Read this article in Français Deutsch Italiano Português Español

Transfluid strives to simplify hybrid conversions

22 February 2024

The HM hybrid transmission series is designed to fit between an internal combustion engine with a SAE standard flywheel and housing and transmission with a SAE input. (Photo: KHL Staff)

The HM hybrid transmission series is designed to fit between an internal combustion engine with a SAE standard flywheel and housing and transmission with a SAE input. (Photo: KHL Staff)

The variety of different driveline designs used in industrial and marine markets has historically presented challenges in converting from diesel-only to diesel-electric power. Transfluid, which specializes in industrial transmission equipment, set out to change that by developing a solution intended to simplify the process.

Already experienced in the production of power transmission and equipment and electric motors/generators, the company partnered with battery and motor controller manufacturers to develop the HM hybrid transmission series, a hybrid module offered in several versions that are designed to be “sandwiched” between an internal combustion engine with a SAE standard flywheel and housing and transmission with a SAE input. According to Transfluid, the result is a more standardized solution.

“We provide the hybrid module, the controller, the batteries, the battery management system – the whole nine yards to make it a hybrid vehicle,” said Chris Campbell, general manager, Transfluid. “If you’re a small manufacturer of machines that doesn’t have the resources to make a hybrid system, we can show you how to do that in a very short path.”

That path can be as little as six months using the company’s series of pre-developed, “pseudo custom-made” solutions.

Failsafe design

Many existing conversion systems have an electric machine (motor generator) on a splitter divider that mounts directly to the engine’s flywheel, Campbell noted. If the system fails, the vehicle or vessel is either “dead in its tracks” or you’re left with only engine capability.

With the HM transmission system, the input side serves as a hydraulic- or pneumatic-controlled clutch. Once disengaged, the engine is disconnected from the driveline, allowing the vehicle or vessel to be operated by the electric motor with zero emissions and minimal noise. If the engine is in use, the clutch is engaged and the electric motor becomes a generator that can recharge the batteries, if needed. This separation protects against unexpected system failures.

“If our electrical system would fail, you still have a diesel,” said Campbell. “If the diesel fails, you still have electric.”

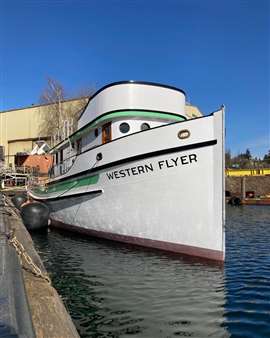

The HM transmission system was as part of the repowering of the Western Flyer, an iconic 77-ft. wooden boat immortalized in a John Steinbeck novel. (Photo: Transfluid)

The HM transmission system was as part of the repowering of the Western Flyer, an iconic 77-ft. wooden boat immortalized in a John Steinbeck novel. (Photo: Transfluid)

The engine and electric motor can also be operated at the same time to engage “booster” operation, which delivers extra torque to the driveline during acceleration. According to Transfluid, this can enable OEMs to more optimally size the internal combustion engine to the application.

Limited real estate required

The electric machine can be mounted in multiple positions to provide the optimal fit for the engine compartment, whether in newbuild vehicles and boats or for retrofit on existing equipment.

Limited “real estate” is required for installation, said Campbell. Only a short distance between the engine and transmission is needed – typically only a few hundred millimeters of space.

“We need to have the position from the flywheel housing face to the head of the hybrid transmission to install the hybrid module,” Campbell said. “Then we have to have room to install the batteries into the system, as well, because it’s part of the hybrid system. “

All operations are controlled by a proprietary electronic controller that communicates with the equipment through CAN Bus protocol, enabling a simple plug-and-play solution, Transfluid added.

Making history

Perhaps one of the more high-profile, and historic, applications of the HM transmission system was as part of the repowering of the Western Flyer, an iconic 77-ft. wooden boat built in 1937 and best known for being chartered by John Steinbeck for a 1940 research expedition to the Gulf of California, which he later chronicled in The Log from the Sea of Cortez.

The boat has recently been restored by the Western Flyer Foundation and recommissioned as a fisheries research vessel. Though the foundation originally hoped to convert the boat to full electric, it ultimately chose to go with a diesel-electric hybrid capable of being powered largely by diesel, but which can switch to electric mode for brief periods as needed for research purposes.

For the electric propulsion, twin 100-hp electric machines allow the Flyer to reach full speed in electric mode. (Photo: Transfluid)

For the electric propulsion, twin 100-hp electric machines allow the Flyer to reach full speed in electric mode. (Photo: Transfluid)

The system consists of a 425-hp John Deere 6135 turbocharged inline 6 diesel engine mated to a Transfluid HM3350 hybrid module provided and supported by drivetrain components distributor Palmer Johnson Power Systems. Palmer Johnson also provided the Twin Disc MGX516 marine transmission. For the electric propulsion, twin 100-hp electric machines allow the Flyer to reach full speed in electric mode and perform noise-free standby operations.

The HM3350 module also features three additional PTO heads to drive the steering pump as well as a clutchable pump to operate the research equipment. Head extensions for the PTO heads allow for a seamless integration with the Tier 4 diesel engine and marine gear. Transfluid has provided the propulsion control, CANBUS communication system and all components to make the complete hybrid supply. The operator is able to switch on the fly from diesel to electric mode with the press of a button, and engage or disengage the hydraulics from the control bridge.

For energy storage, 115-kWh lithium iron phosphate batteries provide autonomy in electric mode and power the house systems.

The boat, which was set for its maiden voyage the end of 2023, is also able to charge while underway in diesel mode using the power of the engine, or while docked using shore power.

Photo: Transfluid

Photo: Transfluid

A first for Croatia

In another historic move, Transfluid was selected to provide its HM hybrid transmission system for the first hybrid catamaran built in a Croatian shipyard. Commissioned by the Lokrum Public Reserve Authority in Dubrovnik, the 15-meter aluminum catamaran will transport up to 50 passengers across the Adriatic Sea between Trsteno and Lokrum.

The HM2000 hybrid propulsion system provided by Transfluid incorporates two 20-kW motors and two 100-Ah batteries that will enable quiet and ecofriendly navigation at speeds up to 18 knots. The dedicated traction battery bank and regeneration mode provide the ability to power onboard services during navigation with the thermal engine.

According to Transfluid, this advanced solution not only reduces atmospheric pollutants, it also contributes to improved energy efficient, reducing the catamaran’s overall environmental impact.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM