WinGD Introduces Three Low-speed Engines

04 June 2019

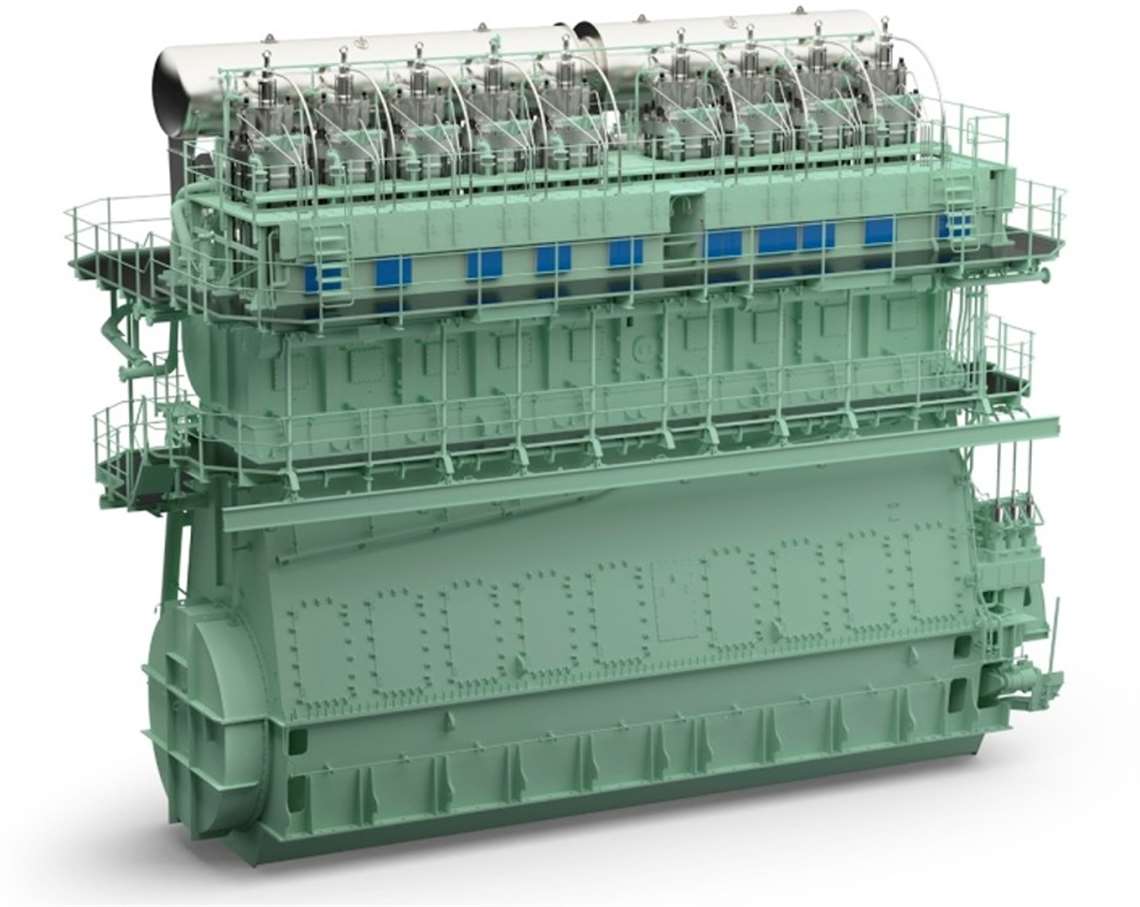

WinGD has introduced three new low-speed, two-stroke engines that are capable of operating on low emission fuels in response to what the company said is the growing demand for more efficient and reliable marine propulsion that serves the needs of an increasingly environmentally sustainable industry.

The new X40DF, X82D and X82DF engines are designed provide a wider variety of compliant choices to the ship owner, the company said

“Our industry is calling for greener-shipping and the success of our low-pressure dual-fuel X-DF portfolio is evidence that ship owners are looking for sustainability and efficiency from their propulsion system,” said Klaus Heim, CEO WinGD. “Growing our portfolio of engines ensures that ship owners have the right options to feel confident in their investment.”

The introduction was made at the Nor-Shipping trade show in Oslo, Norway.

X40DF Engine for Smaller Vessels

The new X40DF, in its standard configuration, is designed to run on liquefied natural gas (LNG) LNG, offering the first two-stroke dual-fuel engine for smaller vessels, the company said. As the engine is already compliant with all existing emission regulations, including IMO Tier 3, the entire support system is reduced due to the absence of the need for any exhaust-gas after-treatment system.

The X40DF, low-pressure, dual-fuel engine is available in 5 to 8 cylinder configuration, covering a power range from 2775 kW to 7480 kW, at 104 to 146 rpm.

X82-D Engine for Larger Vessels

For larger vessels WinGD’s new X82-D engine is dual fuel (DF) ready, with the ability to upgrade to operation with LNG, fulfilling requirements for gas-ready notations from Classification Societies.

The cylinder distance has been reduced to 1440 mm from 1505 mm, compared to the previous X82-B version in the WinGD portfolio. The brake specific fuel consumption (BSFC) has also been reduced depending of the rating point and the tuning variant chosen. The X82-D engine offers enhanced propulsion options within the VLCC, VLOC and Panamax container vessel segments.

Offered within WinGD’s Generation-X engine portfolio, the X82-D engine will be available from 6 to 9 cylinders, covering a power output from 16 560 kW at 58 rpm to 49 500 kW at 84 rpm. The engine has a bore and stroke of 820 X 3375 mm.

Key benefits of the X82-D include reduced engine length and weight, due to shorter cylinder distance with adapted bearing, and structural design for uncompromised reliability, the company said. The engine offers a wear resistant ICU MK-III with simpler overhaul concept and the WiCE (WinGD Integrated Control Electronics) engine control system with more functionalities supporting prolonged overhaul periods. All cylinder configurations are possible with a one-piece crankshaft design further reducing engine length and with pistons fitted with two piston rings for reduced friction losses. The X82-D has also been designed with optimized liner design to avoid cold-corrosion occurring within the cylinder.

Fuel savings amounting to US$1170 per day (2.6 ton/day consumption at assumed HFO cost of US$450 per ton) can be achieved for a VLCC running and X82-D engine at 90% engine power. This is achieved as a result of an increased firing pressure facilitating the significant fuel savings for vessels using the 7X82-D engine compared with its predecessor engine, the 7X82-B.

X82DF Dual-Fuel Engine

Allowing for the same enhanced propulsion options as the X82-D for larger vessels, the new X82DF is the latest offering in WinGD’s low-pressure X-DF dual-fuel engine portfolio. The engine dimensions are based on that of the X82-D diesel engine design but follows the Otto-cycle combustion principle in which gas and air are premixed at the right air-to-fuel ratio.

The X82DF engine has an integrated gas pressure regulation unit (iGPR), replacing the standalone GVU. The pre-chamber technology and the advanced design of the low-pressure gas admission valves offers a high level of combustion stability and reduced emissions. The X82DF NOX emissions produced are below that of the IMO Tier-3 level in gas mode without complex and costly exhaust gas after-treatment. As a result of the low amount of pilot fuel required (<0.5%) at 75% engine load, low particle and SOx emissions are also achieved. The engine has a bore and stroke of 820 X 3375 mm.

The low-pressure gas components of the engine allow for simple operation, maintenance and overhaul, and ensure maximum safety, as well as lower CAPEX and auxiliary power demand.

“Providing choices with the technology solutions that our customers need to take them confidently into the future means designing engines that are efficient, reliable, safe and compliant. Combined with our new, advanced engine control system, WiCE, the flexibility and responsiveness of our engines offers the control needed for optimizing a vessel’s efficiency,” said Dominik Schneiter, vice president, Research & Development at WinGD. “The uncertainty of the IMO’s Global Sulfur Cap 2020 caused a dip in new build orders early in 2018. However, vessel newbuilding order uptake is once again on the rise and the introduction of these engines further strengthens WinGD’s position in the market. As the marine industry’s leading low-speed gas engine developer, WinGD sees evidence that ship owners are ready to move forward.”

Since the launch of the X-DF engine series in 2013, the technology has proven reliable and efficient through over 230 000 running hours on 212 engines in operation and/or on order.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM