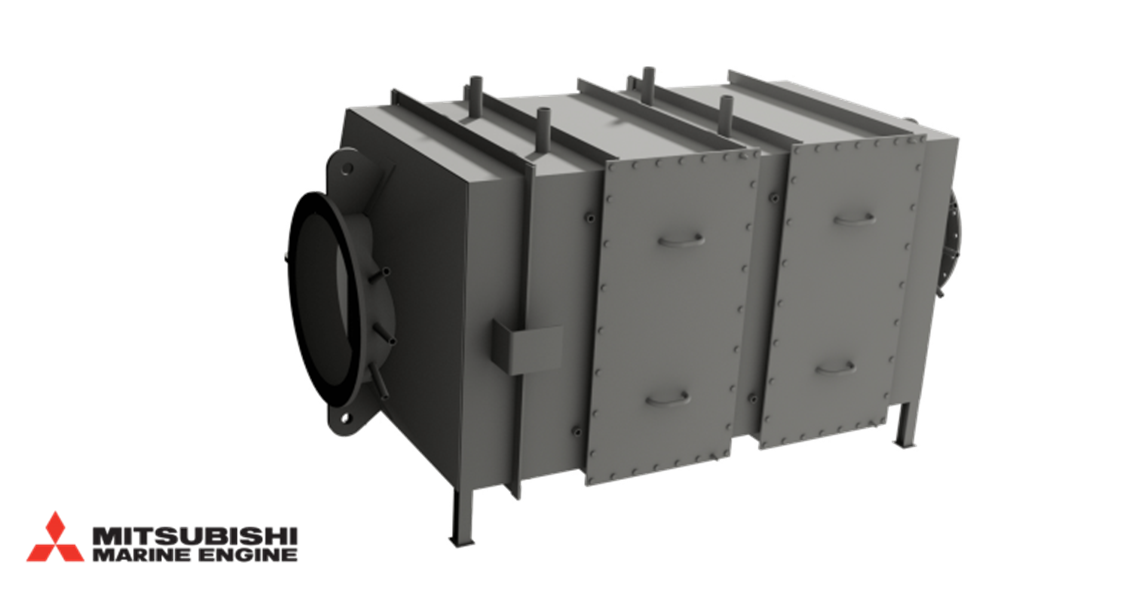

After-treatment solution from Mitsubishi Marine Engine.

After-treatment solution from Mitsubishi Marine Engine.

The first IMO Tier 3 certified product to be released with an after-treatment system is the S12R-MPTAW, a 12-cylinder auxiliary engine that is used in a wide range of marine applications such as ferries and tankers. The engine has an output of 1120 kW at 1500 rpm and 1154 and 1270 kW at 1800 rpm and is also available as a Mitsubishi Generator Set for marine. The next model that is now being tested and developed is the S12A2-MPTAW for propulsion (727 to 818 kW) and auxiliary generator (709 to 828 kW) application.

The SCR system is developed and customized to the specific engine and operations. This is done in close collaboration between MTEE engineering team, Mitsubishi Heavy Industries Engine Turbocharger Ltd. (MHIET), the global headquarter for Engine and Generator Sets of Mitsubishi Heavy Industries Group, and the SCR partner, GESAB. GESAB, based in Sweden, is an experienced partner offering SCR systems to the marine market for more than 10 years. The product quality, scalability and compatibility with MTEE’s full engine and generator set lineup, were key considerations in the selection process.

Next to the IMO emission tests and certification, extensive testing has taken place in-house to guarantee MHIET’s high-quality standards of the engine and after-treatment system. This to identify and solve risks at the earliest possible stage and ensure the quality of the system even under tough environmental and system conditions. The urea use is balanced for the exhaust gas to meet the IMO Tier 3 regulations, limit the ammonia slip and be highly cost-efficient. As the lineup is based on the IMO Tier 2 engines, it is possible to switch off the SCR system outside of the emission control areas to make the operations more economical.

The SCR system exists out of the SCR reactor, injection unit, dosing unit and soot blower system. The SCR reactor is available in a horizontal and vertical setup and has multiple connection points to create flexibility of installation. The full system is tested and certified in-house, ensuring a swift installation with no further certification requirements for the IMO Tier 3 regulations at the shipyard.

Beginning in January 2021, IMO Tier 3 regulations for commercial vessels with a total output of more than 130 kW has been in effect. The new regulation prescribes an average NOx reduction of 75% compared to the IMO Tier 2 levels for vessels operating in the North Sea and Baltic Sea Emission Control Areas.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM