31 January 2025

Q Hydrogen is about to launch commercial hydrogen production using its all-new proprietary technology. Julian Buckley spoke with Whitaker Irvin, Jr., president and CEO, to find out more details

(Photo: Adobe Stock)

(Photo: Adobe Stock)

A decade of intense R&D to develop robust and efficient technologies using hydrogen as the primary fuel source is set to deliver a series of new power solutions ready for commercial applications.

Heavy goods vehicles fitted with hydrogen internal combustion engines (H2 ICEs) are now being delivered to customers; models powered by fuel cells should be available in a year or two. Construction machines using similar technologies are set for imminent launch. Elsewhere, trains powered by electricity generated using hydrogen fuel cells are already in limited operation.

Yet as these technologies move along the development pipeline towards market readiness, the question about where the hydrogen fuel will be sourced remains largely unanswered. Existing sites produce only very limited amounts of H2 and although various national governments have launched funding initiatives intended to drive major H2 production projects, these are years from delivering any meaningful volumes.

Such the scarcity of hydrogen that in September 2024, a German rail operator had to switch back to diesel trains when it became impossible to source the fuel for its new hydrogen-powered rolling stock.

Hydrogen production

There are a series of methods for releasing hydrogen for use as fuel, but most involve either electrolysis or pyrolysis. Looking at electrolysis, the process uses an electrical current to split water into hydrogen and oxygen. Pyrolysis uses heat to separate the H2 from a source material.

Whitaker Irvin, Jr., Q Hydrogen

Whitaker Irvin, Jr., Q Hydrogen

Both have drawbacks related to the energy needed to drive the process; for its part, electrolysis demands ‘green’ renewable electricity to deliver green hydrogen. Pyrolysis requires a high temperature which at the very least needs a suitable ignition source – in one case, Fraunhofer IMM (Institute for Microengineering and Microsystems) has developed an ammonia pyrolysis procedure which, once initiated, is said to be largely self-sustaining in terms of heat.

Whitaker Irvin, Jr., president and CEO of Q Hydrogen, says that the company has developed an all-new process for hydrogen production which uses far less energy than either of the above, although he says the tech was not originally developed to produce hydrogen at all.

“The technology developed by my father dates back to 2007, it was intended to deliver a new method of providing industrial heating and cooling. The idea was to create two differentiated air flows, a hot side and a cold side, using hyperbolic waveform geometries. These [geometries] were positioned on fixed turbine plate surfaces in a mirror arrangement - they would ‘nest’ if brought together - but with a slight gap between them. Pushing air through this setup creates an environment where high- and low-pressure zones are interacting in a clockwise and counterclockwise motion, with the goal of having a reaction [temperature change] within the non-ferrous metal turbine.

“We expected a temperature difference of between 10 and 20ºF. But what we got was much greater, about 147ºF on the hot side and 37ºF on the cold side. All in a unit which was about six inches wide and 12 inches tall. That was the first clue there was something more powerful going on.”

What’s in a name?

According to Whitaker Irvin, the ‘Q’ in Q Hydrogen stands for QuasarWave. This is the parent company of the hydrogen production business and holding company for the related technology.

In nature, the vast majority of galaxies have a super-massive black hole at their centre. A quasar is a super-massive black hole which emits intense energy levels across the electromagnetic spectrum, while also sometimes emitting the characteristic jets of material from each pole.

“That’s the idea behind the name, that the technology is attempting to harness just a very small part of the power represented by ideas such as string theory and quantum theory,” explains Irvin.

Continuing, Irvin says that about a year later, during a test of the system in a sealed chamber, an open valve allowed moisture into the test unit. The valve was opened the next day and, as Irvin recounts: “There was a boom! Hydrogen had formed from just the moisture in the air interacting with the plates of the turbine; it wasn’t even spinning.”

A system was added to allow the addition of measured amounts of moisture and subsequent testing ultimately determined that the unit could produce hydrogen gas. In 2014 the decision was made to commercialise the process, which resulted in the first turbine intended to process water and produce hydrogen.

Irvin says that clockwise/anticlockwise streams within the unit create high- and low-pressure zones which in turn produce high-speed vortices. It is this environment which is key to producing hydrogen gas.

The Q Hydrogen location in Groveton, New Hampshire (Photo: Q Hydrogen)

The Q Hydrogen location in Groveton, New Hampshire (Photo: Q Hydrogen)

“Essentially, you’re creating a lot of spin on whatever the material is within the turbine,” he explains. “There’s a bit more detail, a couple more process elements that we plan to reveal soon, but that’s one of the keys.”

With the caveat that “this will probably sound pretty corny”, Irvin continues by saying that global energy production up until now has largely been focused on heat-related processes. But he states that nature has given us a series of solutions which have the potential to create energy without a chemical reaction: “We only have to be open minded enough to take advantage of what’s there.”

New England energy

The research and development process has been carried out at a laboratory in Utah. But the first finished hydrogen production units will be located at a facility in New Hampshire.

According to Irvin, the decision to base production in New England relates to the increase of energy costs in the northern United States. With the hydrogen production site he is hoping to deliver electricity at a similar price point to PPAs (Power Purchase Agreements), rates which are more usually found in southern and western states.

“We’ve had a lot of support from the community and the state [of New Hampshire]. We’re anticipating opening the facility this year, hopefully in the first half of this year,” he says.

The first customer for the plant will be a mobile data centre. Moving forward, there are plans to provide hydrogen to paying customers. This could include maritime companies which could use the hydrogen to support engine decarbonisation and achieve IMO 3 compliance. Future projects could see disused coal-fired power stations adapted to use hydrogen and brought back online.

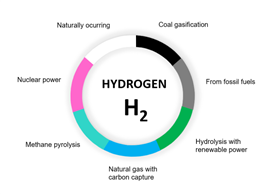

Hydrogen colour chart (Graphic courtesy of the Journal of Petroleum Technology)

Hydrogen colour chart (Graphic courtesy of the Journal of Petroleum Technology)

Clear Hydrogen

Hydrogen is classified by colour dependent on its source and production process. For example, hydrogen produced using water electrolysis powered by renewable electricity (wind, solar, etc.) is considered ‘green’. Blue H2 is largely produced from natural gas, while pink H2 is produced using nuclear energy. Grey hydrogen comes from other fossil fuels.

Due to the low energy requirement and lower cost, the gas produced using the process developed by Q Hydrogen has been dubbed ‘Clear Hydrogen’.

Once up and running, the plant in New Hampshire will have the capacity to produce up to 100,000 kg of Clear hydrogen per day and it is this fuel which will be used to deliver energy to local and regional customers.

Going back to New Hampshire, Irvin explains that electricity will come from a series of gaseous-fuel [3016] generators from Caterpillar which have been adapted to use hydrogen.

“Caterpillar is developing their own hydrogen gen sets, but we had to do this on our own due to the timing of the Caterpillar units. These units are a first step and not representative of the most efficient use of our fuel. We’re working through use cases with combustion laboratories and have made significant advances with fuel cells, fuel storage and improved transportation techniques for the product.”

By way of explanation, Irvin goes on to say that the Q Hydrogen product is mostly hydrogen, but has very minor concentrations of other elements which help to support a wider range of industrial uses.

“I know I’m being a bit nebulous, but we’ll release details about this as well,” he adds with a smile. “We’ve found some really cool things that you can do with hydrogen that you can use in a lot of areas.”

Energy loss

The energy used in the water electrolysis process results in a 20 to 30% reduction in the total energy value of the final hydrogen product. Asked about the related energy loss using the system developed by Q Hydrogen, Irvin says the energy inputs are “minimal” when compared to existing production methods.

“That’s how we can produce the fuel onsite, use it in a highly-inefficient gen set and still expect to make a profit.”

The IRA, or Inflation Reduction Act of 2022, offers production credits for each kilogram of ‘qualified’ clean hydrogen produced at a qualified production facility. Irvin: “I’m glad the IRA exists because it’s given a voice to the technology and hydrogen space that’s been around for a long time, but needed a push – like solar and wind. We’re going through the process, but it has never been the focus to rely on subsidies.”

“Essentially, you’re creating a lot of spin on whatever the material is within the turbine. There’s a bit more detail, a couple more process elements that we plan to reveal soon, but that’s one of the keys.” Whitaker Irvin, Jr., Q Hydrogen

Such is the efficiency of the proprietary production method that while Q Hydrogen will take what government subsidies are available to support production of H2, the company could operate profitably without any financial assistance.

In response to those who might say a given energy type should be used in its original format to avoid unnecessary energy loss, he says that while energy from wind and solar is generally better in its original form and not used to electrolyze water, not every geographic location has that choice. Plus, the tech is still in its infancy.

“The potential energy contained in a drop of water is massive. I believe there was a study that found if you could efficiently potentiate all the energy from a drop of water it could power San Francisco for a period of time. I believe that’s true, but we’re only at the start of a journey which might end up there.”

Future path

The general view today is that hydrogen has a role to play in the future fuel mix, but only alongside existing options including natural gas, diesel, petrol and electrical power. But Irvin believes that hydrogen will be a “massive player”, with technologies like that developed by Q Hydrogen altering the existing H2 usage trajectory.

“I just got back from attending government meetings in Ireland, they were talking about how demand is creating power shortages. In the US, some proposed data centres have grid interconnect dates seven or 10 years in the future because there’s no capacity as yet. I think that hydrogen can help solve these problems; I think there’s the potential for new data centres which are completely off the grid and supported by hydrogen.”

Hydrogen pipelines likely to be part of a hub and spoke setup (Photo: Adobe Stock)

Hydrogen pipelines likely to be part of a hub and spoke setup (Photo: Adobe Stock)

There are other competitors in the ‘remote’ energy market, including low-energy nuclear reactors. Irvin thinks that these will have a role to play, influenced largely by geographic location. “There will be space for micro nuclear plants and hydrogen, but they will impact the market in different ways.”

With regards to delivery, he says that there is potential for a national hydrogen pipeline, but one of the factors that would support this is the state of the final product.

“The hydrogen we produce would lend itself to being delivered via a pipeline. But in reality, I think production will be based on a hub-and-spoke model. It would be very expensive to contain and push hydrogen gas or cryogenically-cooled liquid hydrogen through a pipe.”

Like the production tech, Irvin adds that Q Hydrogen will release more details about possibly delivering hydrogen via a dedicated pipeline at a later date.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM