New Equipment Expands IEA Manufacturing Capabilities

28 September 2020

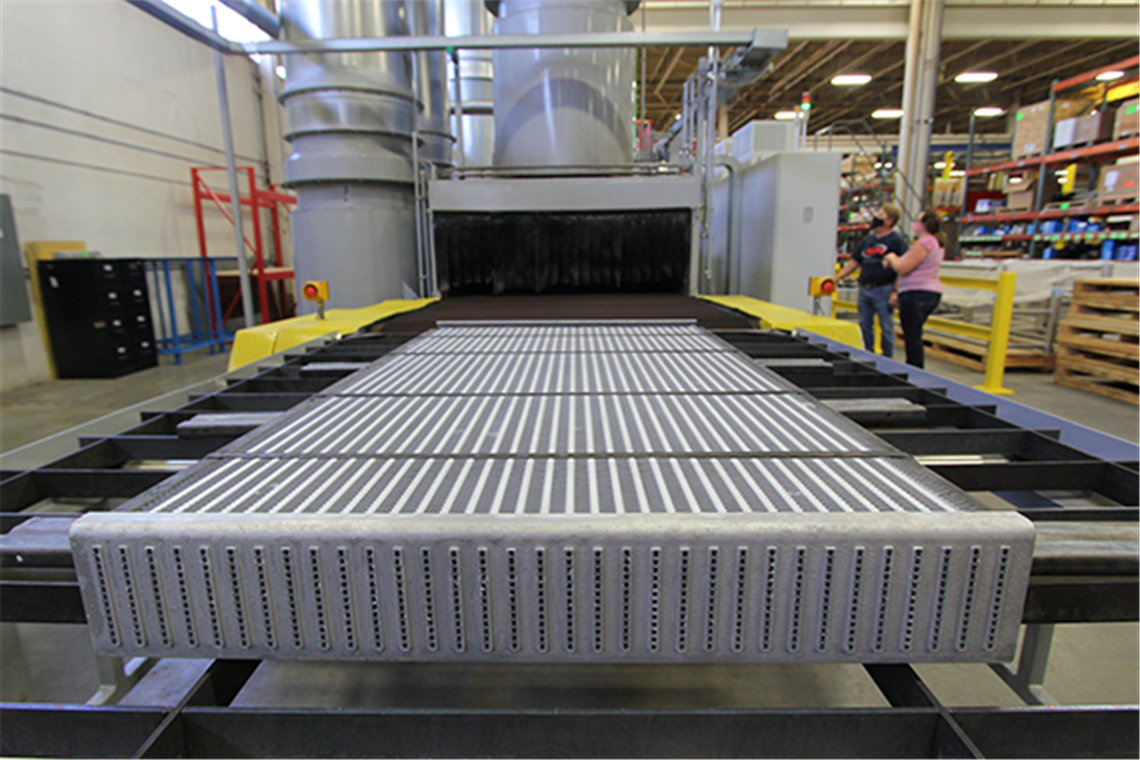

IEA, the Kenosha, Wis.-headquartered manufacturer of radiators and heat exchangers for stationary and off-highway diesels, announced it has expanded its Kenosha-based manufacturing capabilities with the purchase and installation of an aluminum brazing furnace. The new furnace completes IEA’s ‘Made In USA’ cooling solution with a complete, domestic offering of aluminum heat exchangers complimented by the indexed, tube-fin and plate-fin copper-brass models already available, the company said.

The controlled atmosphere brazing furnace also furthers the company’s vertical integration initiatives for the production of aluminum heat exchangers in all sizes, IEA said, while re-shoring production operations that were previously sourced from international suppliers.

“Most of the applications for our products are truly ‘mission critical,’” said James Kettinger, IEA president and CEO. “We take that responsibility very seriously. As a result, we are more vertically integrated than ever before because ‘Made in America’ means more than ever. We control the design, supply, manufacturing, quality, testing and performance of everything we produce.”

IEA integrates aluminum or copper/brass heat exchangers in every mobile, industrial, and power generation cooling system it offers and, by the installation of the new furnace, has vertically integrated production of a critical component of its products.

IEA said its expanded capabilities optimize the supply chain for customers in many facets. Collaboration with IEA for new aluminum-core product designs will be faster than ever, allowing for rapid prototyping and short lead times for new and replacement parts. Additionally, domestic, vertical integration protects IEA’s customers from tariffs and economic disruptions abroad.

“IEA is always looking for new and innovative ways to deliver value to our customers,” said Kevin Rafferty, IEA vice president, Business Development. “I am thrilled that IEA will be able to do just that with the commissioning of our aluminum furnace in our Kenosha facility. We further fulfill our customer’s needs by having a domestic furnace that offers more options.

“IEA will now be able to provide shorter lead times, manufacturing flexibility, local engineering and a reduced reliance on overseas aluminum supply, while at the same time, offering world class pricing from our overseas supply chain for applicable orders.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM