Training Academy On Heat Exchange

18 September 2020

Oesse introduced an online academy dedicated to heat exchange and its application areas, called Oesse Clips and available on the Blog section of the company’s website www.oesse.com. The clips are distributed also via Oesse’s YouTube channel and social media.

The academy consists of a series of appointments describing processes and technological solutions for Oesse’s heat exchangers and their application sectors. Corporate culture, Corporate Social Responsibility, organizational and process management projects are featured as well.

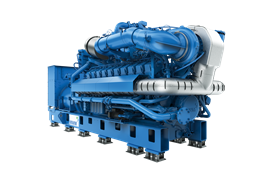

The first Oesse Clips have already been broadcasted and included: a three-part guide on heat exchange that describes the different types of coolers, the operating principles of a cross-flow heat exchanger, and how the compactness of a plates and bars technology and the brazing process improve the exchange efficiency and mechanical resistance; a presentation of Oesse HR.ange app, a digital collection of about 700 projects of cooling units for endothermic engines with performance data and technical drawings, selectable by engine, equipment and application; and a guide on how to develop a customized plug-&-play cooling module with just one part number containing all the components needed to connect the cooling system to the engine.

The next Clips topics will include lean techniques such as value added and non-value added (va/nva), a life-cycle assessment study on the environmental impact of a heat exchanger, air-oil coolers, and some specific solutions for the agricultural and forestry sector.

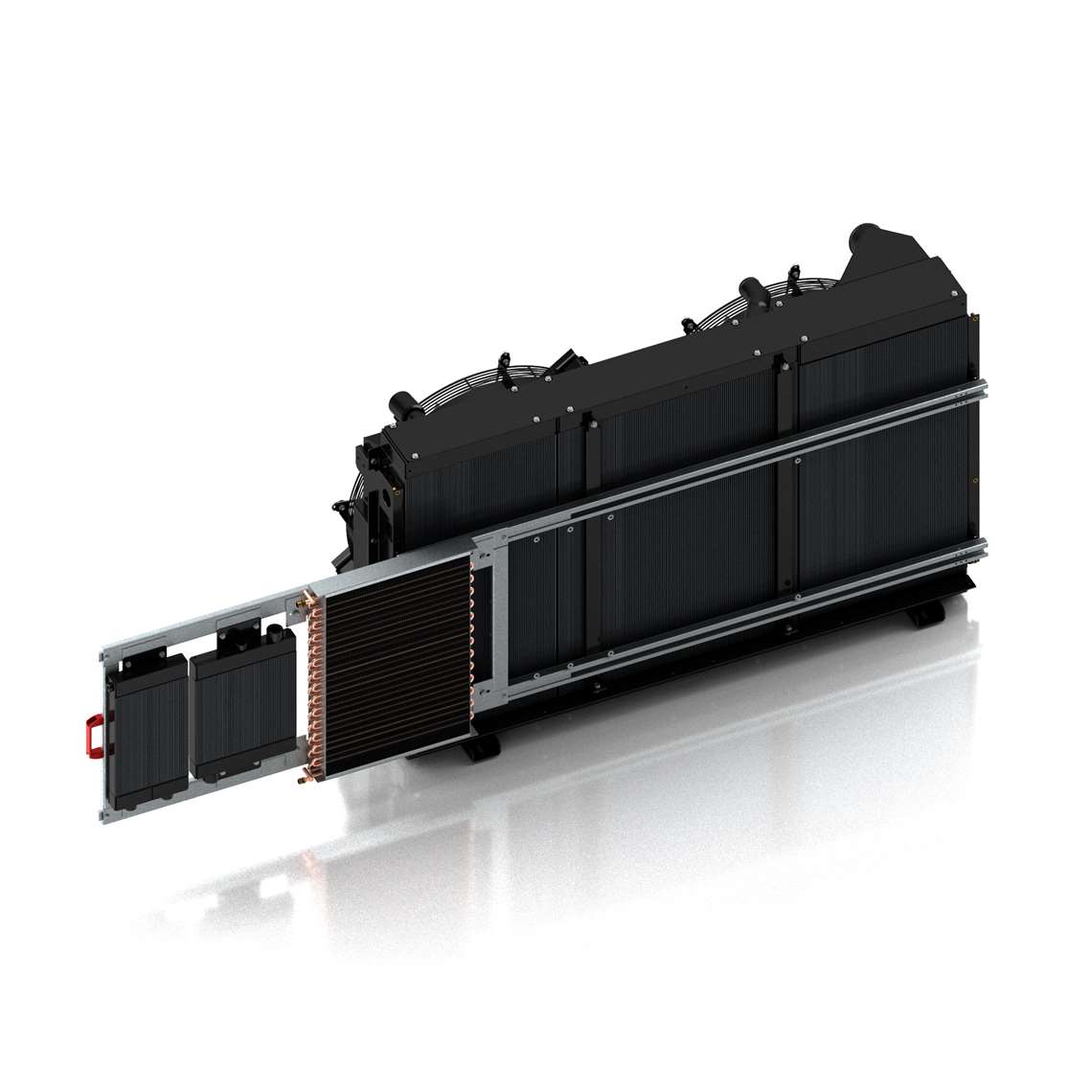

Regarding this last topic, Oesse recently developed a cooling unit for a 470-kW Caterpillar C18 engine in a forestry logging machine, where clogging and fouling of the cooling cores could compromise the performances of the cooling module.

The solution by Oesse allows periodic and easy cleaning between the radiant parts thanks to a sliding system on the radiator track. Besides the engine, the cooling module in the vehicle cools the hydraulic circuits and the radiator for air conditioning.

The hydraulic ventilation is controlled by a fan drive system that communicates with the engine electronics and allows, when possible, to hold the absorption of the two fans. It is also possible, again through the electronics, to periodically program a reversing of the fans to have an automatic cleaning of the exchangers.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM