New Power Progress Yearbook showcases suppliers for electrification

13 August 2021

The 2nd Yearbook, providing a snapshot of July 2020 to July 2021, has become an annual reference of choice for those looking for information about the electrification of anything from last-mile delivery vehicles to mine haul trucks. Chad Elmore reports.

“We are fuel agnostic” is something that you can expect to hear from Diesel Progress staffers at trade shows or in meetings, especially when one of our business cards or an e-mail message lands in the hands of someone developing lithium-ion battery packs.

The industry has evolved since this magazine was founded in 1935, and so too has our editorial content and the way in which we connect with readers and advertisers. When it comes to the fuel source that makes all of this equipment function, we like it all.

Decision-makers who read Diesel Progress still buy a lot of engines – biodiesel, diesel, gasoline, methane and natural gas – and will continue to do so for the foreseeable future. However, the majority are also looking for a path to, and through, the world of electrification. With that reality in mind, the June issue of Diesel Progress carried the 42nd Engine Yearbook.

Folks in the dreamer, engineering, investor and marketing communities all see an opportunity in the battery electric vehicle and the hydrogen fuel cell electric machine, which makes for a dynamic landscape. The amount of news that this segment of the market generates is enough to keep one up at night.

There is a plethora of suppliers, from start-ups to established manufacturers – some were not even around for the 2020 edition of the New Power Progress Yearbook. And each claim that they are ready to assist in the development of an electric machine that is reliable, robust, safe and saleable.

6SYNCT CONSULTING INC.

Consultants focused on electrification in off-highway machinery.

Midland, Ontario, Canada

Web: www.6synct.com

News for 6Synct Consulting

The company selects the best solutions for each customer, boasts clients throughout North and South America and across the world. 6Synct claims that it uses an agile approach and does not supply one specific system to OEMs or end-users.

Past and present projects include:

- Innovative Vehicle Institute.

Prototype testing expected in spring 2022 at the Nouveau Monde Graphite site; - Komatsu.

Project management, technology guidance for the electrification of underground equipment; - Nouveau Monde Graphite.

Developing the tools, team and proof-of-concepts to adopt electrification for the first all-electric mine, and; - Teck.

Assess technology readiness of electric vehicles for mine operating conditions and duty cycles.

ALLISON TRANSMISSION

Hybrid transmissions and electric axles for medium- and heavy-duty vehicles.

Indianapolis, Indianapolis, USA

Web: www.allisontransmission.com

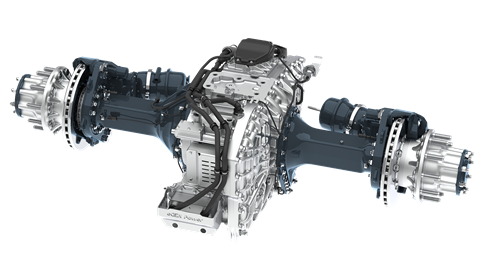

The eGen Power electric axle from Allison Transmission

The eGen Power electric axle from Allison Transmission

News for Allison Transmission

Originally designed and developed for buses, Allison stated that its eGen Flex avoids the inconvenience of having a limited range by deploying electric propulsion selectively and tops-up batteries through regenerative braking.

Their eGen Flex is expected to go into production in January 2022, replacing Allison’s H40/50 EP electric hybrid system. It builds on the H40/50 EP electric hybrid propulsion system to provide engine-off electric hybrid operation. Lithium-titanate (LTO) battery technology enables electric propulsion for up to 10 miles.

Allison’s eGen Power is a new series of fully integrated electric axles designed to fit between the wheels of trucks and buses and replace the vehicle’s traditional powertrain system. This bolt-in solution has fully integrated electric motors, a multi-speed gearbox, oil cooler and pump. The system is compatible with full battery electric vehicles, fuel cell electric vehicles and range extending hybrid applications.

The company said that its new eGen Flex electric hybrid propulsion solution, will be put into revenue service at New York City Transit (NYCT). GILLIG will offer the eGen Flex electric hybrid propulsion system on its buses.

Rohan Barua, vice president of sales for North America at Allison Transmission, explained, “GILLIG and Allison have established a joint partnership dedicated to optimized integration and a mutual commitment to innovation.

“We are excited to continue our history of innovation with Gillig through the launch of the eGen Flex propulsion system. The diesel engine can serve as a range extender, when needed for longer routes or route flexibility due to unplanned congestion or construction on routes.

“Through this solution Gillig and Allison can offer customers full EV capability while maintaining a diesel engine for added flexibility, effectively serving as a bridge solution to EV.”

Gillig stated that it has received its first order for eGen Flex electric hybrid-equipped buses from IndyGo, the Indianapolis Transportation Corporation.

Allison Transmission announced in April 2021 a strategic Memorandum of Understanding (MOU) with Emergency One (UK) Ltd to integrate the eGen Power 100D electric axle into fire rescue and emergency vehicles.

The electric axle integrates two high-speed electric motors and a multi-speed transmission, eliminating the need for additional driveshafts and support structures. It provides continuous power of 536 hp and peak output power of 738 hp. The company revealed that the eGen Power 100D is the first in a lineup of electric axles.

BAE SYSTEMS

Low and zero-emission electric drive propulsion systems for battery-electric, hydrogen fuel cell and electric-hybrid solutions.

Endicott, Broome County, New York, USA

Web: www.gettozero.com

BAE Systems has introduced its next-generation full battery electric power and propulsion system for transit buses

BAE Systems has introduced its next-generation full battery electric power and propulsion system for transit buses

News for BAE Systems

Some 15 public buses in Vancouver, British Columbia, Canada, will be fitted with BAE Systems’ all-electric propulsion system based on electric motors, controls and batteries.

The company said in March 2021 that the fleet is the first in North America to use its next-generation Series-EV all-electric propulsion system, which uses fewer, lighter and more compact components. BAE Systems claimed that the light weight, reduced number of connections and use of advanced materials make it easy to install and efficient, which enables the buses to travel longer distances on a single charge.

Series-EV builds on more than 25 years of innovation and proven technology that powers buses all across the globe. The company’s all-electric systems are on buses in service throughout Europe.

BAE Systems announced that it was collaborating with Plug Power, a supplier of hydrogen engines and fueling systems, to offer hydrogen-based electric propulsion systems for transit bus fleets. The companies will collaborate to offer transit operators in North America an all-inclusive, scalable system to reach zero emissions, providing required site, service and vehicle solutions.

BAE Systems will integrate Plug Power’s fuel cell engines into its electric drive systems to power the bus. The strategic partnership leverages the combined knowledge and experience in electrification of each company.

BALLARD POWER SYSTEMS

PEM (proton exchange membrane) fuel cell systems for buses, commercial trucks, trains, marine vessels, passenger vehicles, forklift trucks and UAVs.

Vancouver, British Columbia, Canada

Web: www.ballard.com

Ballard’s 30kW FCveloCity-MD fuel cell power module was developed for use in heavy-duty motive applications

Ballard’s 30kW FCveloCity-MD fuel cell power module was developed for use in heavy-duty motive applications

News for Ballard Power Systems

Ballard Power Systems announced in June 2021 that it received an additional purchase order from New Flyer for 20 fuel cell modules to power Xcelsior model fuel cell electric buses for deployment with Alameda-Contra Costa Transit District (AC Transit) in Oakland, California.

Deployment of the New Flyer buses will bring the total number of Ballard-powered buses operated by AC Transit to 31.

Ballard Power Systems and Linamar Corporation formed a strategic alliance in May 2021 for the co-development and sale of fuel cell powertrains and components for Class 1 and 2 vehicles, weighing up to five tons, initially in North America and Europe.

In the initial phase a fuel cell powertrain will be developed, with Ballard providing the fuel cell subsystem and Linamar providing both the rolling chassis and final assembly.

Following successful testing, Ballard and Linamar may contemplate the formation of a joint venture to sell and support powertrains with fuel cell systems and an interchangeable rolling chassis for use in a range of light-duty vehicles, including commercial vans.

BONFIGLIOLI USA

Electric wheel, travel, track and drum drives plus complete electric powertrains for forklifts, access and aerial platforms, agricultural and forestry equipment, airport vehicles, concrete mixers, construction equipment, light road vehicles and material handling machines.

Hebron, Kentucky, USA

Web: www.bonfiglioli.com

News for Bonfiglioli USA

The company, which boasts more than 40 years of experience in electromobility, has developed a range of electric drive technology. Bonfiglioli USA recently electrified two new products for compact track loaders, medium excavators and large boom aerial work platforms.

The 606W3E series wheel drive was developed for medium to large boom lifts (80ft to 210ft). The 705C2E and 709C2E track drives have been engineered to withstand harsh operating environments faced by medium to large excavators and compact track loaders.

All solutions incorporate either ac induction or internal permanent magnet electric motors integrated into a planetary gearbox for an overall compact solution, based on application performances and required space claims for various construction equipment machine designs.

BORGWARNER INC.

High voltage coolant and air heaters, battery packs, chargers, electric drive modules, e-turbos and boosters, fuel cell air supplies and turbine generators.

Auburn Hills, Michigan, USA

Web: www.borgwarner.com

News for BorgWarner

Lithium-ion battery system provider Akasol AG became a majority-owned subsidiary of BorgWarner Inc. in June 2021. The acquisition was expected to further strengthen BorgWarner’s commercial vehicle and industrial electrification capabilities as well as position the company to capitalize on what it believes to be a fast-growing battery pack market. Akasol’s headquarters are in Darmstadt, Germany, and will be run independently.

This move supports BorgWarner’s Project Charging Forward, which it announced during its Investor Day in March 2021. The company said that the project represents an acceleration of its electrification strategy, which is expected to bring the company’s electric vehicle revenue from less than 3% of total revenues today to approximately 45% in 2030.

The plan comprises three pillars, namely profitably scaling electric light vehicles, expanding into electric commercial vehicles and optimizing the company’s combustion portfolio.

BOSCH REXROTH CORP.

Electric motors, inverters, gear systems and control software.

Charlotte, North Carolina, USA

Web: www.boschrexroth.com

BRIGGS & STRATTON

Modular 3.8 kWh, 5 kWh and 10 kWh lithium-Ion batteries.

Milwaukee, Wisconin, USA

Web: www.basco.com & www.vanguardpower.com

The Vanguard product line from Briggs & Stratton includes gasoline engines as well as lithium-Ion battery packs

The Vanguard product line from Briggs & Stratton includes gasoline engines as well as lithium-Ion battery packs

News for Briggs & Stratton

The company said MarIndustrial, and its division DAC Industrial Engines, will sell and service the full product line of Vanguard commercial lithium-ion battery packs in Canada. Marindustrial is an industrial and marine distributor whose head office is based at Montreal in Québec, Canada.

Supported by an engineering department, the company specializes in the distribution, value-added power unit solutions and service of industrial engines including Vanguard engines.

The addition of Vanguard battery packs will give industrial customers access to an electric power alternative for off-highway equipment.

Briggs & Stratton has partnered with Allen Engineering Corp. to power its new AW16-B battery-powered buggy with a Vanguard 48 V lithium-ion battery pack, which allows it to reach nine-hour run times.

The partnership developed from Vanguard’s existing relationship with Kraft Fluid Systems Inc., one of the first technology partners signed on as a distributor of Vanguard battery packs.

CATERPILLAR INC.

Production hybrid systems and concept hybrid and electric drive systems for construction and mining machinery and complete machines.

Peoria, Illinois, USA

Web: www.cat.com

News for Caterpillar

Caterpillar’s theme for the 2021 MinExpo event of “Together, we’re mining better,” will celebrate the company’s partnership with mines and the ways that it assists customers to mine efficiently, effectively, safely and sustainably.

Electric vehicles are part of the sustainability message. The company said it will show a Cat R1700 XE LHD (load-haul-dump) with 100% battery-electric propulsion. It has a 16.5 ton payload, 53,330lb lift, tilt breakout force and 11.2mph top speed.

The batteries stay on the machine for charging optimize runtime and improve safety. To fully charge the LHD in as little as 20 minutes, the company claim that the new portable Cat MEC500 mobile equipment charger is the first of its kind in the industry. It can be moved via towing, fork truck or the Cat R1700 XE plus will eliminate the need for regular battery handling and swapping.

The company signed an agreement in June 2021 with Nouveau Monde Graphite Inc. Caterpillar will develop, test and produce zero-emission machines by 2028 for the Matawinie graphite mining project in Québec, Canada.

CONCENTRIC AB

Lubricant, coolant and fuel pumps, hydraulic products encompassing gear pumps and power packs as well as pumps and other key technologies for electrical and hybrid powertrains.

Redditch, Worcestershire, England

Web: www.concentricab.com

Concentric’s electrohydraulic steering pump systems has been specified by an OEM for new battery electric delivery vehicles

Concentric’s electrohydraulic steering pump systems has been specified by an OEM for new battery electric delivery vehicles

News for Concentric

The company announced in June a long-term agreement with a global truck and bus OEM to supply electric coolant pumps for a heavy-duty electric truck.

Concentric currently supplies the customer with e-pumps for its hybrid and battery electric buses. This new supply agreement is expected to significantly increase e-pump volumes.

The electric coolant pump boasts a robust design that includes a wet rotor, eliminating the possibility of a dynamic seal failure, a long service life aided by liquid cooled electronics and dc brushless design along with integrated diagnostics and utilizing sensors for temperature and pressure.

Concentric stated that it will also support a North American OEM with its EHS (electrohydraulic steering system). The OEM is developing medium- and heavy-duty battery-electric trucks used in the last mile and return to base segments.

Concentric said that its EHS system has been designed, developed and tested over many years for use in a range of on- and off-road commercial vehicles. The EHS system has earned production nominations with established OEMs entering the electric vehicle market, who require e-pump expertise to replace their hydraulic steering pumps previously driven by a conventional engine.

COULOMB SOLUTIONS INC. (CSI)

Battery systems, battery integration, heavy-duty electric components including dc-dc converters, on-board chargers, battery chillers, power steering pumps, water pumps, heaters, 150 kW dc fast chargers and ac vehicle chargers, ethanol range-extenders and hydrogen-ethanol fuel cells.

Livermore, California, USA

News for CSI

The company is the North American distributor for CATL commercial vehicle battery systems. In addition to CATL’s commercial vehicle LFP (lithium iron phosphate) battery technologies (cycle life rated to 4,000 cycles), the company has launched additional LFP battery systems, including long-life (8,000 cycles) and super long-life (12,000 cycles) battery offerings.

CSI and CATL have revealed that they are partnering to launch a US facility for the production and assembly of commercial vehicle batteries by 2023.

CUMMINS

Electrified power technologies and products, including battery electric powertrain, fueling stations and MW scale energy storage, hydrogen fuel cells, PEM and alkaline hydrogen generators for industrial processes.

Columbus, Indiana, USA

Web: www.cummins.com

News for Cummins

The New Power Segment, which includes Cummins’ electrified power and hydrogen portfolios, represents the company’s investment in future technologies to deliver value and prosperity for its customers and communities using materials and technologies that have less impact on the planet. New Power has developed and acquired significant capabilities in electrified powertrains, battery design and assembly, battery management, fuel cell and hydrogen generation.

DANA INC.

Maumee, Ohio, USA

Web: www.dana.com & www.danatm4.com

Vehicle integration and engineering, hybrid-electric architectures for Class 8 vehicles, complete e-powertrain systems, complete e-axles, e-drive systems, e-gearboxes, e-hub drives, e-transmissions, electric motors, motor/inverter systems, inverters, on-engine generators and e-motion systems for work circuits, control systems, thermal management solutions including battery cooling plates and electronics cooling.

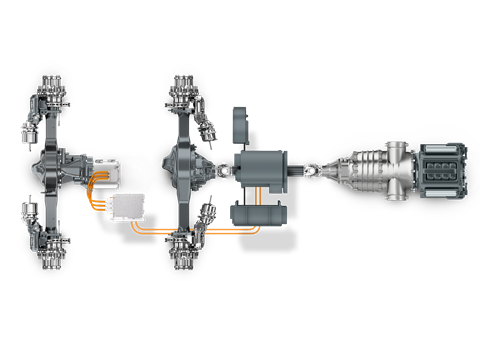

Dana Class 8 hybrid system Dana’s hybrid system for Class 8 trucks

Dana Class 8 hybrid system Dana’s hybrid system for Class 8 trucks

News for Dana

The company acquired Michigan-based Pi Innovo LLC in March 2021, an embedded software solutions and electronic control unit provider. The acquisition enables Dana to increase its in-house electrodynamics capabilities and electrification product portfolio by adding a library of turn-key electric vehicle application software, vehicle level controllers and auxiliary controllers.

Dana this year unveiled an expanded family of Dana TM4 SUMO HP electric motors and inverters, including the HV1000 and HV2500.

The TM4 SUMO family is designed for battery-electric, range-extended and fuel-cell vehicles. These high-performance motors and inverters are engineered to offer maximum flexibility, enabling direct-drive, series-hybrid or parallel-hybrid applications.

Seth Metzger, senior vice president of electrification at Dana, explained: “The demands of urban delivery trucks, city buses, long-haul trucks and other high-power on- and off-highway vehicles require electrified solutions that meet their demanding duty cycles.

“A compelling combination of compact design and heavy-duty power, the TM4 SUMO HP series is precisely engineered to address the requirements of Class 6 through 8 commercial vehicles.”

Reaching up to 800 V dc, the TM4 SUMO HP series offers up to 430 kW of continuous power and 540 kW of peak power, as well as a peak torque value of 2500 Nm.

The company stated that it is designed to match the efficiency map of an internal-combustion engine when used as a range extender, and can reduce operating costs by more than 35% when compared with a conventional diesel-powered vehicle.

Dana said that the series uses a motor with compact concentric winding technology to deliver maximum torque density, and leverages its internal permanent magnet technology for optimal efficiency and cost. TM4 SUMO HP technology has been combined with Dana’s field-proven axle designs to support e-Powertrains for heavy-duty vehicle applications.

DANFOSS EDITRON

Motors (permanent magnet synchronous technology or synchronous reluctance assisted-permanent magnet technology) with a power capability of between 30 kW to 6000 kW, converters, traction systems, fuel cell compressor systems designed for automotive, medium-duty and commercial bus applications for up to 150 kW fuel cell stacks.

Longmont, Colorado, USA

Web: www.danfoss.com

Sporting an historic brand and a retro design, the FNM 833 delivery truck is fully electric and uses a drivetrain system from Danfoss Editron

Sporting an historic brand and a retro design, the FNM 833 delivery truck is fully electric and uses a drivetrain system from Danfoss Editron

News for Danfoss Editron

The Danfoss Editron, Meritor and Electra Commercial Vehicles have formed a consortium called Electric Powertrain Integration for Heavy Commercial Vehicles (EPIC).

Through the EPIC partnership, the three members will design and develop an electric powertrain system. This will use a high-power electric motor and high-efficiency silicon carbide inverter delivered by Danfoss Editron and a three-speed transmission, geared differential and lightweight brakes provided by Meritor. Electra Commercial Vehicles will be responsible for the integration of the battery-electric chassis and to build four different chassis for validation.

Danfoss Editron said its motor will be based on a patented architecture and thermal management methodology and that only one motor will be required in the electric powertrain design, at a time when existing products need two motors to meet the product segment’s power requirements. Using one motor is seen as a step-change in the industry, as it will lead to a reduction in parts, weight and cost.

Danfoss Editron also stated that it is powering fully-electric trucks for one of Brazil’s largest fleets as Brewer Ambev has partnered with Brazilian EV specialist FNM.

FNM selected in late 2020 for Danfoss Editron’s drivetrain systems to power the FNM 833 electric truck. Pre-series vehicles are making deliveries in Rio de Janeiro, Brazil. Ambev has revealed that it expects to add 1,000 FNM fully electric trucks to its fleet.

Danfoss Editron also joined forces with the Ship and Ocean Industries R&D Center, a Taiwanese government institute, to launch the Green Energy Application Development Center in Taiwan. The new center will showcase a new electric marine dc power grid jointly developed by both companies as well as serve as a learning platform to marine professionals from the Asian-Pacific region.

DELTA-Q TECHNOLOGIES

Battery charging solutions.

Burnaby, British Colombia, Canada

Web: www.delta-q.com

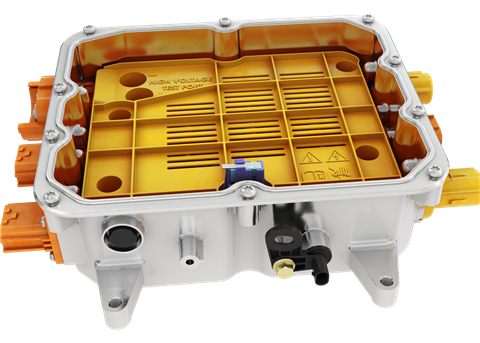

The compact Delta-Q XV3300 battery charger combines a 3.3 kW charger, dc-dc converter and charging station interface

The compact Delta-Q XV3300 battery charger combines a 3.3 kW charger, dc-dc converter and charging station interface

News for Delta-Q Technologies

The company introduced new battery charging solutions with the XV3300. Its compact design combines a 3.3 kW charger, 500 W dc-dc converter and an electric vehicle charging station interface.

Steve Blaine, co-CEO and executive vice president of engineering & quality for Delta-Q Technologies, explained, “The launch represents a significant product development milestone for Delta-Q.

“The XV3300 answers our OEM customers’ need for on-board charging power up to 20 kW delivered in a compact, fully sealed IP67 package.”

The 3.3 kW charger will be available in 58.8 V, 65 V, and 120 V models and is scalable, allowing OEMs to stack chargers for power levels up to 20 kW.

Delta-Q claimed that the XV3300 delivers a precise charge to battery packs of various chemistries and voltages to maximize battery life and optimize charge time,

The company’s new partner program, “Charged by Delta-Q,” was launched to provide battery and battery management system (BMS) manufacturers with the tools, brand association and access to pursue new opportunities with OEMs. It allows battery partners to combine marketing efforts with Delta-Q and offers global OEMs access to a curated network of battery and charging solutions.

Lloyd Gomm, vice president of business development for Delta-Q, enthused: “Delta-Q’s compatibility program is an exciting opportunity for us to build our brand, establish deeper trust with customers, and grow our business.

“By signifying our compatibility with our battery partners, we are able to expand our reach and showcase the true quality and reliability of our solutions to OEMs.”

The compatibility program was created to give OEMs confidence that the battery and charger combination will provide their electric products with best-in-class performance, prolonged battery life and maximum uptime. OEMs can view tested algorithms and integrations with Delta-Q’s chargers and variety of batteries through the program.

Battery partners receive a “Charged by Delta-Q” marking for their products, packaging and marketing materials. The logo signifies to OEMs that the battery or BMS was tested and validated with Delta-Q’s chargers and its engineers.

Rod Dayrit, director of business development North America at Delta-Q, said: “Since the intent is to bring value to current and potential customers looking for battery solutions compatible with Delta-Q chargers, we were selective in the battery manufacturers we invited to be part of this program.

“During our program launch, we have partnered with nine battery manufacturers that are aligned in bringing optimized and validated solution to the marketplace alongside Delta-Q. The program will invite other battery manufacturers in the future that align to the Delta-Q values, markets and vision in the same manner that the launch partners were selected.”

DEUTZ CORP.

Hybrid and all-electric drive systems for mobile off-highway equipment.

Norcross, Georgia, USA

News for Deutz

Throughout the pandemic year of 2020, Deutz AG said it continued to lay the foundation that will enable it to maintain its competitiveness and generate further growth over the long term.

The key building blocks of the corporate strategy are a technology-neutral approach in the development of the drive portfolio, including electrification and the use of alternative drive solutions.

EATON CORP.

Power electronics (inverters, dc-dc converters, on-board chargers), power distribution and protection (power distribution units, fuses, Breaktor circuit protection) and power systems (EV transmissions, 48 V solutions).

Southfield, Michigan, USA

Web: www.eaton.com

Eaton’s eMobility business secured a contract to supply power distribution units and Bussmann series fuses

Eaton’s eMobility business secured a contract to supply power distribution units and Bussmann series fuses

News for Eaton

The company said its eMobility business was awarded a contract to supply a 24 V to 12V dc-dc converter for use in a commercial heavy-duty battery electric vehicle (BEV) that will power accessories, such as antilock brakes and lights. The BEV will be sold in the North American and Chinese markets later this year.

Pratik Trivedi, general manager of Eaton’s eMobility business, said, “Dc-dc converters are an essential part of our eMobility product portfolio and are used in a variety of vehicle applications.

“Like traditional vehicles, electrified vehicles (EVs) have low-voltage loads on board-like infotainment systems, GPS and safety devices.

“So efficiently converting power from high to low is key, but it is also important to have a secondary converter to provide power to the traditional 12 V loads.”

Eaton’s specialty converter, also known as a battery equalizer, works in conjunction with another converter that takes power from the BEV’s 600 V system and steps it down to 24 V.

The component then takes it down to 12 V for use in low-voltage systems and to power a backup 12 V battery in case of a fault in the main power supply. Eaton stated that having this equalizer function, the 12 V battery and a split 24 V battery system, ensures essential safety equipment can operate on 12 V in the event of a power failure. The dc-dc converter also includes noise reduction and interference rejection so there is no interference between the unit and vehicle electronics.

Trivedi added, “The converter is rugged and robust, providing a seal against environmental factors such as salt spray and water, and has high vibration resiliency. It is an ideal solution for manufacturers that require a dependable method to power traditional vehicle components in high-power battery electric vehicles.”

The company announced in April 2021 that its eMobility business secured a contract to supply power distribution units (PDUs) and Bussmann series fuses to a global vehicle manufacturer for use in a new BEV light-duty commercial vehicle. The PDUs are scalable and can be applied to a wide range of future vehicles.

PDUs, also known as junction boxes or fuse boxes, connect the main battery power to the rest of the vehicle that is similar to how a service panel connects the main power source to each of the branch circuits in the house. While distributing power through the vehicle, PDUs deliver a safety function by providing circuit protection.

Eaton stated that it earned the supply agreement due to the unique features it was able to offer over competitors, including the complete integration of the Bussmann series fuses into the PDUs for protection of four auxiliary circuits.

The eMobility team leveraged its electrical expertise to design a functional and cost-effective product to meet the stringent circuit protection requirements of the vehicle. The PDUs also went through rigorous testing to ensure long-term reliability.

Kevin Calzada, global product strategy manager for power distribution and protection with Eaton eMobility, explained, “Fuse durability simulations are unique in the industry and help OEMs reduce risk.

“If not specified correctly, auxiliary fuses can have issues with nuisance trips. But with our experts leading the fuse coordination, we were able to demonstrate high long-term reliability with our fuse sizing analysis.”

The OEM also required the PDUs to offer multiple levels of safety. The PDUs allow access to the box to ensure safe repair and service. They also have a test port that allows for an electrical meter to be used as a probe to contact miniature circuit boards that signal if the unit is still charged, preventing the technician from contacting high voltage.

Eaton’s eMobility business was formed by combining products, expertise and global manufacturing capabilities from Eaton’s electrical and vehicle groups.

ENERSYS

Motive power batteries including thin plate pure lead (TPPL) and lithium-ion, Odyssey Absorbed Glass Mat (AGM) engine-cranking batteries, charging systems and power management tools.

Reading, Pennsylvania, USA

Web: www.enersys.com & www.odysseybattery.com

News for EnerSys

The company added NexSys iON lithium-ion batteries to its power solution portfolio in 2021. They are engineered with a nickel manganese cobalt (NMC) large format prismatic cell chemistry to deliver high-energy capacity in a small footprint.

With modular construction, the company said that the power system can maintain a high State of Charge (SOC) as a result of its speed of recharge capabilities and can be upsized or downsized as demands change.

Designed for heavy-duty applications, the virtually maintenance-free NexSys iON batteries have an integrated Battery Management System (BMS) that performs auto-diagnosis, voltage limitation (charge and discharge) and communication of performance data.

Utilizing a proprietary EnSite modeling software, EnerSys stated that it can work directly with the customer to right-size a NexSys iON battery and NexSys+ charger to their vehicle fleet.

FLASH BATTERY SRL

Lithium-ion batteries.

Reggio Emilia, Emilia-Romagna, Italy

Flash Battery offers a high degree of customization with its lithium-ion battery packs

Flash Battery offers a high degree of customization with its lithium-ion battery packs

News for Flash Battery

The company said that it has developed more than 450 different models of lithium-ion batteries since its start in 2012.

Flash Battery handles the entire process, from the preliminary consultancy to final testing, through meticulous conversations with customers to create fully customized products.

The battery packs are produced in small and medium quantities for customers around the world and are used in vehicles such as material handling, urban delivery, construction machinery, agricultural and airport ground support equipment.

The company has developed its own battery balancing system, or battery management system, which it calls the Flash Balancing System. It works with individual cells using active and passive balancing, and Flash Battery claimed with a current is at least 20 times higher than conventional lithium batteries.

The company commented that this translates into a 20-fold decrease in equalization time and maintains the balance of the cells, even when the battery is well into its life cycle.

The proprietary Flash Data Center remote monitoring system reports faults and determines the status of each battery at any time. The system protects batteries from unwanted abuse or technical anomalies. It also detects and eliminates false signals.

Flash Battery this year announced a partnership with Atech GmBH, a German drivetrain component distributor and system integrator. Atech can offer lithium battery packs as part of a complete solutions for developers of electric vehicles through the partnership.

In addition, the battery manufacturer has expanded and strengthened its partnerships with training institutes, research centers and universities (primarily the universities of Bologna, Modena, Parma and Reggio Emilia, Milan’s Polytechnic University and the Motorvehicle University of Emilia-Romagna in Italy).

The company stated that these collaborations are essential not only for developing new projects but also for identifying talent, primarily engineers who are at the heart of Flash Battery’s innovation processes.

FLUX POWER

Lithium-ion battery packs.

Vista, California, USA

Web: www.fluxpower.com

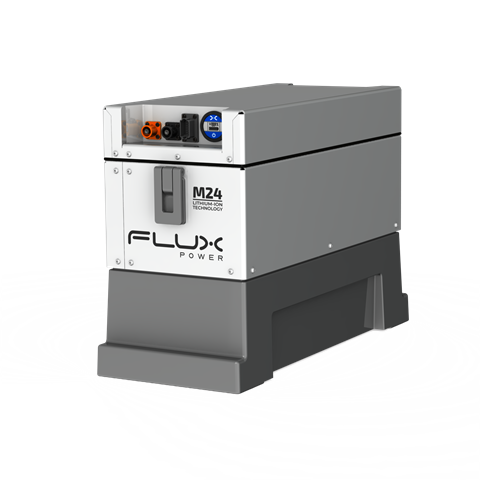

Flux Power’s M24 lithium-ion battery pack

Flux Power’s M24 lithium-ion battery pack

News for Flux Power

The company serves North American markets, including material handling equipment (forklifts), airport ground support equipment, stationary energy storage, robotics and other non-road machinery.

It designs, manufactures and sells battery packs in 24 V, 36 V, 48 V, 80 V configurations with various capacities depending on application. The company is also developing high-voltage products.

It launched the next generation of its M24 lithium-ion battery pack in April 2021. The original battery was introduced in 2019 and has evolved with customer input.

Designed to power end- and center-riders that are commonly used in warehouses and distribution centers, the M24 delivers 24 V, 420 Ah and is good for 3500 cycles. It is UL listed and compatible with forklift OEM interface requirements.

The new battery pack incorporates an improved SOC (State of Charge) gauge for accurate information about the battery pack, soft power-off function to ensure a smooth power transition for the equipment and a hinged top cover for service accessibility.

The M24 uses lithium-iron phosphate (LFP) chemistry and is available with Flux Power’s SkyBMS telematics solution.

FPT INDUSTRIAL

Hybrid power solutions, powertrains for on- and off-road vehicles, marine and power generation applications.

New Holland, Pennsylvania, USA

News for FPT Industrial

The company’s F28 Hybrid combines a 2.8 L diesel engine with an e-flywheel. The engine delivers a maximum power of 74 hp (55 kW), while the electric motor adds 26 hp (20 kW) of continuous power and has up to 30 40 hp (30 kW) peak power.

With Landi Renzo Group, FPT signed two Memoranda of Understanding (MOU) documents to explore the possibility of collaborating on clean fuel projects, focused on the possible development of natural gas and hydrogen technology respectively. The companies will explore potential collaborations on developing complete mobility solutions.

HATZ DIESEL OF NORTH AMERICA

Hybrid power solutions

Waukesha, Wisconsin, USA

News for Hatz Diesel of North America

The company has introduced the fiPMG (flywheel integrated permanent magnet generator) for use in hybrid systems. The design integrates a generator into the engine.

Hatz Diesel stated that the generator alone requires 90% less space and is 85% lighter compared to a conventional, mounted design. The fiPMG can be used in critical applications in hybrid systems, as a power outage backup or by providing a continuous power supply.

The fiPMG won an award in the “New Power Technology” category during the second annual Diesel Progress Summit & Awards in October 2020.

HONDA ENGINES

Electrified power units.

Alpharetta, Georgia, USA

Web: www.honda.com

News for Honda Engines

Honda Engines, a business unit of American Honda Motor Co. Inc. (AHM), launched the Honda eGX electrified power unit during the 2021 World of Concrete trade show.

It is the company’s first battery-powered motor designed to be incorporated into power equipment products for indoor and outdoor use.

Honda Engines said that it designed the motor for OEMs in the heavy-duty industry who want to provide battery-powered options to their customers, without investing in the engineering and funding required to develop their own motors.

The motor has a comparable shaft, mounting position and footprint as the Honda GX100 and GX120 gasoline engines.

HUMMINGBIRD ELECTRIC VEHICLES

All‐electric powertrain components and systems, charging stations and whole vehicles.

Livermore, California, USA

Web: www.HummingEV.com

IDEANOMICS

Facilitates adoption of electric vehicles by commercial fleet operators through vehicle procurement, finance and leasing as well as energy management solutions under its sales to financing to charging business model.

New York, New York, USA (mobility divison)

Web: www.ideanomics.com

Ideanomics WAVE’s wireless charging solutions can be embedded in roadways to charge vehicles during scheduled stops

Ideanomics WAVE’s wireless charging solutions can be embedded in roadways to charge vehicles during scheduled stops

News for Ideanomics

Brands under the Ideanomics Mobility umbrella:

- Solectrac Inc., which develops battery powered tractors for agriculture and utility operations.

The purchase of the tractor builder was completed in June and Ideanomics said it will support Solectrac across “various business functions, providing operational confidence to scale and become established as a global leader and supplier of clean agricultural equipment”; - US Hybrid specializes in the design and manufacturing of zero emission powertrain components for electric, hybrid and fuel cell medium- and heavy-duty municipality vehicles, commercial trucks, buses and specialty vehicles.

US Hybrid has developed and deployed electric, hybrid and fuel cell vehicles for decades. Established in 1999, the company has also designed, developed and manufactured electric powertrain and fuel cell engines for medium- and heavy-duty fuel cell commercial buses and truck OEMs, and; - Wireless Advanced Vehicle Electrification (WAVE) is a developer of inductive charging solutions for medium- and heavy-duty vehicles in the US.

The company, founded in 2011, can develop and integrate high-power charging systems onto heavy-duty electric vehicles.

JOHN DEERE POWER SYSTEMS (JDPS)

Hybrid, drivetrain and electronic solutions.

Waterloo, Iowa, USA

Web: www.deere.com

News for John Deere Power Systems (JDPS)

The company has continued its commitment to helping OEMs implement electrified system architectures. John Deere offers engine, drivetrain, and electronic solutions with hybrids that have been proven with more than two million operating hours.

Implementing alternative power systems such as drivetrain and electric solutions in off-highway equipment will depend on being able to optimize an overall power solution of balancing mechanical, hydraulic and electric power systems and cost.

John Deere stated that it can offer a broad range of expertise in mechanical and electronic solutions.

Matt Hoover, drivetrain & electrification product specialist at JDPS, said, “We are in an interesting and exciting time to move our industry forward as electrification is on the rise, and machines are becoming smarter and more connected.

“Control solutions are becoming more powerful and precise, which is an ideal landscape to introduce electrified solutions that are efficient and easy to operate.”

Evolving technologies mean customer needs can be addressed in new ways. Just as the company accomplished this with its 13.6L diesel engine, John Deere said that it has applied the same customer-first principles to electrification solutions.

The John Deere eAutoPowr Transmission is a continuously variable transmission with an electro-mechanical power split. The company claim that the drive is more efficient and wear-free compared to conventional CVTs, with another feature being the provision of up to 100 kW of electrical power for external consumption.

John Deere over the past 12 months introduced its Smart Industrial strategy, which is designed to unlock new value for customers while simultaneously revolutionizing the agriculture and construction industries through the introduction of new technologies.

LIEBHERR COMPONENTS

Components for combustion engines, including fuel injection systems and controls.

Nussbaumen, Aargau, Switzerland

Website: www.liebherr.com

Liebherr is developing alternative injection concepts with hydrogen and other alternative fuels

Liebherr is developing alternative injection concepts with hydrogen and other alternative fuels

News for Liebherr Components

The company said that it has developed “climate-friendly” injection solutions designed for use with hydrogen and synthetic fuels.

As the internal combustion engine is still the dominant form of mobile propulsion, Liebherr’s Components Divison said it sees it as a logical step to further develop the internal combustion engine and make it able to use CO2-neutral fuels.

Liebherr stated that it is currently working on solutions for direct hydrogen injection, which will be ready for series production to meet upcoming CO2 emissions targets.

Regarding synthetic fuels, Liebherr said that it is partnering with representatives from the energy supply industry, process engineering, vehicle and engine manufacturing and research and development fields. The focus is on testing methanol-based fuels that could be an attractive solution, especially for long distances and large transport volumes.

LITHION BATTERY

Lithium-ion batteries.

Calgary, Alberta, Canada

News for Lithion Battery

The company’s new 80,000 sq. ft manufacturing facility in Henderson, Nevada, USA, is expected to open in the summer. Lithion will use the plant to manufacture its Valence line of battery modules as well as battery cells.

It will initially produce cylindrical lithium-iron phosphate (LFP) cells in 18650 and 26650 form factors. The company said that domestically produced cells and battery modules will allow it to meet the demands of customers, it works closely with OEMs and end users to provide custom solutions for critical applications.

Lithion Battery acquired the Valence battery module manufacturing business from Lithium Werks B.V. in December 2020. The acquisition accelerated Lithion’s lithium-ion expansion strategy by providing a suite of battery modules and BMS technology to enhance its custom pack offerings.

LOOP ENERGY INC.

Burnaby, British Colombia, Canada

Web: www.loopenergy.com

Loop Energy’s 50 kW hydrogen fuel cell range extender

Loop Energy’s 50 kW hydrogen fuel cell range extender

News for Loop Energy

The business announced an order for the company’s S300 fuel cell module to Slovakia-based manufacturer Mobility & Innovation a.s. (M&I), to fuel the electric powertrain of its new zero-emission 8m transit bus made with laminate composite material.

This order is the first under the commercial agreement signed between the parties, which anticipates more than US$1.9 million in fuel cell shipments from Loop Energy over the next two-and-a-half years.

János Onódi, CEO and co-owner of M&I, explained, “This marks the start of a new era in Slovakian bus manufacturing.

“Combining our best-in-class lightweight composite body truck and our technology with Loop Energy, one of the best fuel cell platforms in the world, is a natural and exciting next step for us.”

Loop Energy shipped 10 eFlow fuel cell units to be integrated into fuel cell electric buses from Skywell New Energy Vehicles Group in Nanjing, China. This is Loop Energy’s largest ever shipment and is the second phase of a multi-year project to deploy a fleet of 300 fuel cell vehicles.

Skywell’s new 10.5 m long bus is equipped with a heavy-duty 50 kW fuel cell engine, which has a range of 450 km with eFlow technology.

The company also entered into agreements with Rheintal-Transporte in Germany to provide fuel cell modules and expertise for heavy-duty trucking applications, and Morello in Italy to provide modules for integration into hydrogen electric heavy-duty tractors for use inside industrial plants.

Loop entered a joint market development agreement in In North America with New Mexico’s BayoTech for the deployment of hydrogen vehicles and hydrogen fueling infrastructure. The two companies will collaborate on the development of market opportunities for vehicles manufactured by Loop Energy’s OEM customers in combination with on-site hydrogen generation infrastructure provided by BayoTech.

The initial scope is further centered around the vertical markets of materials handling, warehouse and port logistics, including drayage, transit and coach bus service, urban delivery services; and stationary power applications.

Loop Energy completed its US$100 Million IPO on the Toronto Stock Exchange during Q1 2021.

MAHLE

Fuel cell, e-mobility technology such as fuel cell air filtration, humidifiers and thermal management systems, fuel cell exhaust systems and controllers, low voltage drive systems and high voltage electric motors.

Farmington Hills, Michigan, USA

Web: www.mahle.com

News for Mahle

The business said it maintained company-wide research and development expenses at a high level of €644 million (US$786m) throughout 2020. Future-oriented areas account for more than 80% of group research and development expenditure, with the main focus on hydrogen and e-mobility.

The group developed two standardized air filter solutions for fuel cells in 2020. With a modular approach, Mahle said it will significantly reduce developmentMike times and costs, which will give fuel cell technology a boost toward large-scale production.

In e-mobility, its second key area of future activity, Mahle has been enabling the faster charging of the traction battery of hybrid and electric vehicles. A new high-performance condenser developed by the group is expected to make electric vehicles more suitable for the mass market.

The Mahle Aftermarket business unit uses the expertise from the production of original equipment in its product range and supplies trade and vehicle repair shops. Its product line includes rotating electric components such as alternators, motors and thermal management components plus starter motors.

Mahle Letrika offers manufacturers of electric vehicles and the repair shops that service them dc and ac motors, brushless permanent magnet motors, regulators and master control units, magnetic switches, displays and keypads.

MAYHEW PERFORMANCE LTD

Consultants for battery electric vehicles, mine operation and project delivery.

Web: www.mayhewperformance.com

News for Mayhew Performance Ltd

Mike and Nicole Mayhew have been busy since they founded Mayhew Performance in February 2020.

He said, “We founded this company to be agnostic in the B2B space and focus on battery electric vehicles, health, risk management and safety. Now we have major mining clients around the world.

“Everybody’s starting to line up in the battery electric vehicle space, and we are expanding and hiring new people.”

The company offers benchmarking and validation for its clients, particularly when it comes to the battery versus diesel debate. It also works with mobile equipment OEMs. While the company was born in the world of mining, they have been approached by warehouse and logistics fleet managers and suppliers.

MERITOR

Modular electric axles and complete electric drivetrain systems for Class 4 through 8 on- and off-highway vehicles.

Troy, Michigan, USA

Web: www.meritor.com

MOTIV POWER SYSTEMS

All-electric chassis for trucks, buses, specialty vehicle applications.

Foster City, California, USA

Web: www.motivps.com

Motiv Purolator has taken deliver of new electric delivery vehicles built on the Ford F-59 platform and electrified by Motiv Power Systems

Motiv Purolator has taken deliver of new electric delivery vehicles built on the Ford F-59 platform and electrified by Motiv Power Systems

News for Motiv Power Systems

The fifth generation of Motiv’s EPIC (Electric Power Intelligent Chassis) chassis incorporates BMW batteries as well as the latest release of Motiv’s AdaptEV software.

The software offers hill hold driver assist, two-hour high-speed charging using direct current fast charging, telematics and vehicle to grid (V2G) support capability. Software upgrades are available to fleets via over-the-air updates.

With deployments underway, Motiv said that it is scaling its manufacturing capabilities to meet growing demand.

The company also announced the appointment of Tim Krauskopf as its new CEO to replace Matt O’Leary, who is retiring. Krauskopf moved from his role as the global executive director at AREPA, an industrial equipment restoration company.

O’Leary, who will become executive chairman, held the role of Motiv’s CEO since February 2019 and positioned the company with major fleet customers. He enabled founder Jim Castelaz to transition to CTO and raised US$95 million in funding.

MUNRO & ASSOCIATES INC.

Engineering consulting firm for manufacturing industries such as heavy industrial machines and vehicles, oil and gas, automotive, aerospace, defense and marine.

Auburn Hills, Michigan, USA

Web: www.leandesign.com

News for Munro & Associates

The company, lead by founder Sandy Munro, seeks to play a pivotal role by uncovering the details of the electric vehicle industry through its teardown and reverse engineering studies, as well as through its design and manufacturing expertise.

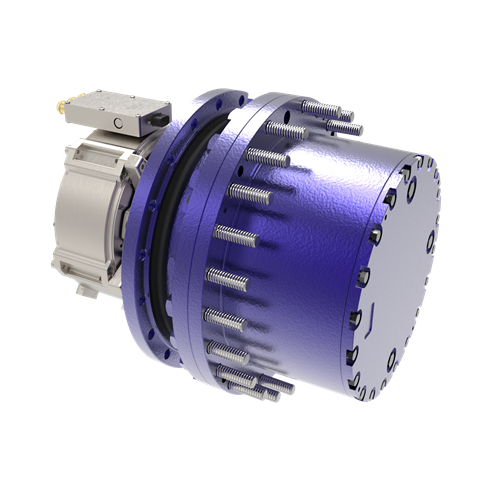

OMNI POWERTRAIN TECHNOLOGIES

Electrically driven planetary and parallel shaft gearboxes, permanent magnet axial flux motors and generators, IGBT and SiC MOSFET based motor control units and geared transmissions.

Houston, Texas, USA

Omni Powertrain Technologies’ Ve34/M27P8 combination electric drive

Omni Powertrain Technologies’ Ve34/M27P8 combination electric drive

News for Omni Powertrain Technologies

The company’s latest addition to its growing range of electric drives is the Ve34/M27 combination, which includes a double reduction planetary driven by a liquid-cooled axial flux permanent magnet motor produced by Omni’s Magelec Propulsion group.

It is offered as an alternative to hydrostatic drives for applications that require medium torque outputs. Potential applications include vehicles for specialized transport such as self-propelled transporters and mobile gantry cranes.

The Ve34/M27P8 combination electric drive includes a gearbox with maximum intermittent torque of 25,000 Nm and a gear ratio of 53:1 (others available) and maximum input speed of 3800 rpm. The electric motor has a maximum speed of 4500 rpm at 48 V and peak torque of 580 Nm.

OGURA INDUSTRIAL CORP.

Electromagnetic clutches and brakes, recirculation pumps and blowers for hydrogen fuel cells.

Somerset, New Jersey, USA

Web: www.ogura-clutch.com

Company news for Ogura

Battery-electric vehicles demand efficiency from all components, including clutches and brakes. Ogura said that its design engineers have focused on eliminating excess weight for mobile robotics and electrification projects.

Lower weight requires less power from the drivetrain and can improve response time for better overall performance. Weight associated with a brake can be reduced by eliminating parts and by removing unneeded material from a brake flange.

Ogura’s electromagnetic thin style holding brakes are designed to reduce the overall footprint of a motor brake package. Through internal improvements, the brakes are thinner and lighter but can produce similar torques of previous designs. Standard brakes are rated up to 50 Nm/37 lb-ft, and custom designs are possible.

On the clutch side, Ogura said its MA-7FSP general purpose clutch was used in a battery-electric cart designed to make strawberry picking more efficient. Torque from the electric motor was transmitted through a clutch on both sides, propelling the cart via a chain system.

PHILLIPS AND TEMRO INDUSTRIES (PTI)

Electric vehicle battery and cabin heating, electric APU systems and electric vehicle charging solutions.

Eden Prairie, Minnesota, USA

News for Phillips and Temro Industries (PTI)

Electric vehicle battery and cabin heating. Phillips and Temro (PTI) has expanded its electrification business to include a new line of high-voltage coolant heaters for electric vehicles operating in the medium- and heavy-duty, on- and off-road markets.

The EV heaters provide flexibility and customization when it comes to wattage, control and efficiency for a variety of applications. Customers can manage the exact temperature and control for a heating system with simple communications from the vehicle.

The safe and highly efficient resistive heating element allows for precise control to quickly warm and maintain the vehicle’s batteries or cabin temperatures. By leveraging the company’s 100 years of thermal and electrical component experience, PTI has produced more than 480,000 EV battery and cabin heaters for heavy-duty and automotive OEM customers since 2013.

Electric APU Systems: Idle Free provides innovative electric auxiliary power units (APUs) that deliver cab cooling for the heavy-duty truck market. The Idle Free Series 5000 eAPU mounts to the back of the cab and has both on and off-rail battery options allowing customers to keep valuable frame rail space.

Drivers benefit from more space inside with only a wall mounted evaporator and no interior ducting in the sleeper. Automatic start-stop technology is optional and provides uninterrupted comfort during long driver rest periods.

Electric vehicle charging solutions: EvoCharge, founded in 2009, represents one of North America’s original vehicle electrification providers and is a pioneer of home and commercial charging solutions.

The company provides reliable, safe and cost-effective charging stations as well as the EvoReel cable management system for single family, multi-family, workplace and other commercial spaces. EvoCharge products are fully compatible with all EV and plug-in hybrid electric vehicles sold in Canada and the US.

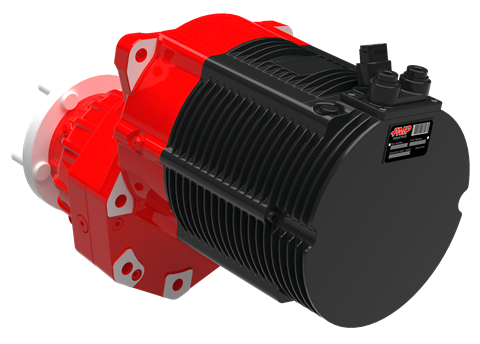

PMP INDUSTRIES INC.

Drives for electric vehicles, electric motors, integrated controllers, travel drives for wheeled applications, travel drives for tracked applications, integrated travel drives, swing drives for rotating systems, integrated swing drives for hydraulic excavators and variable displacement hydraulic motors.

Cincinnati, Ohio

The PMS625 drive from PMP is designed for electric vehicles

The PMS625 drive from PMP is designed for electric vehicles

News for PMP Industries

The company has been involved with electric traction systems since the 1990s, when it introduced the PMS product range for electric forklift and electric towing tractors.

The drive for integration and innovation has led to the introduction of high-speed integrated motors with speeds up to 10,000 rpm, reduced copper content and unrivalled sound performance, said PMP.

The compact packaging of the drives has paved the way for the introduction of PMP integrated controller drives, with robust components, integrated speed sensor and several new features optimized for off-highway mobile systems. The company claimed that this provides value in terms of reduced harnessing, compactness, ease of installation and serviceability,

PMP offers complete systems, combining its Electric Vehicle Driveline Divison electric motors with the gearing products of the Power Transmission Division.

SCANIA

Motive power including electric motors and machines.

San Antonio, Texas, USA

Website: www.scania.com

News for Scania

The company has been rebranded Scania Power Solutions to reflect the widening range of power options Scania offers and the capabilities of its marine, industrial and power generation engines range.

Scania said that the move comes at a key moment as it continues its journey toward electrification, where new types of motive power including electric motors and e-machines (electric motors plus their associated adjacent hardware) will come to the fore.

Scania has continued operational testing and development of its electrified power systems. The electric machine and power control unit draw on the company’s experience from electrifying its own on-road vehicles and will be modular and scalable with standard mechanical and system management interfaces.

SCHROEDER INDUSTRIES

Electric drive (E-Drive) filtration for use in electric hydraulic drive motor-pump units.

Leetsdale, Pennsylvania, USA

Website: www.schroederindustries.com

News for Schroeder Industries

As more organizations aim to be zero net carbon (ZNC), Schroeder Industries started a 2030 Initiative that aims to change the narrative of sustainability in the manufacturing industry (OEMs and MROs).

In addition to offerings from each of Schroeder’s product groups, the 2030 initiative started its focus on the core of its business with the Filter Elements product group.

Schroeder has a filter media for use in electric hydraulic drive motor-pump units through the introduction of the Electric Drive (E-Drive) filtration. These elements are characterized by an unusually low pressure drop, making them energy efficient and suitable for low energy consumption requirements compared to conventional hydraulic elements under the same ambient conditions.

The company said that its E-Drive media filtration technology guarantees safe and reliable equipment operation while conserving the use of energy.

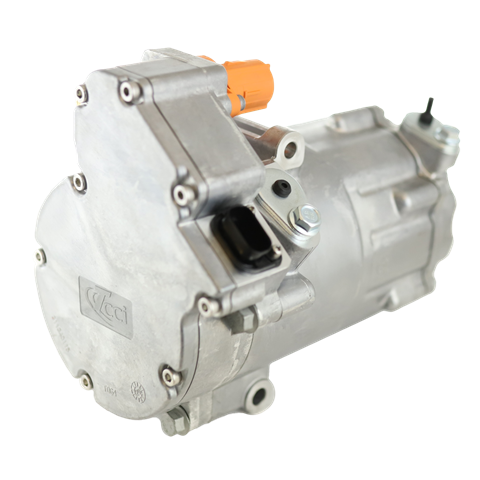

T/CCI MANUFACTURING

Electric and belt-driven compressors for heating and cooling batteries and cabs.

Decatur, Illinois, USA

Website: www.tccimfg.com

T/CCI’s large electric compressors are designed for battery cooling and air conditioning in the heavy-duty trucking, bus and railway sectors

T/CCI’s large electric compressors are designed for battery cooling and air conditioning in the heavy-duty trucking, bus and railway sectors

News for T/CCI Manufacturing

The company said its new Advanced Testing Center (ATC) in Decatur, Illinois, will help it develop and optimize customer systems. The center allows it to test heating, air conditioning and battery heating or cooling systems.

Dick Ennis, engineering director with T/CCI, said, “We have a very extensive suite of equipment in the ATC, including electric compressor durability test benches.”

The company introduced a range of new compressors in February 2021, which include high-voltage electric designs from 15cc/24V to 120cc/850V and 2 kW to 30 kW. The 400V to 850V products are designed for vehicles propelled by an electric motor including heavy-duty trucks, buses and transport refrigeration vehicles.

The 120cc/850V compressor is designed to provide battery cooling and air conditioning for heavy-duty truck, bus and rail. The 24V products cool the interior of a cabin when a vehicle’s engine is turned off and is available now. The larger 850V compressor is expected to hit the market this fall.

Ennis added, “We are investing a lot on electrification, and we already have a plethora of models developed and have some very robust new models under development.

“I think the preponderance of compressors within the next five to six years are going to be electric because the vehicles are going that way.”

T/CCI said that it was named a Diamond Supplier by Navistar International Corp. for the fourth consecutive year In June 2021, and that it was proud to support the truck and bus builder as it continued to “launch new products and make progress on ambitious endeavors, including plans for a full electrification solution that includes charging, route planning and infrastructure”.

TORQEEDO INC.

Electric and hybrid drives ranging from 0.5 to 100 kW for recreational and commercial vessels.

Crystal Lake, Illinois, USA

Web: www.torqeedo.com

News for Torqeedo Inc.

Part of the Deutz Group, Torqeedo celebrated its 15th anniversary and surpassed a milestone of 100,000 electric boats in 2020. New products included the Cruise 10.0 series of outboards and pod-drives with TorqLink electronic communications platform to connect all components of the propulsion system.

A fully electric steerable thruster was launched in March 2021 in collaboration with Poseidon Propulsion. It provides up to 65 kW of directional thrust and is powered by Torqeedo’s Deep Blue lithium-ion batteries with a capacity of 80 kWH to 1 MWh. The company said that installation is underway on solar-powered 14.65 m ferry, expected to start operation in August 2021.

Among the other marine fleets to install Torqeedo systems is Community Sailing New Orleans. Founded to introduce sailing to people of all ages, backgrounds and ability, the center opened in 2020. Its fleet includes Independence 20 recreational boats with Torqeedo Cruise fixed pod drives.

UNIQUE ELECTRIC SOLUTIONS (UES)

Electric and fuel cell electric vehicle propulsion systems.

Stony Brook, New York, USA

Web: www.uesmfg.com

UES’ first electric repowered package truck for UPS was deployed in New York City

UES’ first electric repowered package truck for UPS was deployed in New York City

News for UES

The company said that its engineered, end-to-end EV propulsion systems are deployed in new production vehicle platforms as well as mid- and high-volume conversions of on-road medium and heavy-duty trucks and buses. Applications include package delivery, passenger transportation and terminal trucks.

The uniqueEV platform, a Class 4 through 7 all-electric drive system available in full EV and a range-extended hybrid fuel-cell version, is field proven through daily service in UPS fleets in California and New York City.

VOLVO PENTA

Technology for renewable fuel, electric and hybrid industrial and marine applications.

Chesapeake, Virginia, USA (North America HQ)

Web: www.volvopenta.com

Volvo Penta acquired a majority stake in ZEM AS in June 2021

Volvo Penta acquired a majority stake in ZEM AS in June 2021

News for Volvo Penta

In line with accelerated sustainability ambitions, Volvo Penta is leveraging the Volvo Group’s experience in renewable fuels, electromobility and hydrogen fuel cells, as well as forming new collaborations for both the industrial and marine sectors.

The Volvo Group announced in 2020 its ambition to be a net zero emissions company by 2050 at the very latest. In order to be transparent on its progress, the company is now committing to the Science Based Targets initiative.

To support the Volvo Group’s sustainability goals, Volvo Penta has announced that it is to redirect further resources into accelerating its sustainability development, which is about reaching zero emissions – through fossil-free, renewable fuels, electric, hybrid technology – while continuing to provide innovative solutions to the industries it serves.

Volvo Penta and TICO, a North American provider of fleet services, terminal services and terminal tractor manufacturing, announced in March 2021 their ambitions to introduce an emission-free, electric terminal tractor.

During the past year Volvo Penta also supplied electric drivelines for three fully electric Rosenbauer fire trucks delivered to Amsterdam, Berlin and Dubai. With its electric driveline, Volvo Penta said that the fire truck boasts high loading volumes, compact dimensions and agility. The electric driveline also brings benefits such as zero exhaust emissions and significantly reduced noise levels.

In the marine segment Volvo Penta announced that it is becoming the majority shareholder of ZEM AS, a Norwegian marine battery and electric drive solutions supplier. ZEM is a company with 12 years of market experience as a supplier of marine battery systems and complete electric drivelines and a strong track record in Norway, one of the world’s most mature marine e-mobility markets.

Volvo Penta is powering two hybrid vessels using pilot technology in collaboration with Danfoss Editron. These vessels are a combination of integrated electric Volvo Penta Inboard Performance Systems (IPS), state-of-the-art gensets, and advanced vessel management systems.

WEBASTO GROUP

Battery packs and components, charging systems and thermal management solutions.

Fenton, Michigan, USA

Web: www.webasto-batteries.com

The Webasto eBTM2.0 is a stand-alone battery thermal management system

The Webasto eBTM2.0 is a stand-alone battery thermal management system

News for Webasto Group

The company said it is a supplier to Zeus Electric Chassis Inc., a Minnesota-based manufacturer of Class 3 through 8 electric work trucks.

Webasto will supply batteries for a 400 V-configuration work truck along with e-Battery Thermo Management System (eBTM) and Vehicle Interface Box (VIB) to manage the system.

The new eBTM2.0 is a stand-alone battery thermal management unit that ensures the optimal functioning of water-cooled battery packs used in electrical commercial vehicles and guarantees ideal battery cell performance over the long term.

VIB provides a single interface for communication between the battery system and the vehicle. This allows the customer to control up to 10 battery systems within one system. Furthermore, the VIB ensures an efficient electrical connection between the battery systems and allows you to connect auxiliary units.

Webasto said that it offers the best of both worlds with its standard CV battery system, the price and quality of a mass product and the accurate fit of a customized solution. Using a modular, scalable and geometric design the standard battery system is suitable for a wide range of vehicles.

The batteries have an IP67 rating, an explosion proof design with redundant venting system, and robust housings. The battery packs are tested to more than 3,000 cycles.

On the charging side of the business, Webasto’s PosiCharge DVS line of outdoor fast chargers is a stand-alone solution for small or remote fleets with heavier applications that can charge one or two vehicles.

XALT ENERGY

Lithium-ion energy storage technology.

Midland, Michigan, USA

Web: www.xaltenergy.com

News for Xalt Energy

When New Zealand’s first all-electric ferry leaves the dock in Wellington Harbor, it will do so thanks to lithium-ion batteries supplied by Freudenberg Sealing Technologies’ Xalt Energy. The batteries have been integrated into the ship’s design by McKay Group, a technology company focused on sustainable transportation solutions.

The 62ft 135-passenger composite catamaran ferry will be part of the East by West Wellington Harbor Ferry Service fleet and will make approximately nine daily trips. McKay Group installed 72 XMP 76P lithium-ion battery packs onboard that will supply approximately 550 kWh of energy.

XEROTECH

High voltage battery systems with pre-integrated onboard chargers, dc-dc converters and thermal systems.

Galway, Connacht, Ireland

Web: www.xerotech.com

Xerotech battery packs

Xerotech battery packs

News for Xerotech

The company recently launched its scalable and flexible Hibernium platform of lithium-iron battery systems.

Xerotech said this enables a large variety of battery packs from 10 kWh to 300 kWh in regular increments and up to MWh class systems that do not require bespoke engineering or design and development, offering OEMs the perfect battery for their particular machine regardless of annual production volumes.

Xerotech is also bringing several automotive-grade technologies to the off-road industry. The batteries have an advanced thermal management system that enables extremely high charge and discharge rates along with a specially engineered fire-retardant structural foam, which increases ruggedness and prevents thermal runaway propagation of battery cells.

Xerotech and Agder Gruppen announced in May 2021 the electrification of 200 mining and construction machines over the next five years using the Hibernium battery platform. Agder Gruppen is a supplier of heavy-duty rental equipment. The collaboration represents the battery supplier’s entry into the Scandinavian market as well as Agder’s strong move into battery-electric equipment.

Xerotech will also qualify one of its core proprietary battery safety technologies for space applications in conjunction with the European Space Agency (ESA). Xerotech utilizes its proprietary PPR (passive propagation resistant) technology, a critical safety requirement of future space missions, in its Hibernium product line for off-highway vehicles.

Xerotech is currently raising US$30 million to fund a fully automated serial-production line, which will come online in Q1 2022. It expects to have a full-rate production capacity of around 500 MWh of battery systems, which would be sufficient for around 7500 machines per year, by the end of 2022.

ZF

Electric drive components and off-highway systems for construction, agricultural, industrial and marine applications

Passau, Lower Bavaria, Germany

Web: www.zf.com

ZF’s electrified products in a compact wheel loader

ZF’s electrified products in a compact wheel loader

News for ZF

The company has expanded its range of electrified products for construction machinery. Under the eTRAC series ZF offers zero-emission solutions for compact equipment, mobile excavators and mid-sized wheel loaders.

The eTRAC eCD20-40 driveline system for compact vehicles incorporates a 48 V e-motor and transmission, which have been developed especially for this application using actual measurement data from conventional compact loaders, along with front and rear axles, inverters and an electric drive control unit.

Shortly after the start of the eTRAC volume production for compact loaders, ZF developed an electric drive system for wheeled excavators (eTRAC eCD50-90) and, in addition to its conventional axles, swing drive and hydrostatic powershift transmission, now also offers an electric central drive as well as an electrified swing drive system.

With e-mobility solutions (eCD115-210) for the next in size wheel loader class ZF further expands its central drive technology.

Thanks to its modular design the system can be used in various applications, like backhoe loader and forwarder, as well.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM