Navigating the complex world of battery logistics

12 January 2025

The world of battery shipping and logistics can often feel like trying to complete a puzzle with pieces that don’t seem to fit.

With an energy transition underway in which many technologies — and even entire markets — are switching to electric power, the batteries used in battery electric vehicles (BEV), forklifts and other off-highway equipment all have different form factors and unique chemistries, weights and capacities.

Regulators are playing catch-up with these technologies and working to apply the right rules and guidelines for safely shipping batteries around the world. For those who don’t refer to these regulations on a routine basis, they can be complex and challenging.

Your best resource is to work with professionals who are knowledgeable and have extensive experience applying regulatory requirements while understanding the best practices to enhance safety and reduce unnecessary expenses. However, there are some basic guidelines to keep in mind when it comes to navigating battery logistics.

Regulatory Complexities

Bob Richard, president of HazMat Safety Consulting (HSC), said, “When shipping lithium batteries, it is essential to understand why a regulation is written and how to practically implement it into your company. These regulations are dynamic and continually changing.”

Firefighters cut a hole in a burning truck in Columbus, Ohio on April 18, 2024. The Columbus Dispatch reported that the truck contained lithium-ion batteries. (Photo: USA Today Network via Reuters Connect)

Firefighters cut a hole in a burning truck in Columbus, Ohio on April 18, 2024. The Columbus Dispatch reported that the truck contained lithium-ion batteries. (Photo: USA Today Network via Reuters Connect)

Bluewater Battery Logistics recently partnered with Virginia-based HSC to assist battery transport stakeholders in addressing the complexities of battery logistics. Richard has served as the chairman of the United Nations Sub-Committee of Experts on the Transport of Dangerous Goods as well as Deputy Associate Administrator for the U.S. Dept. of Transportation (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA).

PHMSA oversees the safe transport of all materials, including batteries, via all modes of transit. PHMSA has the final say when it comes to shipping batteries in the United States. Its regulations are designed to keep everyone safe, and they cover everything from how batteries are packaged to the labels that must be displayed.

Hazardous material regulations are addressed by PHMSA’s Office of Hazardous Materials Safety. DOT also publishes guidelines for shippers and stakeholders, such as the “Lithium Battery Guide for Shippers,” which not only describes shipping requirements in a variety of scenarios, but “refers to the regulatory requirements for a specific lithium cell/battery type, configuration, and size,” as DOT said in the publication.

International shipping, meanwhile, requires knowledge of even more standards and regulations. You’ll need to be aware of the standards set by the International Civil Aviation Organization (ICAO) and the International Maritime Dangerous Goods (IMDG) Code. These organizations have their own sets of rules that are just as crucial to follow.

Marc Trent, CEO of Poole, England-based vehicle recycler Charles Trent Ltd, opens up a specially-built, fire-safe container for batteries salvaged from recycled electric vehicles and hybrids on June 7, 2023. (Photo: Reuters/Nick Carey)

Marc Trent, CEO of Poole, England-based vehicle recycler Charles Trent Ltd, opens up a specially-built, fire-safe container for batteries salvaged from recycled electric vehicles and hybrids on June 7, 2023. (Photo: Reuters/Nick Carey)

The ICAO, for instance, has a Dangerous Goods Panel (DGP) that addresses how to safely ship equipment and vehicle batteries via air. They are broadly addressed in an annex to the Convention on International Civil Aviation — Annex 18: the Safe Transport of Dangerous Goods by Air. Specific instructions for packing and shipping batteries are included in an ICAO document (Doc 9284) called “Technical Instructions for the Safe Transport of Dangerous Goods by Air.”

The IMDG Code, by comparison, is a product of the International Maritime Organization (IMO). It speaks to the safe transport of batteries via maritime transport. On its website, the IMO said that the code “sets out in detail the requirements applicable to each individual substance, material or article, covering matters such as packing, container traffic and stowage.” It is updated biennially.

Differing Battery Conditions

Compounding the situation are the significant differences that exist among new batteries, end-of-life batteries and those determined to be damaged, defective or recalled.

New batteries, for instance, usually have fewer restrictions, while end-of-life batteries and damaged batteries require more stringent handling due to their potential hazards. Batteries headed for recycling may have different sets of requirements — limited state of charge, marking and labeling, packaging, etc. — compared to those batteries headed for their second-life applications or repair or refurbishing for their original application. The uncertain status of recalled batteries means shipping them comes with a challenging set of requirements.

Packaging and Labeling

Defective batteries require shippers to take extra precautions because they can leak harmful electrolytes or catch fire due to a thermal run-away event. For that reason, proper packaging is not just a formality; it’s a necessity.

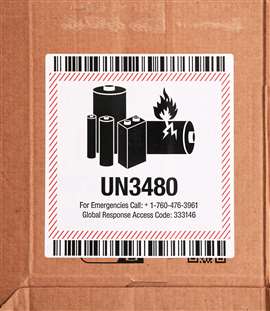

A battery warning label on a package for transporting lithium-ion batteries. (Photo: AlexGo via Adobe Stock)

A battery warning label on a package for transporting lithium-ion batteries. (Photo: AlexGo via Adobe Stock)

Most battery shipments must meet specific UN-approved packaging requirements to ensure that they survive the journey intact without posing a health and safety risk.

Getting packaging guidance that is specific to the weight, power output, condition and chemistry of defective batteries is essential, especially for larger or heavier batteries for which the regulations require extra measures to prevent thermal events during transportation.

Equally important is package labeling. Every package must display the correct hazardous materials labels along with the appropriate UN markings. This isn’t just about compliance. It’s about communicating the risks to people handling the shipment, including emergency responders.

Finally, accurate shipping papers that detail the contents, handling instructions and emergency contact information for the battery shipment are critical because they ensure that if something goes wrong, everyone knows how to respond.

Employee Training

About the Author

Max Khabur is marketing director for Los Angeles, Calif.-based Bluewater Battery Logistics. Email: [email protected]

Training — especially hazardous materials training — is one of the most effective ways to ensure safe and compliant shipping. Giving your team members detailed, clear and straightforward instructions tailored to your everyday operations plays a critical role in the shipping process.

This is not as simple as providing employees with access to DOT and related regulations. Instead, Khabur said there must be a clear set of instructions for employees to follow throughout the shipping process. This includes processes for reporting incidents or near-misses.

Clear communication is crucial and consistent with establishing a corporate safety culture. It empowers your team to take immediate action and learn from any challenges they face.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM