Vehicles’ Electrical Protection

02 February 2020

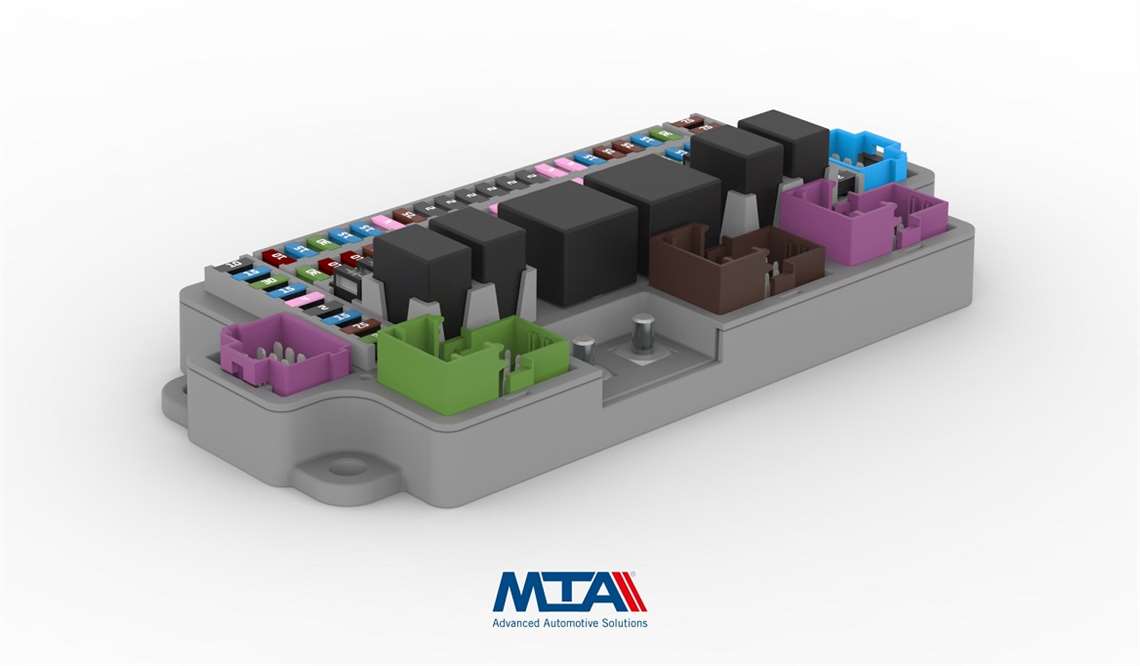

MTA will exhibit at ConExpo/CON-AGG the expansion of its range of electrical protection for off-highway application, which introduces units using printed circuit board (PCB) technology alongside the traditional wired products.

The MEC 97 unit with PCB is made with press-fit, a technology that MTA has chosen as an alternative to welding; the unit is designed for the engine compartment. For installation in the cabin, the new C-MEC 138 is designed and built with similar features to the MEC 97, that is press-fit technology and a high level of customization options. The C-MEC 138 unit is in charge to distribute power in the vehicle and protect the primary electrical services.

PCB technology allows to perform the same functions as with wired units but with the advantage of optimizing cables, facilitating assembly in production lines and direct supply to the OEMs for installation in the machine.

The new flexible design of the C-MEC 138 unit includes a base that always remains the same and a customizable mask with unconnected connectors. When the customer needs to change only the fuses, he will keep the mask, the connectors and the existing PCB. If the contents remain the same, but there is a need to change the scheme, the PCB alone will be changed with a very small investment and very short lead times. If both the PCB and the contents do not correspond to the customer’s needs, just the PCB and the mask can be redesigned. The changing of the mask, not having integrated connectors, will require a relatively simple mould reducing costs and time.

The C-MEC 138 is meant for new applications but also for customers that already use MTA’s five-way frame, with which it is perfectly interchangeable.

At ConExpo, MTA will also introduce to the North American market its Idea dashboard, a customizable cluster through MTA’s Studio proprietary software.

The Idea dashboard is specially designed for off-highway applications and can be used also as a display, available both in portrait and landscape versions. Idea is compact in size – 11.6 x 5.7 x 1.8 in (294 x 142 x 45.6 mm) – and complies with IP66 protection standard. The device can be powered with 12 or 24 V direct current.

Machine’s parameters are displayed on a 7-inch (178 mm) thin film transistor (TFT) glued to the front glass with optical bonding technique; a mineral glass cover with anti-fingerprint and anti-scratch surface also contributes to an excellent visibility in all conditions.

Among its other features, Idea includes one video input to connect an analog camera, a connector for BroadR-Reach Ethernet for a digital camera, and Bluetooth Low Energy to utilize specialized apps.

See MTA at ConExpo booth B-92809

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM