Read this article in Français Deutsch Italiano Português Español

J-Squared facilitates machine learning without the cloud

11 February 2025

Embedded computers, systems enable artificial intelligence at the edge

FALC is the company’s latest line of small form factor computers. They include video processing and generative AI capabilities for making decisions at the edge. (Photo: J-Squared Technologies)

FALC is the company’s latest line of small form factor computers. They include video processing and generative AI capabilities for making decisions at the edge. (Photo: J-Squared Technologies)

Artificial intelligence has worked its way into many markets over the past decade, and now generative AI has ushered in a new era of innovation. By utilizing massive amounts of data and a complex set of algorithms, it can simulate the way a human brain learns and makes decisions. While there is a lot of noise around generative AI use cases, such as creating high school term papers and real estate listings, AI can also be used to control machinery used in agriculture, construction, mining and other markets.

Those applications can add another layer of complexity when it comes to implementing the technology. For example, because an autonomous haul truck must react instantly to millions of data points – such as geopositioning in the pit, weather conditions and high-resolution cameras that watch for obstacles or errant boulders that fall out of the bed – the connectivity requirements are such that cloud computing may not be reliable enough – if it’s even available.

“Cloud-based AI applications that require extensive data center computing have dominated until now,” said Jeff Gibson, CEO, J-Squared Technologies Inc. “The next phase of AI is at the edge where cost, data privacy and connectivity advantages can be realized.’”

The TRAX computer dates back to the original Octagon Systems product line that J-Squared acquired several years ago. It has been expanded in terms of products and applications. (Photo: J-Squared Technologies)

The TRAX computer dates back to the original Octagon Systems product line that J-Squared acquired several years ago. It has been expanded in terms of products and applications. (Photo: J-Squared Technologies)

Octagon Systems

Founded in 1990, J-Squared Technologies is a supplier of embedded computers, systems and services for mission-critical applications. It began as a manufacturer representative for semiconductors and then made small form factor computers. Based in Kanata, Ontario, Canada, the company has expanded its capabilities and its footprint. It now owns ESL Labs, an environmental testing laboratory in Dartmouth, Nova Scotia, Canada. It also added a maintenance, repair and overhaul (MRO) division with locations in Mississauga, Ontario, and near Atlanta, Ga., to support its computers and third-party products.

In 2018, it acquired Octagon Systems, which at the time was a Colorado-based supplier of rugged embedded computers used in mining, rail and transportation applications. J-Squared retained Octagon’s brand and added its products to its own catalog. Since then, it has expanded Octagon’s reach as well as its product line to include rackmount servers, the cabinets they mount in, displays, networking solutions and edge AI systems.

“In a typical commercial environment with good internet connectivity, many solutions allow you send all of that data back to the cloud for processing,” said Andrew Woollard, President, J-Squared Technologies. “But in the industries that we’re working in, you can’t rely on that connection. In mining and the military, for example, the processing has to be done at the site.

“If AI is going to be deployable in our markets, it’s going to require local processing. There’s lots of reasons for that: connectivity, reliability, real-time decision making, cost – that’s a big one – and privacy.

“We believe that more than 75% of the data in the next 10 years is going to be generated at the edge. That’s where you’re going to generate the videos and other data, so it makes sense to process it as close to the generation point as possible.”

With the goal of supplying a complete system, J-Squared also offers touch displays in 8 in. and 15 in. sizes. (Photo: J-Squared Technologies)

With the goal of supplying a complete system, J-Squared also offers touch displays in 8 in. and 15 in. sizes. (Photo: J-Squared Technologies)

Product catalog expands

The company expanded its Octagon hardware offering in 2022 with a family of small form factor computers called FALC, which include video processing and dedicated AI computing for making decisions on-site.

Available in three models, the FALC systems have GPU/AI accelerator capabilities and are designed for applications where connectivity to other devices, sensors and equipment is critical. The company offers wired and wireless connectivity options to ensure each computer is ready for Internet of Things (IoT) and vehicle-to-everything (V2X) functionality. They have IP ratings to withstand dust, sand and water. Because increased compute functionality generates a higher thermal output, FALC computers use conduction and convection cooling, including external IP-rated fans if the application allows.

The FALC computer family is related to TRAX, a line of small form factor computers that dates to the original Octagon Systems. Today, the J-Squared line is comprised of 10 different computers with wireless connectivity options, providing a platform for sensor, vehicle and equipment connectivity. It is also ready for IoT and V2X.

“FALC is a TRAX computer, but the difference is that it accommodates video processing and AI at the edge,” said Gibson. “We’re focused on achieving high-performance per watt at the edge. You get the TRAX functionality along with AI compute, video processing and sensor fusion. This enables deployment of AI applications at the edge.”

Achieving a higher level of performance per watt is no small feat. “While improvements to hardware have helped reduced the power consumption of devices, as applications become more complex and you’re processing more at the edge, software needs are going up,” said Woollard. “Before this trend of AI solutions, hardware and software were becoming more efficient. Now devices are going back to being power hungry.”

A typical application for a TRAX computer could be a large bulldozer used in a surface mine. “That application will have serious shock and vibration issues, so we have to build the computer properly to withstand that environment. There may be 30 or 40 sensors on that bulldozer, and all of that information feeds back into the computer,” said Gibson. “The mines are all about maintenance management of their capital equipment, and they have long wanted to detect problems before they lead to something like an engine failure. Today, in that bulldozer example, you will also have cameras, and you’ll have to feed that into the computer so you can process all of that data, too. That’s why GPUs and dedicated AI accelerators now must be designed and integrated into the hardware system.”

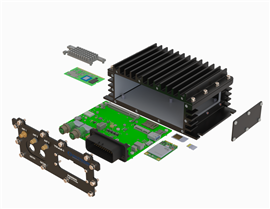

Here’s an exploded view of J-Squared’s TRAX computer. (Illustration: J-Squared Technologies)

Here’s an exploded view of J-Squared’s TRAX computer. (Illustration: J-Squared Technologies)

AI tech accelerator

Technology moves quickly, and with generative AI in the mix, the pace is expected to accelerate. The learning curve is substantial.

“There are different maturity levels out there, for sure. I think everybody, every one of our customers, knows they need to start leveraging AI,” said Woollard. “Some are further down that path and others already have a solution in mind and they’re trying to productionize it. Others are testing ideas, proof-of-concept wise. They can’t afford not to, really.”

“When those customers call on us, they know what they want to achieve with the technology,” said Gibson. “They might not understand all the dynamics of the technology, but they’re certainly going to understand what they want – and they’re going to see that going to the cloud won’t work for every use case.

“There are a lot of companies out there right now that have existing software and may want to start incorporating an AI or camera-based element into it, but they don’t have the in-house capability. We can do that for them.”

“We are very partner-friendly, which is important for the markets we’re in,” said Woollard. “We don’t need somebody to come to us and commit to 10,000 boxes for us to get to work – but don’t get me wrong, we love that. We really don’t need that kind of commitment to lean in and work with you or customize an existing box or make something purpose-built.”

J-Squared’s Stronghold EMI/EMC cabinets meet MIL-SPEC tests for naval deployments. (Photo: J-Squared Technologies)

J-Squared’s Stronghold EMI/EMC cabinets meet MIL-SPEC tests for naval deployments. (Photo: J-Squared Technologies)

Historically, J-Squared offered a generic computer platform for a range of industries. Each could be modified with different processing power or input/output devices for specific applications, but it was essentially one size fits all.

“We’re starting to bring out computing solutions that are specific to certain end applications,” said Gibson. “One of the best examples of that is with naval communication on military ships, where we’ve designed a whole family of solutions. Agriculture is another example of an application where the box design will be skewed toward an application.”

Woollard said most customers come to J-Squared looking for a specific product but discover the company can do much more. It now supports the entire product lifecycle – design, production, testing, repair and maintenance.

“We’ve expanded our product portfolio beyond the TRAX product line into other products for mining and other markets, and now we’re doing more solution-based system integration work,” said Gibson. “For example, today we have the capability to assemble a turnkey hardware solution that includes a TRAX computer with a display, GPS antenna and all the cables to power a fleet management system. Another area where we’re really starting to get traction in the software space, where we’re building solutions that use our software and our hardware. But at the core, at the center of the universe for us, is rugged computing.”

This article originally appeared in the January-February 2025 issue of Power Progress.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM