SuperTurbo, Linamar in manufacturing and supply deal

08 February 2022

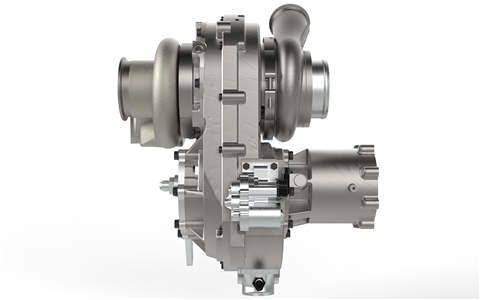

SuperTurbo Technologies Inc. and Canada’s Linamar Corp. have entered into an exclusive agreement aimed at bringing SuperTurbo’s turbocharging technology to the market. No financial details were provided.

The SuperTurbo is a mechanically driven turbocharger that controls engine airflow and exhaust gas recirculation (EGR), which the company said enables optimization of both performance and emissions at all operating points. Other benefits SuperTurbo cited include transient cycle efficiency, fuel cost savings, exhaust energy recovery through compounding, particulate reduction, cold start/low NOx improvement, engine downsizing, downspeeding and improved engine braking.

SuperTurbo and Linamar have announced a testing and manufacturing agreement involving the SuperTurbo turbocharger system.

SuperTurbo and Linamar have announced a testing and manufacturing agreement involving the SuperTurbo turbocharger system.

The SuperTurbo turbo technology is designed for on- and off-highway engines from 7.5 to 16 L displacement and can be configured to suit different engine architectures, the company said.

McLaren Engineering, a division of Linamar, will produce prototype units of the SuperTurbo for durability testing, which will be done at McLaren’s facilities in Detroit and at SuperTurbo in Loveland, Colo. The units will be tested on electric rigs and engine dynamometers for 12 months and upon successful completion of testing, Linamar will manufacture SuperTurbos for the global market.

“SuperTurbo’s partnership with Linamar brings our company one step closer to commercializing a technology that can significantly reduce emissions, increase engine performance and lower fuel costs relative to competing engine boosting technologies,” said Mark Herbst, CEO at SuperTurbo. “Linamar is a world-class manufacturing enterprise and an ideal partner for our company as it progresses into the critically important stage of delivering a commercial-ready product to market.”

Herbst added that Linamar’s McLaren facility in Detroit “specializes in new product introduction and low volume assembly.”

“They use many of the similar processes the high-volume Linamar factories use,” he added. “The assembly processes, controls, tooling, fixturing can be optimized at McLaren/Linamar and then transferred to a high-volume Linamar manufacturing facility when volumes dictate the need.

“The test specifications and processes were developed by AVL after an eight-month evaluation of the SuperTurbo taking into account the design, component specifications, warranty requirements and vehicle usage cycles.”

Linamar CEO Linda Hasenfratz said, “We are excited to partner with SuperTurbo to produce prototypes for durability testing of their revolutionary product that significantly reduces emissions of hydrogen, diesel and natural gas internal combustion engines while achieving higher levels of productivity and lowering total cost of ownership for the on-highway and off-highway commercial vehicle market.

“We consider SuperTurbo a leader in bringing this technology to market which will have a positive impact on our environment.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM