Vitesco unveils new e-motor with no permanent magnets

27 April 2023

EMR4 drive is suitable for passenger and light commercial applications (Photo: Vitesco Technologies)

EMR4 drive is suitable for passenger and light commercial applications (Photo: Vitesco Technologies)

Vitesco Technologies has unveiled a fourth-generation of its fully-integrated electric drive platform (EMR4, Electronics Motor Reducer) at the latest Vienna Motor Symposium.

The most noteworthy feature of the externally-excited synchronous machine (EESM) concerns the rotor, which does not incorporate permanent magnets. This means no rare earth metals have been used to produce the motor, sidestepping the carbon footprint associated with mining, processing and shipping of these materials.

Thomas Stierle, head of the Electrification Solutions division at the German Tier supplier, said: “Top results in the sustainability and efficiency of electric cars will be achieved, if the drive is optimally adjusted to the specific scenario.

“The externally excited rotor without permanent magnets is a particularly sustainable option for customers. The higher the performance requirements to the drive, the more economically attractive EESM technology becomes.”

Up to this point, most electrified vehicles have used a permanent magnet in the rotor. These permanent magnet synchronous motors (PSMs) are efficient and regarded as easier to manufacture than externally-excited units that use wound coils in the rotor to generate a magnetic field.

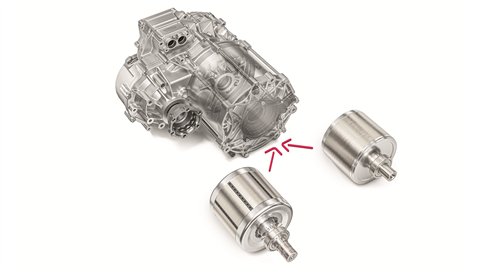

The EMR4 drive is a like-for-like replacement for permanent magnet units (Photo: Vitesco Technologies)

The EMR4 drive is a like-for-like replacement for permanent magnet units (Photo: Vitesco Technologies)

Vitesco states that by using a sophisticated winding principle it has managed to make the new EESM an ‘economically attractive option’. This is said to be particularly accurate when looking at high-performance applications that have previously required larger magnets; the EESM machines will be both more affordable and sustainable.

“Obviously, the EESM option requires an additional inverter module to control the coils,” said Dr. Gerd Rösel, head of Innovation for the Electrification Solutions division. He continued: “Nevertheless, we are really close to an EESM plug-and-play solution.”

In addition to eliminating the permanent magnets, with all the sustainability benefits, the machine offers other advantages.

“When the vehicle is sailing [coasting] efficiently, the externally excited machine saves a watt hour of electricity per kilometre because there is no drag from the permanent magnet field in the rotor,” explained Rösel. “This lowers the power requirement of the drive by up to 5% without the need for a mechanical decoupling device.”

According to material published by Vitesco, the EMR4 EESM is suitable for electric drives in passenger cars and light commercial vehicles.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM