Read this article in French German Italian Portuguese Spanish

Cooper engines, gen-sets coming to North America

10 December 2024

Wisconsin-based K5 Power to lead with 1.2 L two-cylinder engine.

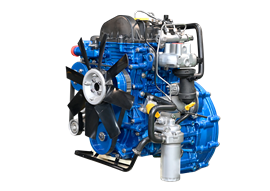

K5 Power said it will enter the North American market with Cooper Corp.’s 1.2 L two-cylinder water-cooled engine. (Photo: K5 Power)

K5 Power said it will enter the North American market with Cooper Corp.’s 1.2 L two-cylinder water-cooled engine. (Photo: K5 Power)

K5 Power is bringing a new engine brand to North America, and the Menomonee Falls, Wis.-based company said it believes the timing is right. The engine maker, Cooper Corp. Pvt. Ltd., has long been a component supplier to global engine manufacturers. The company makes more than 20-million-cylinder liners a year for a long list of brands and a wide range of sizes and applications.

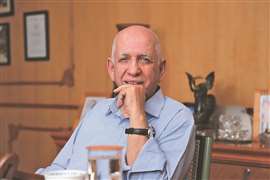

The Cooper group made India’s first diesel engine in 1922. Over the next several decades it operated as a machine shop. After current Chairman and Managing Director Farrokh N. Cooper took charge of the business, the Satara, India-based company expanded its product line as well as its manufacturing footprint in different directions. Today, Cooper has 13 factories across 100 acres. It employs nearly 3,000 people, 300 of whom are engineers.

A complete engine

In 2004, Cooper contracted with British engineering consultancy Ricardo for the development of its own range of internal combustion engines. Today, the company manufactures and sells diesel, natural gas, liquid petroleum gas and biofuel, air- and water-cooled engines from 1.2 to 7.8 L in two-, three-, four- and six-cylinder configurations. Vertically integrated with foundry and machine work completed onsite, Cooper builds each engine in a dedicated facility. Its relationship with Ricardo continues to this day.

The engines can be found in construction and agricultural equipment as well as marine and pump applications in around 30 countries. Shortly after introducing its two-cylinder engine, the company also began building gen-sets that are equipped with its own engines. K5 Power said the engines and gen-sets have earned a solid reputation for their low noise and vibration, durability and low operating costs as well as many other features and benefits to the end customer and user.

Cooper Corp. Chairman and Managing Director Farrokh N. Cooper. (Photo: K5 Power)

Cooper Corp. Chairman and Managing Director Farrokh N. Cooper. (Photo: K5 Power)

Coming to America

As a multifaceted organization with shipping, inventory, warehousing and foundry expertise, the K5 Power team has worked with Cooper Corp. since 1996, when it began representing Cooper’s manufacturing expertise to clients in the United States. In addition to the cylinder liners for which it has become widely known, it also supplies pistons, crankshafts, cylinder heads and blocks, valve seat inserts, flywheels and more.

When the engines and gen-sets were introduced a decade ago, Cooper had its sights set on the North American market, but domestic sales climbed so rapidly the company opted to save its resources and focus on India and other countries.

Since then, the government of India has focused on clearing the region’s air. In July 2023, the country mandated its CPCB IV+ emission standards for power generation engines, which are enforced by the Central Pollution Control Board (CPCB). Compared to the previous standard, the regulation resulted in a 90% reduction in particulate matter (PM) and nitrogen oxide (NOx) concentrations. It also established a single standard for prime and standby use gen-sets. All fuel types for engines with a power output up to 800 kWh are covered by CPCB IV+.

K5 Power said the mandate also made India’s emissions standards align and, in some cases, exceed those in Europe and the United States and provided a new opportunity for the team in Wisconsin to collaborate with Cooper.

“As Cooper went through the process of getting its engines certified through CPCB IV, they’ve found that those requirements are, in some cases, even more stringent than EPA requirements, and now they’re comfortable that their engines will meet the regulations for this country,” said Andy Kasun, a team member for K5 Power. “For us, it’s now a matter of deciding which of the engines we want to supply at first and then getting those engines here. We will be building an engine distribution operation that includes the gen-sets.”

Cooper Corp. has manufactured a range of engine sizes in India for a decade, including this four-cylinder water-cooled example. (Photo: K5 Power)

Cooper Corp. has manufactured a range of engine sizes in India for a decade, including this four-cylinder water-cooled example. (Photo: K5 Power)

Engine selection

Kasun said they’re leading with Cooper’s 1.2 L two-cylinder engine. The version the company will certify with the U.S. Environmental Protection Agency (EPA) is a water-cooled, natural gas, turbocharged version rated 35 hp at 1,800 rpm. The engine is used in Cooper’s 25 kVA generator, which will also be made available.

Next up will be the same engine with a different turbocharger rated 44 hp at 3600 rpm. That natural gas fueled engine is used in a 33 kw generator.

Both engines are based on a heavy-duty bed plate architecture with compacted graphite heads and are equipped with hydraulic lash adjustment, automatic belt tensioning, offset crankshaft and a four-valve overhead cam.

“The reason we started with that engine is because what’s currently available in the gen-set market in that power range fueled with natural gas is either air-cooled or are retrofitted automobile engines,” said Kasun. “This engine was designed and built to be a diesel and a natural gas engine. It’s very robust, and we feel it’s a great entry point into the market.

“These engines are really for someone looking for a better option that offers less noise. It’s a very quiet engine. Gen-set customers have also found that liquid cooled is the way to go when their power is out for a lengthy period of time. Because of stress to the grid and severe weather events, it’s not unusual to have to go without power several times a year where the gen-set is running three or four days and it’s 105 F outside. Those gen-sets need an engine that is more robust.”

K5 Power said the gen-sets and engines will be branded as Cooper but they will also be made available for private labeling. The company is currently developing a dealer and distribution network nationwide.

This article originally appeared in the November 2024 issue of Power Progress.

Cooper has used the engines in its own gen-sets, as well, including this 22 kW model. K5 Power plans to sell the company’s gen-sets in North America. (Photo: K5 Power)

Cooper has used the engines in its own gen-sets, as well, including this 22 kW model. K5 Power plans to sell the company’s gen-sets in North America. (Photo: K5 Power)

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM