Fifty years of selling engines

20 May 2025

Conversations with distributors who sold the first Isuzu diesel engines in the U.S. a half century ago.

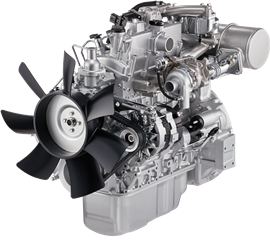

The Isuzu 4LE2X diesel engine is offered in a 66-hp constant speed rating option along with a 62-hp variable speed rating option. (Photo: Isuzu Motors)

The Isuzu 4LE2X diesel engine is offered in a 66-hp constant speed rating option along with a 62-hp variable speed rating option. (Photo: Isuzu Motors)

In 1983, an engine dealer in North Central Nebraska purchased several Isuzu 6BG1 diesel engines to run irrigation pumps for local farmers. The dealer’s region is home to the Sandhills, one of the least populated places and most diverse ecosystems in the world. It’s farm and ranch country. Agriculture there depends on irrigation, including gated pipe and center pivot methods.

Recently, one of those diesel engines retired after more than 70,000 hours of service. While regular maintenance played a role in the engine’s longevity – oil was changed every 300 hours – it pumped water for more than four decades even as it was exposed to everything Northern Nebraska’s weather could throw at it.

Irrigation power units

Dave Swanson was part of the company that is today’s Husker Power Products, and he sold the first Isuzu engines in the area. “I have sold various different brands of engines over the years,” said Swanson, who now runs Northern Plains Supply, an Isuzu Diesel engine dealer in Bassett, Neb. “The first irrigation power unit I sold was a Minneapolis-Moline engine in 1963, and since that time I noticed how many other brands of engines that were sold out of here for irrigation. It didn’t take long after we started selling Isuzu to figure out Isuzu engines were superior in a lot of respects. Especially because they were fuel efficient.”

Swanson credits engineering for the irrigation engine’s long working life, including chrome piston sleeves that helped avoid contamination and rust and a heat exchanger that used ground water rather an ambient air radiator. Reportedly, the only components that were replaced due to normal use were the water pump, starter and alternator.

Isuzu Diesel Midwest’s most recent Isuzu diesel engine application was this mobile dust collector from EnTech Industries. The Cyclone 20DC uses an Isuzu 4JJ1T Tier 4 Final diesel engine. (Photo: Isuzu Diesel Midwest)

Isuzu Diesel Midwest’s most recent Isuzu diesel engine application was this mobile dust collector from EnTech Industries. The Cyclone 20DC uses an Isuzu 4JJ1T Tier 4 Final diesel engine. (Photo: Isuzu Diesel Midwest)

“That’s a fact,” said Joe Vandeventer, account manager for Husker Power Products, when asked about the 70,000-hour Isuzu diesel irrigation engine, “and having one sit out in the middle of a cornfield for so long with only regular service is impressive. But it’s really not that unique for an Isuzu engine. In fact, I just got off the phone with a dealer out in California that has several generator engines, including an Isuzu 4BG1T, a 6BG1T and even a 4HK1 that are above 70,000 hours because they’re prime power generators. One of the engines is a 4BG1T that he said has over 120,000 hours.”

Joe’s father, Jon Vandeventer, purchased Husker Power Products in 1981. Originally located in the Sandhill town of Ainsworth, the engine distributor moved its headquarters to Hastings, Neb., in 1999.

“In the beginning, fuel economy was the biggest benefit to Isuzu engines,” said Jon Vandeventer, president and CEO of Husker Power Products. “It was so superior in fuel economy compared to the other companies. That was really what brought the engines to the forefront at that time, and then it turned out that they lasted longer than everybody else’s, too. That’s when the quality and the reliability came to the forefront. But it all started with fuel economy and basically up in the middle of nowhere in the Sandhills of Northern Nebraska.”

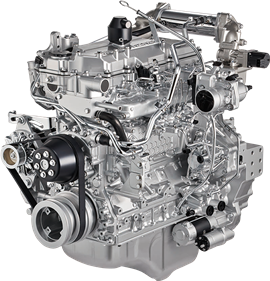

New 5.2 L 4H four-cylinder engine from Isuzu. (Photo: Isuzu Motors)

New 5.2 L 4H four-cylinder engine from Isuzu. (Photo: Isuzu Motors)

Half century of selling engines

When it comes to engines, milestones are measured in years as well as hours. It has been a half century since Isuzu diesel engines were first sold in the United States. Headquartered in Plymouth, Mich., today’s Isuzu Motors America LLC is the distributor of Isuzu diesel engines for off-road industrial applications in the U.S., Canada and Latin America. It is a subsidiary of Isuzu Motors Ltd., which has nearly 45,000 employees worldwide and designs and builds commercial trucks and buses as well as engines for industrial and passenger vehicle applications.

The company celebrated several anniversaries (based on five-year increments) of its distributors during a corporate meeting earlier this year.

These distributors were recognized for the time they have sold Isuzu engines: Isuzu Diesel Midwest, Fargo, N.D., 45 years; M&L Engine LLC, Schriever, La., 45 years; Husker Power Products, Hastings, Neb., 40 years; Hamilton Power Solutions, Vancouver, Wash., 40 years; Mack Boring & Parts Co., Somerset, N.J., 30 years; Westquip Diesel Sales, Edmonton, Alberta, Canada, 30 years; ADF Diesel, Ontario and Quebec, Canada, 20 years; United Engines LLC, Oklahoma City, Okla., 15 years; Valley Power Systems Inc. of California, 15 years; and Isuzu Diesel Mid Canada in Winnipeg, Manitoba, Canada, 5 years.

“Our distributors play a vital role in delivering Isuzu diesel solutions to customers across industries,” said Masaaki Sugino, executive vice president, Isuzu Motors America. “We deeply appreciate their dedication, expertise and commitment, and we are honored to formally recognize these milestone achievements.”

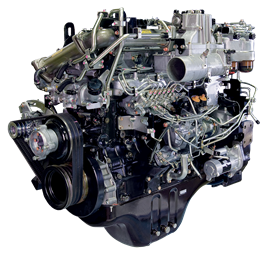

The 9.8 L Isuzu 6UZ1 diesel engine is offered in a 362 hp at 2,000 rpm variable speed rating. (Photo: Isuzu Motors)

The 9.8 L Isuzu 6UZ1 diesel engine is offered in a 362 hp at 2,000 rpm variable speed rating. (Photo: Isuzu Motors)

Expanding markets

“Our area of responsibility has expanded a lot since we started selling Isuzu engines,” said Jon Vandeventer. “Back when we first began, we just had a quarter of the state of Nebraska, which would basically be in the north central part. Today, our western edge is the Nevada-Utah border, the Dakotas to the north and out to Ohio, Kentucky and Tennessee to the east, and Kansas and Missouri to the south. We really focus on the middle of the country.

“When we started, we didn’t really work with any OEMs, and we wholesaled almost all of our engines to dealers. There were a good number of retail outlets that would sell directly to the end user, usually farmers, and we’d sell those engines quickly. As it went on, we picked up more and more dealers and everything was sold wholesale to these authorized Isuzu dealers. We didn’t really get into the OEM business until the late 1980s. When we started, our business was 100% going into irrigation. Now, it’s around 80% to a variety of OEMs and 20% to irrigation.”

Isuzu Diesel Midwest has also evolved as its market changed. When the distributor took on the Isuzu engine line, most of the powerplants were sold to run water pumps on farms and throughout the oil fields.

“The quality is unmatched as far as I’m concerned,” said Richard Springer, president and CEO of Isuzu Diesel Midwest, based in Fargo. “We see some engines just starting to come in for repairs now after 40 some years.”

In 1958, the Melroe brothers, who ran the Melroe Manufacturing Co. in Gwinner, N.D., built a compact self-propelled loader for a local turkey farmer and launched a new equipment category. The first Bobcat-branded skid-steer loader was introduced in 1962 and the brothers sold the enterprise in 1969. That success meant that by the 1980s Isuzu Diesel Midwest’s territory had become the unofficial capital of skid-steer engineering and manufacturing.

“A lot of people knew the Melroe brothers, and their success just kind of expanded into other people trying to build a better mousetrap,” said Springer.

Bill Springer, father of Isuzu Diesel Midwest’s Richard Springer, and one of the first power units the distributor built. (Photo: Isuzu Diesel Midwest)

Bill Springer, father of Isuzu Diesel Midwest’s Richard Springer, and one of the first power units the distributor built. (Photo: Isuzu Diesel Midwest)

Skid-steer expertise

Oakes Manufacturing came out with the Rounder skid steer while Hydra-Mac Inc. made units for ag and construction applications in a range of sizes. Both private labeled for other OEMs, as well. Mustang Manufacturing built its first skid steer in 1965, and there were many others throughout the region.

“We had 60% or 70% of the skid-steer market by the late 1980s,” said Springer. “We were supplying about two and a half containers a month, and there were 72 Isuzu engines in a container.”

Isuzu Diesel Midwest as well as Isuzu’s engineers worked closely with those OEM customers, bolting in engines when necessary or performing cooling tests and other tasks to help ensure a successful partnership.

“We sold engines to a company in Marcell, Minn., called ASV for a lot of years,” said Springer. “They built the Track Truck, and then they also built skid steers with tracks. We still talk with Gary Lemke, the original inventor. We had a very close relationship with him, as we do with all our OEMs. We’ve been selling Isuzu diesel engines to probably 70% of our OEMs for at least 30 years right now.”

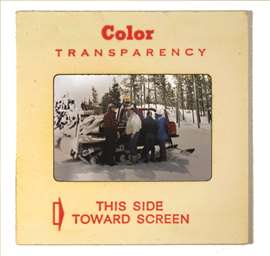

Isuzu Diesel Midwest was in West Yellowstone, Mont., when Isuzu engineers tested the ASV Track Truck in the ‘80s. (Photo: Isuzu Diesel Midwest)

Isuzu Diesel Midwest was in West Yellowstone, Mont., when Isuzu engineers tested the ASV Track Truck in the ‘80s. (Photo: Isuzu Diesel Midwest)

Isuzu Diesel Midwest was on hand with Isuzu engineers when ASV tested its new Track Truck in West Yellowstone, Mont., in the ‘80s. (Photo: Isuzu Diesel Midwest)

Isuzu Diesel Midwest was on hand with Isuzu engineers when ASV tested its new Track Truck in West Yellowstone, Mont., in the ‘80s. (Photo: Isuzu Diesel Midwest)

The trip to West Yellowstone

Founded in 1983, ASV’s first product, the Isuzu diesel-powered Track Truck, was an all-season, all-terrain truck with tracks in the back and balloon tires or skis in front. Popular for grooming snowmobile trails, the vehicle’s low ground pressure got customers asking for more.

ASV would go on to introduce a compact track loader prototype in 1988. After a couple of years of field testing, the Posi-Track MD-70 compact track loader hit the market with an Isuzu engine.

“We got a chance to go to West Yellowstone because ASV was doing some high-altitude testing with the 4JGB1-T engine,” said Joel C. Kuhl, who had just joined the distributor back then and today is vice president of Sales and Marketing for Isuzu Diesel Midwest. “Isuzu wanted to test it at 8,500 ft. So, we jumped in Dick’s Crown Victoria, and we headed out for West Yellowstone. It was during the time that companies did all of their photo shoots for snowmobiles. Isuzu had four engineers from Japan there and they all got in the Track Truck and they ran that thing hard. We changed the turbochargers and wastegates on the engine to see where the manifold pressures were. It was really something to watch the engineers really test that unit. That was the first time I ever got to see an engine really being tested like that. Because it was an automotive engine that they had industrialized, Isuzu wanted to make sure it was going to work.”

“Joel and I’ve had some really fun times with all the OEMs,” said Springer, “because lots of times we’d go visit them and we’d have to do some testing, and they’re like, ‘Well, go ahead, run the machine and do what you want to do.’ We got lots of hours running machines doing testing.”

“There is a lot of memories there,” said Kuhl.

Isuzu Diesel Midwest’s customer base has expanded into flameless heaters, generators, aerial lifts, dust collectors, construction equipment and many other products. Around 95% of the Isuzu engines the company sells today go to OEMs in a territory that includes North Dakota, South Dakota, Minnesota, Iowa and part of Wisconsin.

The distributor’s Winnipeg, Manitoba, Canada, location has an Oakes machine on the payroll to this day.

“We had just got an Isuzu engine installed in it and we were going through testing and then Oakes went through bankruptcy, so we ended up with it,” said Kuhl. “It’s literally the last one they ever produced.”

Stainless steel dreams

The parent company of Michigan-based Isuzu Motors traces its history back to 1916 in Japan when two industrial companies merged to build automobiles. Trucks powered by its own gasoline engines followed, and then it introduced its first diesel engine in 1933.

The engines had been proven in the company’s own products long before they reached the pages of Diesel Progress. The Tochigi Plant, home to the company’s engine production in Japan, opened in 1972. The editors covered the start of North American industrial engine sales in 1975, as well as the diesel-powered Isuzu automobiles and pickups it began importing in the early 1980s.

Springer got into the engine world in 1975 when he joined his father’s distribution business. “The person that set my father up was John Z. DeLorean. At that time, he came to Fargo, and they signed a contract with what was then called DeLorean Diesel. Then Ray Prussing got involved. So, I’ve met John DeLorean and I spent a lot of time with Ray Prussing Sr. and then in later years it was Ray Prussing Jr. who I dealt with a lot.”

DeLorean famously left a career with General Motors in 1973 and for a brief time worked with former GM executive Ray Prussing, doing business as DeLorean Diesel Corp. In 1975, the company secured the right to import Isuzu Diesel engines for non-automotive applications. DeLorean didn’t stick around for long, however, as he was focused on building his eponymous stainless-steel bodied mid-engined sports car. Karl Story, a successful Oldsmobile car dealer in Lansing, Mich., then bought DeLorean’s shares in the engine importer. Under Prussing and Story, the company dropped the carmaker’s last name in favor of Isuzu.

Then, “in September 1985, Isuzu Diesel became a wholly owned subsidiary of Isuzu Motors Ltd., and Toshio Tanaka was named the company’s president,” wrote the Diesel Progress editors in the June 1986 Engine Yearbook issue.

“We’ve had such a long-term partnership between Isuzu and Isuzu Diesel Midwest, it’s almost like family in a way,” said Kuhl. “Japan has always been supportive, and now we’ve got Isuzu Motors America near Detroit with their own huge engineering and service staff. They support us really, really well.”

Today, Isuzu engines power applications in agricultural, construction, industrial, medical and rental markets. On farms, the four-cylinder, 2.2 L water-cooled 4LE2 diesel engine has provided power to large irrigation systems for decades. The construction equipment market uses engines such as the six-cylinder 9.8 L 6UZ1 rated 362 hp to help reduce downtime and emissions. The company’s industrial engines also run critical and non-critical standby power generation sets with lower maintenance and limited warranties on engines up to 5 years/5,000 hours. Isuzu Motors said the rental market also benefits from its Isuzu REDTech Tier 4 Final products, offering customers power solutions through its distributor and dealer network, in addition to troubleshooting diagnostic tools and hands-on training related to general maintenance for customer support.

Isuzu Diesel Midwest fitted an Isuzu diesel engine to this large Concord air seeder made in North Dakota. (Photo: Isuzu Diesel Midwest)

Isuzu Diesel Midwest fitted an Isuzu diesel engine to this large Concord air seeder made in North Dakota. (Photo: Isuzu Diesel Midwest)

Bor-Mor Inc. built Isuzu-powered directional drills in Hugo, Minn. Case Corp. acquired the company in 1997. (Photo: Isuzu Diesel Midwest)

Bor-Mor Inc. built Isuzu-powered directional drills in Hugo, Minn. Case Corp. acquired the company in 1997. (Photo: Isuzu Diesel Midwest)

Changing landscape

The internal combustion engine market in general has evolved as it worked to meet the needs of end users and equipment manufacturers, as well as meet national and regional regulations. Husker Power Products and Isuzu Diesel Midwest expect that to continue even as some equipment makers adopt batteries.

“A lot of the manufacturers understand there’s going to be a place for diesel engines for the next 30 years at least,” said Kuhl, “but I think a lot of them are still looking at that industry because in metropolitan areas, they’re demanding electrification. Out in the rural areas where our territory is, it’s still all diesel.”

“In some cases, the electrification of certain pieces of equipment has brought us business,” said Joe Vandeventer. “The applications require charging of the batteries, but unless you’re next to a utility how does that get done? Well, it gets done with the diesel-powered generator. And building gen-sets for those applications has actually spurred a fair amount of business for us. It’s now a market that we’re focusing on.

“Take agricultural autonomous vehicles, for example. They are electrically powered because it makes sense with their autonomous drive systems. But they all have onboard power that needs to be supplied via a generator, and that has massive potential for us. And it’s a brand-new market that has a lot of room to grow. Battery-powered aerial drones are being used in the spraying of herbicide and fertilizer and that’s becoming an exploding market, too. Obviously, that equipment is used in remote areas in large fields and they need power. It’s a whole new market for diesel engines.”

Crossing generations

“The biggest things that we’ve always stressed about Isuzu engines comes down to quality and reliability,” said Joe Vandeventer. “Brand loyalty to Isuzu is pretty good because once guys have them in the field, they normally stick with [them] and that’s based on experience when they’ve had it for 70,000 hours or 100,000 hours.

“My dad started 40 years ago and started selling engines into the irrigation market. We’re still working on some of those engines, and they’re still out in the fields watering crops. That’s the best endorsement that I can give. The engines have crossed generations.”

This article originally appeared in the May 2025 issue of Power Progress.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM