WinGD updates dual-fuel platform

17 February 2021

Methane slip reduction, improved combustion offered

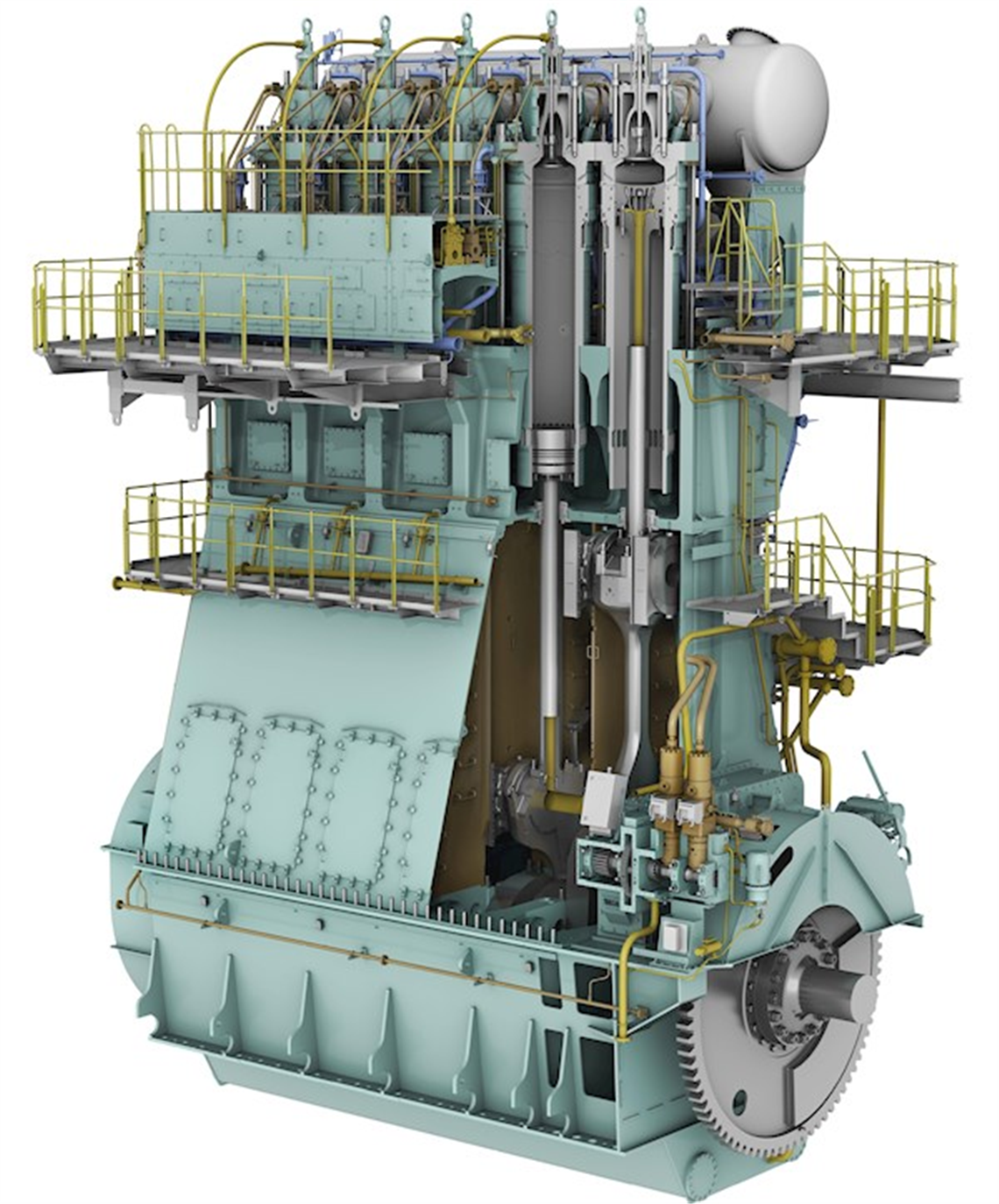

WinGD has updated its popular X72DF dual-fuel engine platform with an offer of four versions providing ship design flexibility while helping owners reduce installed power and emissions.

The X72DF is the best-selling engine in WinGD’s portfolio and accounted for every low-speed engine ordered for a newbuild LNG carrier in 2020. The X72DF is also applicable on Suezmax tankers, Panamax and sub-Panamax containers and Capesize bulk carriers.

“Our most successful engine model is now available in four configurations,” said WinGD Global Sales Director Volkmar Galke. “These options reflect the varied demands on shipowners to design vessels more efficiently, reduce installed power and cut emissions dramatically. Whatever route shipowners choose to meet these demands, there is now an X72DF that will work for them.”

Alongside baseline design improvements to the platform, an option is now available to optimize lower power output in five and six-cylinder configurations. These new versions are also available with enhanced methane slip reducing X-DF2.0 technology.

Demand for WinGD’s X72DF inspires launch of four new engine options, the company said.

Demand for WinGD’s X72DF inspires launch of four new engine options, the company said.

The base version, X72DF-1.1, incorporates the company’s new engine control architecture, WinGD Integrated Control Electronics (WiCE). Several design improvements, focused on enhancing reliability while simplifying production and installation, were made along with the addition of a modular scavenging concept to improve control over combustion and emissions.

For five and six-cylinder engines, further optimization is available to improve efficiency at lower power outputs. The X72DF-1.2 features a selected power/speed range with a lower specific fuel consumption. This configuration designed specifically for ships like the LNG carriers will be attractive to owners and shipyards seeking to limit installed power in line with the IMO’s energy-efficient design indexes for newbuilds and existing vessels.

The option of reduced power rating and limited cylinder configuration enables a more compact design, with a shorter thrust section, an optimized gear drive and a smaller fuel supply unit contributing to reduced engine length. This equates to greater flexibility in the engine room and versatility potential for the ship design.

The new versions are both available as X-DF2.0 upgrades featuring iCER (intelligent control by exhaust recycling) technology. Released in June last year, iCER reduces methane emissions by up to 50% compared with X-DF1.0 engines. The X72DF-2.1 and 2.2 have been specifically tailored for all LNG fueled vessels.

With improved overall GHG emissions, reduced methane slip and lower gas consumption, the X72DF-2.0s are the most competitive solutions in terms of opex and overall emissions for LNG carriers, Capesize bulkers, Suezmax tankers and 3,000-8,000 TEU container ships.

All four versions are available for order now. The first delivery is scheduled for April 2022, with delivery of the first iCER-equipped version targeted in the third quarter of that year.

X72DF-1.1 X72DF-1.2 X72DF-2.1 X72DF-2.2

No. of cylinders 5-8 5-6 5-7 5-6

Cylinder bore (mm) 720 720 720 720

Piston stroke (mm) 3086 3086 3086 3086

Speed (rpm) 69-89 69-79 69-89 69-79

MCR (kW) 25 800 15 600 22 575 15 600

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM