Parker Lord expands electrification solutions

07 December 2021

Parker Lord, a global supplier of thermal management encapsulants, adhesives and gap fillers, has expanded its portfolio of products for electric vehicle producers to include new thermally conductive (TC) adhesives and one-component (1K) low-density gap fillers.

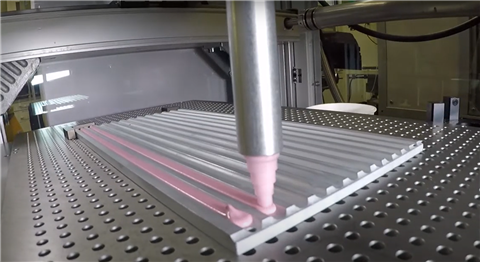

Parker Lord’s electrification product line now includes low-density gap fillers (shown) and thermally conductive adhesives.

Parker Lord’s electrification product line now includes low-density gap fillers (shown) and thermally conductive adhesives.

With the significant growth and development of battery pack technologies, EV manufacturers are placing an increased emphasis on pack design optimization. Manufacturers seek lighter weight, yet more compact solutions to gain additional energy density. At the same time, they are also striving for simplicity and affordability. To achieve these goals, manufacturers are looking at both immediate and long-term solutions including bonding individual cells directly to the cooling plate and even bonding directly to the vehicle chassis. For these designs to be viable, new bonding and thermal management technology is needed.

Parker Lolds’s newest commercially available material in its CoolTherm portfolio, is designed to meet these changing needs in the EV space. This portfolio includes a range of Cell-to-Pack (CTP) adhesive technologies, including a new TC urethane adhesive. Parker Lord said the materials are capable of delivering substantial thermal conductivity while also maintaining high levels of adhesion, enabling direct bonding of battery cells to cooling plates.

The CTP adhesives are designed to offer strong adhesion, substantial thermal conductivity, low density, flow characteristics and low dielectric constant – all of which are key to enabling battery and EV manufacturers in achieving higher pack energy densities and reduced manufacturing costs that new CTP battery designs offer.

The CoolTherm two-component (2K) portfolio provides customers with a variety of thermal conductivities and chemistries to choose from, which the company said provide high dispense rate, reliable cure performance and desired electrical properties. To complement the CoolTherm product line, where two-component mixing is not desired, a new non-silicone and environmentally friendly one-component (1K) gap filler has been developed. Parker Lord said the new 1K gap fillers help customers by reducing manufacturing and logistic complexity. Dispensable in any unit, the 1K solution is a low-density gap filler with excellent flow properties, the company said.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM