MTA Braves High Voltage

01 March 2021

MTA explores the field of high voltage systems for electric and electric-hybrid vehicles.

MTA has been producing electric components for automotive applications and mobile machinery since 1954. Lately, one of the most pressing trends the company has registered, has been to move from low- and medium- to high voltage systems (where high-voltage is considered as over the threshold of 48V) a requirement for electric and electric-hybrid vehicles.

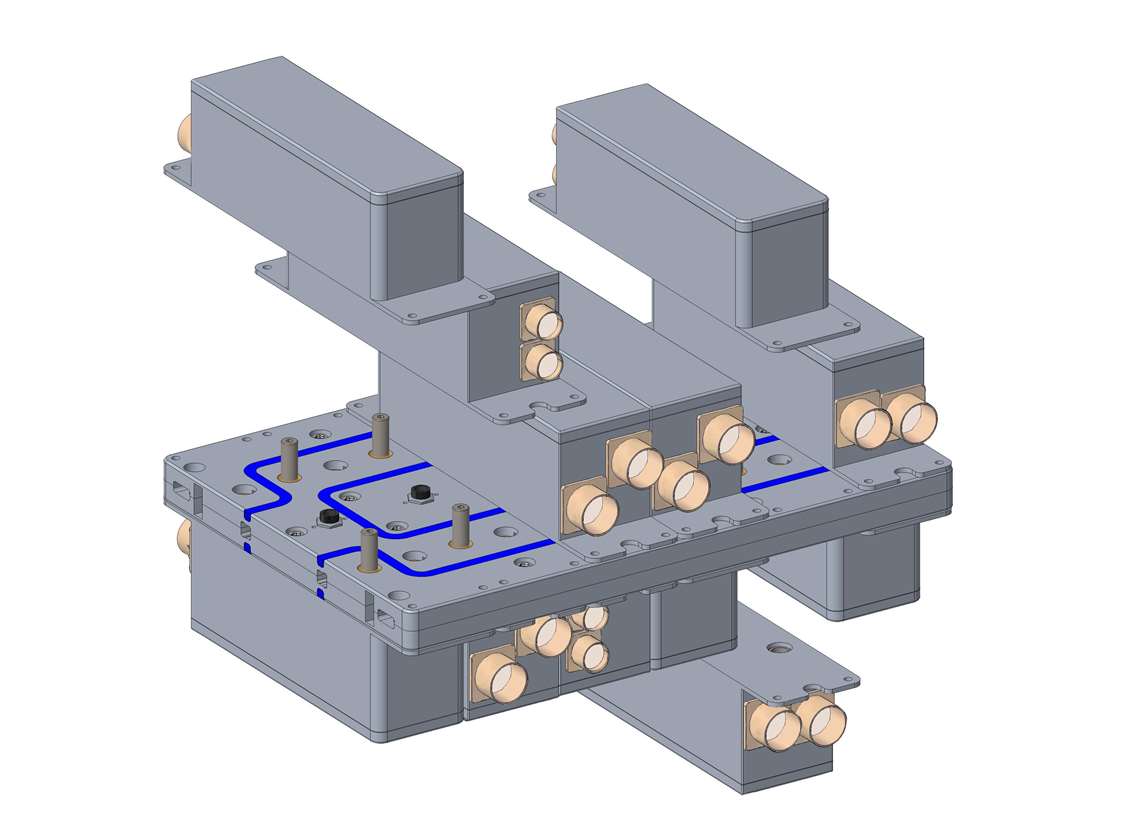

MTA’s modular PDU with integrated passive cooling systems for heavy-duty applications: it is made of aluminium plates and an internal resin layer for IP protection and electrical insulation.

MTA’s modular PDU with integrated passive cooling systems for heavy-duty applications: it is made of aluminium plates and an internal resin layer for IP protection and electrical insulation.

This new application field has required a major shift in R&D, purchasing and manufacturing, as explained by Fausto Biacchi, sales director working with MTA since more than 20 years: “R&D work had to concentrate on a complete new set of characteristics, as for example on respecting special safety regulations to deal with high voltage current that have to be added to existing standards. High-voltage Power Distribution units (PDUs) require specific materials – i.e. the standard for the housing is cast aluminium - so new suppliers had to be found and qualified.

“One of the most immediate difference to be noted when moving from low- and medium- to high voltage systems is the bigger size and consequently additional weight of the components: for example a fuse box, which in a low voltage architecture weights about 200/300 g, in a high voltage system can be 10 times heavier and reach up to 2 or 3 Kg or more.”

MTA put a lot of efforts in the research for this application field and invested also in the manufacturing processes that needed to adopt new techniques as in the case of special bays to safely accommodate the tests at the end of the assembly lines.

“While the shift to high voltage systems has been led by automotive requirements - as it almost always happen with new technologies for mobile machinery – there has been lately a pretty clear trend from other segments too,” said Davide Bonelli, MTA’s sales director and a specialist for the Off-Highway market. “Some industries as construction machinery and agricultural vehicles are being less impacted for the time being, even though the interest from the OEMs is pretty lively; on the other hand, the market of heavy-duty trucks is showing a clear activity with a number of projects in development for major global OEMs.

Francesco Sabella, project leader electric applications at MTA, is very much involved in research and development work for high-voltage projects in trucks. He explained the latest developments for heavy-duty research projects include a modular PDU with integrated passive cooling systems (connected to the vehicle’s cooling system). “The PDU is very flexible and adaptable to several truck platforms,” said Sabella. “It is made of aluminium plates and an internal resin layer insures Ingress Protection (IP) and electrical insulation.”

There is also a series of PDUs with integrated electronic components that can manage the communication protocols for the electric recharge stations: an Aux PDU and a Front PDU, both being developed for major electric truck manufacturers, whose names cannot be disclosed at this time; and a Rear Junction box to be mounted in the rear of the truck.

All these components are equipped with a 12V safety circuit and the rear junction box includes an additional safety circuit which interrupts the current flow when the box cover is opened.

This story first appeared in the January/February 2021 issue of Diesel Progress International. To subscribe click HERE.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM