New horizons for alternators with Linz Electric

13 November 2023

Alternator specialist Linz Electric explores new application fields and markets.

Founded in 2016, the Grimes, Iowa, facility handles all sales activities, pre- and post-sales, for the U.S.

Founded in 2016, the Grimes, Iowa, facility handles all sales activities, pre- and post-sales, for the U.S.

Having celebrated its 20th anniversary last year, Linz Electric is taking stock of its busy past as it prepares for a much more complex future, involving expansion into new markets and the development of new alternators to target application fields beyond the more traditional ones connected with power generation.

The company was founded in 2002 near Verona in northern Italy by engineer Giulio Pedrollo and today is part of the Pedrollo Group, whose alternators are also well-known and appreciated in over 80 countries around the world by manufacturers of generator sets.

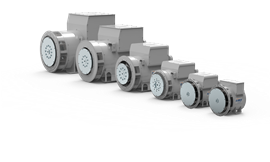

All alternators by Linz Electric are manufactured in Italy using advanced manufacturing technologies, quality materials and highly automated production lines.

Market expansion

The U.S. has been an important market for the company’s expansion. A subsidiary based in Grimes (Des Moines), Iowa, was founded in 2016. Today, it handles all sales activities, pre- and post-sales, for the U.S., as well as the stocking of parts.

Sandro Alberghini, president of Linz Electric’s U.S. subsidiary, explained that a local facility that oversees all aspects related to the local market was key to the company’s success in the region.

“A large portion of our business in North America is connected to applications that are often in remote sites, for example oil & gas facilities or telecommunication towers. Being able to react quickly to any need of the customer post-sale is definitely a must,” he said, underlining how Linz Electric decided to go to market directly without using local distributors.

The company’s product range includes alternators for use in power generation, integration as part of machinery and applications related to the energy transition.

The company’s product range includes alternators for use in power generation, integration as part of machinery and applications related to the energy transition.

The company’s product range has three major application areas. The first is the well-established market of power generation, for both stationary and mobile gen-sets for industrial applications, construction, telecom, oil & gas and marine and power take-offs (PTOs) in agricultural vehicles.

The second is related to special applications where the alternator is an integrated component in machinery. It is intended to power a specific load such as in lighting towers (one of Linz Electric’s major application markets), asphalt machinery, APU or reefer units.

The third market is related to applications for the energy transition, for example, hybrid systems, battery recharging systems, power generation with biomass, cogeneration and tri-generation.

George Sursal, the company’s U.S. sales director, summarized the major product ranges in the company’s product portfolio:

- A wide range of two- and four-pole synchronous brushless alternators with different types of voltage regulation and provided with auxiliary winding.

- The Alumen series, originally intended for lighting towers, is a family of single-phase, four-pole brushless alternators with an auxiliary winding to regulate the voltage loaded onto highly insulated capacitors to protect from high ignition voltage. The Alumen alternators are available in four models with power rating from 4.2 to 10 kVA in the 60-Hz variant.

- The Compatto series of four-pole, brushless, compact alternators with exciter and automatic voltage regulation (AVR) used for continuous service applications such as gen-sets and other industrial applications, and in harsh ambient conditions such as dusty, humid and saline environments and high temperatures. This series covers from 7 to 30 kVA for 60 Hz and is especially appreciated in the U.S. for marine applications.

- The Phase9 direct-current (DC), low-voltage alternator series is composed of synchronous brushless alternators with nine-phase windings that ensure a very stable voltage after conversion to DC (residual ripple below 1%). This makes these alternators ideal with hybrid systems using batteries for various applications and for recharging systems of batteries of any kind.

Linz Electric Founder Ing. Giulio Pedrollo now serves as CEO for the Pedrollo Group, and chairman of Pedrollo Group Inc. (USA). (Photo: Zoppas)

Linz Electric Founder Ing. Giulio Pedrollo now serves as CEO for the Pedrollo Group, and chairman of Pedrollo Group Inc. (USA). (Photo: Zoppas)

The opening into new application markets has placed an increased emphasis on the electronics that are needed to manage more complex systems in various market sectors.

One example is the development of the HVR-BMS automatic voltage regulator range, which makes it possible to manage the AVR directly from the battery in hybrid systems.

Alberghini emphasized that the company’s strengths lie with a product design that is modern and quality oriented, but also with manufacturing characteristics such as its 100% production in Italy and European-based supplier basin, as well as its flexibility in production and delivery including when it comes to smaller production batches.

All these aspects enabled Linz Electric to bring its anniversary year 2022 to the threshold of over 100.000 alternators sold, with further substantial growth expected for 2023.

Investment in innovation

Alberghini noted how Linz Electric’s relation to the Pedrollo Group means a great commitment to innovation and to investing in R&D and new manufacturing technologies.

On average, over 15% of yearly revenues are re-invested into the company and this is clearly seen by the high automation of manufacturing processes in-house.

“Linz Electric is one of the alternator manufacturers using more aluminium components in its products,” said Alberghini. “The use of aluminium has a very high initial manufacturing cost related to the casting dies, but results in a very efficient and cost-effective product for the end user. Such investments have been possible thanks to the financial solidity of the Pedrollo Group.”

Linz Electric is also further expanding its manufacturing plant at the Italian headquarters with the addition of a new production hall dedicated to winding operations, which will allow it to further increase production capability and serve customers with the necessary flexibility and care.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM