43rd Engine Yearbook shows second wind for engines

08 July 2022

Samuel Clemens, better known under the pen name Mark Twain, once supposedly told a reporter that “the rumors of my demise are greatly exaggerated.”

Mr. Clemens, meet the combustion engine.

Because despite all of the negativity surrounding fossil fuels and the evolving promise of new technologies like electrification and hydrogen fuel cells, it appears that over the last 12 months, engines have started to get a bit of a second wind.

The most obvious indication of that can be seen on the chart below (NAFTA Engine Production - May 2022), provided by Power Systems Research (info@powersys.com), the global consultancy that tracks engines. Looking at production in the North American region, literally every power node in diesel, natural gas and gasoline engines saw improved sales over each of the last two years, some very improved. And that’s happened while coming off the COVID-19 pandemic and in the face of supply chain issues that just don’t seem to want to get any better.

Most engine manufacturers would be able to sell a lot more engines if they could either get components or, for those manufactured outside of the U.S., if they could just get engines.

Anecdotally, we’ve heard some suggest that they could see sales rise another 20% if they could just get products. There has also been talk of OEM customers being put on allocation, meaning that instead of X-number of engines, they’re only going to get Y, with Y being fewer. It’s got to be one of the most frustrating times in recent memory.

Compliance costs

At the same time, engines are still facing a lot of challenges. A case in point is the ever-increasing cost of compliance with upcoming engine emissions regulations. The Heavy-Duty Omnibus Regulations developed by the California Air Resources Board (CARB) set new standards, test procedures, warranty and reporting requirements for on-highway diesel engines used in trucks and buses. The new rules, which ratchet down NOx and greenhouse gas emissions significantly, go into effect in 2024.

There seems little question that engine manufacturers and their suppliers can once more step up their game and meet the new rules. But in this case, the age-old question “how much will that cost?” is the rub.

Estimates as to the compliance cost increase on 12 L and 13 L engines range from a low of just over $2000 per engine to a high of $80000, with the bulk of the guesstimates falling somewhere in between. For its part, CARB figures the additional per-vehicle price tag to be just under $8500.

Wherever the figure ends up, it’s going to be the latest in a long line of emissions-driven price increases that diesel engine and vehicle manufacturers – and ultimately vehicle operators – will have to find a way to again bear. And it won’t just be confined to California, since a lot of states tend to follow California’s lead on environmental issues, plus EPA is preparing its own regulations, which are not too dissimilar from CARB’s rules.

There are those who believe that part of the regulatory motivation is to make the cost of engines high enough that the financial difference between alternatives such as battery electrics and fuel cells won’t seem such a chasm. But that’s assuming a lot of things, particularly the existence of a widely available electric/hydrogen infrastructure, something that could cost trillions and take decades to create. In the meantime, there’s a lot of cargo to ship and other work to be done and engines will be around for a while to take care of that.

It should also be pointed out that the global engine manufacturing community isn’t exactly sitting around and waiting for something else to come along and take the business away. As shown in the following pages, engine manufacturers are doing what they ‘ve always done – working on products for today and innovating for tomorrow. As evidence of that, count how many times in the pages ahead you see the words “natural gas” and especially “hydrogen.”

It’s clear that we may be looking at something of a renaissance for engines in the next few years, with new technologies and new fuels bringing engines much nearer to the zero-emissions goal than seemed possible just a few years ago. A lot of that work is starting now, and you can read about a lot of it here. Enjoy!

AMERICAN HONDA MOTOR CO.

Honda Engines

Alpharetta, GA 30005

Website: engines.honda.com

Power Range

Gasoline: 1 to 24.8 hp

Power Systems News

Honda Engines, a business unit of American Honda Motor Co., Inc., has augmented its line of small, general-purpose engines with what the company called the first advanced electrified power unit for commercial OEM power equipment products for indoor and outdoor use.

Rated 2.4 hp at 3600 rpm, the Honda eGX incorporates a lithium-ion battery with a three-phase brushless dc electric motor and can be interchanged with a Honda GX internal combustion engine on selected outdoor power equipment.

The initial applications for the Honda eGX are for rammers (model GXE2.0S) power trowels and vibratory plate compactors (model GXE2.0H) used in the construction industry. Future applications are projected to include hydraulic power units and compressors. Additionally, a number of other commercial applications are being tested in various market segments, the company said.

More information on the Honda eGX will be included in the New Power Progress Yearbook in the July issue of Diesel Progress.

ARROW ENGINE CO.

Tulsa, OK

Website: arrowengine.com

Power Range

Diesel: 15 to 156 hp

Gaseous Fuel: 5 to 130 hp

New Engines

Arrow is launching new three-, four- and six-cylinder natural gas engines. The KP6 is a 6.5 L, inline six-cylinder naturally aspirated engine rated 95 hp. It is certified to EPA stationary prime and standby and non-road mobile regulations and can operate on natural gas, LPG and wellhead gas, the company said. A limited launch was scheduled for June 2022.

The KP3 is a 3.1 L naturally aspirated, three-cylinder engine rated 38 hp, EPA-certified (stationary prime and standby non-road mobile) that can operate on natural gas, wellhead gas or LPG. It will be launched in the July-August timeframe, Arrow said.

Finally, the KP4 is a 4.2 L naturally aspirated, four-cylinder rated 47 hp. Designed for non-certified oil & gas applications, it’s targeted for an August debut.

Arrow said the engines will initially also be available in generator-drive configurations, including radiator, flywheel, electronics and engine controls.

Later this year, the company said it is aiming to launch the turbocharged and charge air-cooled KP3TA, a 3.1 L, three-cylinder engine rated 58 kWe for gen-set applications, while the 8.8 L turbocharged and charge air-cooled KP8TA, rated 165 kWe, is expected in early 2023.

These engine launches highlight Arrow’s moves outside its traditional oil & gas focus to more general industrial engine applications, particularly power generation.

BRIGGS & STRATTON

The Vanguard 400 EFI/ETC engine. (Photo: Briggs & Stratton)

The Vanguard 400 EFI/ETC engine. (Photo: Briggs & Stratton)

Vanguard Commercial Power

Wauwatosa, WI

Web: www.vanguardpower.com

Power Range

Gasoline: 4.9 to 40 hp

Gaseous Fuel: 6.5 to 37 hp

Single-cylinder Engines

Over the past 12 months, Vanguard, a Briggs & Stratton brand, has continued to expand its single-cylinder engine range that first debuted in 2018.

The newest 400 EFI/ETC engine is designed to leverage electronic fuel injection (EFI) and electronic throttle control (ETC) technology to enhance efficiencies and reduce downtime for applications within the construction, agriculture, landscape and recreation equipment markets. The engine has bore and stroke dimensions of 87 x 67 mm for a displacement of 408 cc and is rated 14 hp gross.

The engine’s EFI system provides better fuel efficiency, improved overall performance and quick load acceptance, the company said. By pairing the EFI technology with an ETC system, the engine can provide smooth and consistent power through a broad range of load conditions.

The 400 EFI/ETC also incorporates all-weather chokeless starting and, unlike most fuel-injected engines, does not require a battery for starting. This, the company said, eliminates the bulk, weight and maintenance of a battery on board.

CATERPILLAR

Deerfield, IL

www.cat.com/industrial

Power Range

Diesel: 10.9 to 6597 hp

Gaseous Fuel: 95 to 8180 hp

New Engines

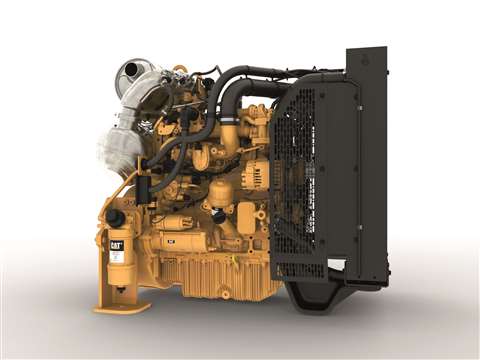

Caterpillar has launched a range of drop-in engines targeting the construction and materials handling industries. The Cat C2.8 and C3.6 industrial power units (IPUs) utilize a highly integrated design that saves customers time on engineering and installation, the company said. Common rail direct injection engines with a turbocharged or turbocharged aftercooled air system, the C2.8 and C3.6 meet EU Stage 5, U.S. EPA Tier 4 Final and Japan 2014 emission standards.

Caterpillar’s C3.6 IPU. (Photo: Caterpillar Inc.)

Caterpillar’s C3.6 IPU. (Photo: Caterpillar Inc.)

For ease of installation, the IPUs are equipped with full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounting for the ECM and fuel filter. This results in a plug-and-go design that Cat said saves the equipment manufacturers time through minimal engineering or design work, while still delivering the performance and efficiency customers expect from Caterpillar.

The engines are offered in ratings ranging to 74 hp for the C2.8 and to 134 hp for the C3.6. Full product support for the IPUs is provided by the global Cat dealer network.

Caterpillar announced it is offering a whole-machine telematic solution that helps equipment manufacturers provide equipment owners and operators with the ability to view critical data output in real-time and better understand – and make use of – their machine’s operation. Leveraging the company’s years of experience with asset health monitoring, customers using this technology can locate, track and manage all of their connected assets independently.

Able to be integrated with existing telematics regardless of brand, the engine-ready solution can help provide a clear picture of a machine’s health by collecting all the machine data and displaying the results through an online dashboard. Users of the system can use it to monitor various functions, including machine location, uptime, fuel use, engine status and maintenance alerts. Data is customizable and reports can be scheduled and shared.

Equipped with remote services capabilities, the engine-integrated telematics solution can help minimize downtime via remote troubleshooting that can run diagnostic testing and pinpoint potential issues while the machine is in operation. If a repair is required, an OEM or dealer technician would be alerted and be able to complete the repair correctly in a single visit, Cat said.

CUMMINS INC.

Columbus, IN

Website: www.cummins.com

Power Range

Diesel: 49 to 4400 hp

Gaseous Fuel: 49 to 2680 hp

New Engines

Cummins announced what it called the industry’s first unified, fuel-agnostic engines. The new platforms, the first of which is expected to be launched in 2024, will be suitable for a wide range of on- and off-highway applications and will use engine blocks and core components that share common architectures, optimized for different low-carbon fuel types.

Derived from a common base engine, they will have a high degree of parts commonality. Below the head gasket, each engine will largely have similar components and above the head gasket will be different components for different fuel types. Each engine version will operate using a different single fuel.

This new design approach will be applied across the company’s B-, L- and X-Series engine portfolios, which will be available for clean diesel, natural gas and hydrogen. This technology approach will allow end users to select the right powertrain for their application and duty cycle with the lowest CO2 impact, Cummins said.

Common engine footprints will reduce vehicle and equipment manufacturer complexity and allow them to offer a range of fuel capabilities depending on customer needs, the company said. Parts commonality can provide similar troubleshooting and service intervals with minimal costs to train technicians and re-tool service locations.

Gas Engines

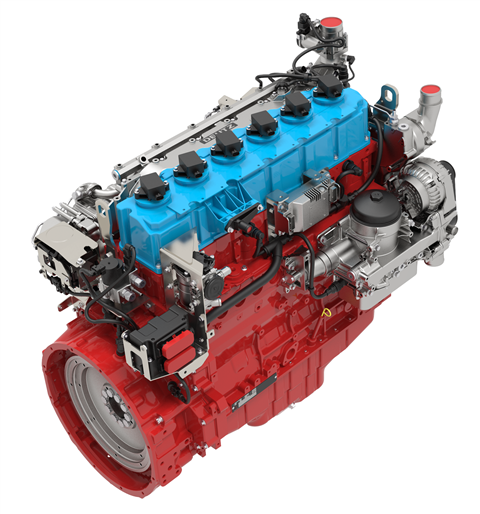

The Cummins X15N gas engine. (Photo: Cummins Inc.)

The Cummins X15N gas engine. (Photo: Cummins Inc.)

As part of the fuel-agnostic program, Cummins said it will bring to market a 15 L natural gas engine for heavy-duty trucks. The engine will offer ratings up to 500 hp and 1850 ft.-lb. of torque. Cummins said it is expected to weigh 500 lb. less than comparable current 15 L diesel engines while not requiring selective catalytic reduction (SCR) to meet 2024 California or Environmental Protection Agency emissions standards. When powered with renewable natural gas (RNG), the system can be credited with a neutral to negative carbon index, resulting in net greenhouse gas (GHG) emissions at or below zero, the company said.

Hydrogen

Cummins said the universal 15 L platform for heavy-duty is also the basis for the hydrogen internal combustion engine currently part of the UK government supported Brunel project, which also includes the company’s medium-duty 6.7 L engine.

The development of the 6.7 L hydrogen engine will focus on medium-duty truck, bus and construction applications, such as excavators and wheel loaders. The 15 L platform offers the potential to bring hydrogen-fueled engine capability to heavy-duty long-haul trucks.

Cummins global technical centers will work together to achieve commercial viability for the H2-ICE project on a global basis. Part of the development work to be undertaken at Cummins’ Darlington, UK, facility will be supported by a funding award recently received from the UK government, provided through the Advanced Propulsion Centre.

Using proven and existing engine platforms for the H2-ICE program also means that Cummins will be able to use its existing engine production facilities and service support network, reducing costs and improving efficiency. In addition, the company can reduce vehicle and equipment re-development timelines, as many existing driveline components can be retained when paired with the hydrogen-fueled engines.

Corporate News

Cummins made a series of acquisitions earlier this year. In January, it acquired a 50% equity interest in Momentum Fuel Technologies from Rush Enterprises. The joint venture between Rush and Cummins will manufacture Cummins-branded natural gas fuel delivery systems for the commercial vehicle market in North America.

In February, Cummins and Meritor announced a definitive agreement through which Cummins will acquire Meritor, a global supplier of drivetrain, mobility, braking, aftermarket and electric powertrain solutions for commercial vehicle and industrial markets, for approximately $3.7 billion. The deal is expected to close by the end of the year.

Also in February, Cummins agreed to acquire Jacobs Vehicle Systems (JVS), a subsidiary of Altra Industrial Motion Corp., and a supplier of engine braking, cylinder deactivation, start and stop and thermal management technologies. The deal, worth $325 million, closed in April and is intended to provide growth opportunities for Cummins’ current and future advanced diesel engine platforms.

DAEDONG CORP.

Daegu, South Korea

Website: daedong-kioti.com

Power Range

Diesel: 11 to 140 hp

New Engines

Daedong has developed a pair of new diesel engines. The 3L123 is a three-cylinder, 1.23 L, liquid-cooled engine rated 24.5 hp at 3000 rpm. The 2L082 is a two-cylinder, 0.82 L diesel available in two ratings – 11 hp at 2200 rpm and 16 hp at 3000 rpm.

Both of the new engines are naturally aspirated with flexible design architecture that allows filters to be positioned on either side, with single-side servicing an option for easier maintenance. The engines offer improved cold start performance, the company said, with an offset piston that results in reduced vibration and noise and improved oil consumption.

Both of the engines meet EPA Tier 4 Final and EU Stage 5 emissions standards, Daedong said.

DETROIT DIESEL CORP.

Detroit’s Gen 5 DD15 diesel. (Photo: Detroit Diesel)

Detroit’s Gen 5 DD15 diesel. (Photo: Detroit Diesel)

Redford, MI

Website: demanddetroit.com

Power Range

Diesel: 200 to 600 hp

Engine Updates

Detroit has developed Gen 5 versions of its DD13 and DD15 engines used in Freightliner and Western Star trucks. The 12.8 L DD13 is available in ratings from 370 to 525 hp with torque from 1250 to 1850 lb.-ft. while the 14.8 L DD15 offers ratings from 425 to 505 hp, with torque from 1550 to 1850 lb.-ft.

The Gen 5 updates include an all-new aftertreatment system and other enhancements aimed toward further increasing performance, durability and efficiency.

Key improvements to the design of the DD13 and DD15 include a new swirl piston design for better combustion; new turbochargers for more responsive torque performance and improved thermal management for extended idle and low-load PTO operation for fewer aftertreatment regenerations. Results include DPF service intervals extended by over 16% and fuel efficiency gains up to 4%.

Emissions Technology

Detroit’s new aftertreatment system on the DD13 Gen 5 and DD15 Gen 5 engines is smaller and 60 lb. lighter than previous systems while increasing NOx conversion and, dependent on duty cycle, allowing increased diesel particulate filter service intervals, the company said.

Service

This spring, Daimler Truck opened its expanded Detroit Service Training Center, which will be used to train technicians in electric powertrain service, battery maintenance and full truck repair.

Detroit also has announced new products and services to support fleets and customers in the deployment of all-electric trucks. These include Detroit eConsulting, to help customers navigate electric truck conversion, and Detroit eFill chargers, a full line of commercial vehicle charging stations designed for seamless integration with the Detroit ePowertrain found in Freightliner eCascadia and eM2 trucks.

New Corporate Developments

Detroit Diesel is a subsidiary of Daimler Trucks North America. In 2021, parent company Daimler split into two entities – Mercedes-Benz Group, which focuses on passenger vehicles, and Daimler Truck, whose brands include Freightliner, Detroit, Fuso, Western Star and Thomas Built Buses.

DEUTZ CORP.

Deutz’s TCG7.8L Hydrogen engine. (Photo: Deutz Corp.)

Deutz’s TCG7.8L Hydrogen engine. (Photo: Deutz Corp.)

Norcross, GA

Website: www.deutzamericas.com

Power Range

Diesel: 24 to 1005 hp

Gasoline: 35 to 52 hp

Gaseous Fuel: 35 to 52 hp

Hydrogen: 200 to 295 hp

New Engines

Deutz is in production with its new four-cylinder TCD 5.2 L diesel, a 5.2 L inline engine available in ratings of 134 to 228 hp.

The turbocharged and charge air-cooled engine is designed as a downsized alternative to larger six-cylinder engines. It incorporates the Deutz Common Rail (DCR) injection system and electronic engine control that, with aftertreatment, allows it to meet EPA Tier 4 Final, EU Stage 5 and China 4 emissions regulations.

New Engine Ratings

Deutz has developed high-power and high-torque versions of its four-cylinder TCD2.9 L diesel. The high-power engine can deliver up to 100 hp, a 25 hp bump from the standard engine. The high-torque engine offers 295 lb.-ft. of torque, up from the 221 lb.-ft. of the standard engine.

Hydrogen

Deutz said its TCG7.8L Hydrogen engine has begun operation in generator sets and locomotives. The six-cylinder, 7.8 L unit is based on an existing engine design and is rated 295 hp. It is scheduled to begin production in 2024.

Corporate News

David Evans was named president and CEO of Deutz Corp. in April. He succeeded engine industry veteran Bob Mann, who retired after 16 years in that role. Prior to Deutz, Evans held a number of senior positions at Oerlikon Drive Systems Americas and Fairfield Manufacturing, as well as at SMW Automotive and TRW Automotive.

Deutz Corp. opened Deutz Power Center West in Las Vegas, the eighth power center the company has opened since it established the first location seven years ago. The site provides dedicated application engineering and technical sales resources for OEMs that utilize Deutz products in their equipment, as well as service coverage for much of the western U.S.

ENGINE DISTRIBUTORS INC. (EDI)

Blackwood, N.J.

Website: www.edi-dist.com

Power Range

Gasoline: 25 to 250 hp

Gaseous Fuel: 25 to 250 hp

New Engines

After being delayed by global supply chain issues, EDI is set to launch a pair of spark-ignited Ford Power Products engines for industrial applications.

The LSG635 is a 3.5 L, V6 engine that can operate on natural gas, LPG and LP vapor (LPV). Expected to debut before the end of the second quarter, it delivers up to 115 hp on LPG. A gasoline version will be available late this year, the company said.

In the third quarter, EDI aims to launch the WSG873, a 7.3 L V8 engine that can operate on LPG, LPV and natural gas and offers ratings up to 245 hp on LPG. A gasoline version is planned for later in 2022, as is a turbocharged model, EDI said.

The LSG635 incorporates an aluminum block and head, chain-driven camshafts with automatic tensioning, a structural front cover with a deep sump oil pan and forged steel crankshaft. The larger WSG873 utilizes a cast iron block with structural front cover, forged steel crankshaft and in-block camshaft.

Both engines have a set-for-life valvetrain capable of accommodating a range of fuels, a closed loop fuel control, electronic engine management system and next-generation engine governor.

FAIRBANKS MORSE DEFENSE

Beloit, WI

Website: www.fairbanksmorse.com

Power Range

Diesel: 4827 to 25747 hp

Gaseous Fuel: 2100 to 4865 hp

Corporate News

Fairbanks Morse Defense (FMD), a portfolio company of Arcline Investment Management (Arcline), made a series of acquisitions over the past year. They included:

- Federal Equipment Co. (FEC), which significantly expands FMD’s product capabilities and service solutions for shipyard, defense and industrial customers.

- Fluid Filtration Specialists LLC (FFS), a supplier of flushing and filtration services for marine vessels and other facilities that operate large, highly sophisticated engines and systems.

- Hunt Valve Co., a specialty manufacturer of naval valves and electromechanical actuators that expands FMD’s service solutions for shipyard, defense and industrial customers.

FPT INDUSTRIAL

Burr Ridge, IL

Website: ftpindustrial.com

Power Range

Diesel: 38 to 1000 hp

Gaseous Fuel: 75 to 460 hp

Marine Engines

FPT Industrial has developed a new keel cooling system for its N40 250 E, N67 450 N and N67 570 Evo marine engines. The system is designed for vessels operating in brown and shallow waters looking to avoid the issues linked to seawater circuits.

Positioned along the keel or incorporated into the hull, the system is in constant contact with the water, enabling the efficient transfer of heat between the engine coolant and the water without circulation of salt water into the engine. This, FPT said, protects the engine from seawater corrosion and avoids continuous seawater filter obstruction and damage to the seawater impeller.

Diesel Hybrid

FPT Industrial’s F28 gas engine. (Photo: FPT Industrial)

FPT Industrial’s F28 gas engine. (Photo: FPT Industrial)

FPT Industrial has shown its vision of the powertrain of the future with the F28 Hybrid, a diesel engine paired with an e-flywheel that the company said results in an efficient, compact and sustainable solution for off-road applications.

The 2.8 L hybrid engine was developed to offer enhanced productivity and efficiency in compact equipment. With four inline cylinders, the engine delivers a maximum power of 74 hp, while the electric motor/generator adds 27 hp of continuous power and 40 hp of peak power. Light construction machines such as skid-steer loaders, drum rollers and backhoe-loaders can benefit from that peak power at certain times to complete their missions more efficiently, the company said.

In addition, the F28 Hybrid incorporates an optimized Start & Stop system for improved efficiency and a smoother engine start.

Emissions Technology

FPT said its newest patented HI-eSCR aftertreatment system is able to reduce the NOX levels more than 95% to meet EPA Tier 4 Final and EU Stage 4 emissions regulations. With no DPF, the system is maintenance-free and improves productivity by avoiding downtime during operation for filter cleaning or replacement, the company said.

For EU Stage 5 applications, FPT Industrial will integrate a maintenance-free filtering device on its SCR catalyst, thus enabling compliance with tightened limits on PM emissions within a compact package. This second-generation HI-eSCR 2 system, applicable for engines above 75 hp and below 750 hp, will maintain the same aftertreatment dimensions of the current Tier4 Final/Stage 4 applications while requiring no machine redesigns or layout changes for machine upgrades to the next emissions level.

Alternative Fuels

FPT Industrial supplied F28 natural gas engines for two New Holland TK Methane Power crawler vineyard tractors that are powered by biomethane and utilized at the Fontanafredda winery in the Piedmont region of Italy. The two tractors are part of a project with the wine producer to produce the first 100% sustainable wine.

The F28 four-cylinder engines are compact 2.8 L models rated 74 hp with 243 lb.-ft. of torque. The engines are designed without exhaust gas recirculation and utilize a three-way catalytic converter. The two biomethane tractor prototypes use biomethane produced locally from the anaerobic digestion of agricultural waste.

FPT Industrial is testing dimethyl ether (DME) in an 11 L heavy-duty diesel engine that is part of a project funded by the Swiss Federal Office for Energy (SFOE). Similar to LPG, the chemical properties of DME allow for very low NOx and particle emissions while maintaining high engine efficiency. Since DME combustion produces practically no particle emissions, a comparably simple SCR system without a particulate filter may be enough to comply with strict emissions standards, FPT said.

The first experimental data is showing promising results in terms of CO2 reduction, FPT said, along with very low NOx and particle emissions and similar engine efficiency to a diesel.

HATZ DIESEL OF NORTH AMERICA

Waukesha, WI

Website: www.hatznorthamerica.com

Power Range

Diesel: 6 to 86 hp

Alternative Fuels

Hatz said its H50 Series and mechanical 1B and 1D series diesel engines are now approved for synthetic diesel fuels. These include XTL (X-to-liquid), BTL (Biomass-to-liquid), GTL (Gas-to-Liquid), HVO (Hydrotreated Vegetable Oils) or e-fuels (electrofuels) listed as meeting EN15940 diesel fuel specifications.

HYUNDAI DOOSAN INFRACORE

Website: www.hyundai-di.com

Power range

Diesel: 10.8 to 1353 hp

Gaseous Fuel: 174 to 613 hp

Marine Engines

Hyundai Doosan Infracore has launched a new marine engine for IMO Tier 3 applications. The DX12 engine delivers up to 550 hp and offers significantly improved power and fuel efficiency compared to existing products, the company said.

The new engine has bore and stroke dimensions of 123 x 155 mm and a total displacement of 11.1 L. Turbocharged and intercooled, the six-cylinder engine utilizes a common rail fuel system and high-efficiency SCR technology to meet the IMO standard, and it can also be operated on biodiesel (HVO) using vegetable oil or fuel produced using gas to liquid (GTL) technology.

Hyundai Doosan Infracore has developed marine versions of its DL06 and DL08 engines. The DL06 has a bore and stroke of 100 x 125 mm for an overall displacement of 5.9 L, while the DL08 displaces 7.6 L on bore and stroke dimensions of 108 x 139 mm. The DL06 offers ratings to 285 hp, while the DL08 goes to 380 hp.

Generator Engines

Hyundai Doosan Infracore has released the DX22, the company’s latest electronic engine for diesel generators. The 12-cylinder DX22 diesel has a displacement of 21.9 L on bore and stroke dimensions of 128 x 142 mm. It incorporates a high-pressure common rail fuel system to feature high power density of 995 kWe standby at 60Hz. The company said the cylinder block, cylinder head, crankshaft and other major components are manufactured using a high-strength design and have undergone thorough durability verification.

The DX22 generator engine has achieved EPA Tier 2 certification and also meets European Reach & RoHS regulations, the company said. A version meeting CN3 was introduced in the Chinese market at the beginning of 2022.

Hydrogen

Hyundai Doosan Infracore has started developing H2 engines of 11 L, and first firing is scheduled in early 2023. It is also planned for them to be installed in vehicles such as trucks and buses by the end of 2023 and to expand to industrial applications in the future.

Warranty

Hyundai Doosan Infracore said it has extended the basic warranty period for industrial G2 engines from three years/3000 hours to five years/3000 hours. In addition, the basic warranty period for medium/large emergency generator engines is five years and 1000 hours and the company plans to provide the same warranty for its newly mass-produced electronic engines such as the DX22.

Corporate News

Hyundai Doosan Infracore changed its name after becoming a subsidiary of Hyundai Heavy Industries Group’s construction machinery business last September. Hyundai Doosan Infracore is currently affiliated with Hyundai Genuine, an intermediate holding company in the construction machinery sector of Hyundai Heavy Industries Group.

Hyundai Genuine announced a goal of achieving $9 billion in sales and a 5% global market share by 2025.

INNIO WAUKESHA GAS ENGINES

Waukesha, WI

Website: www.innio.com/en/waukesha

Power Range

Gaseous Fuel: 160 to 5000 hp

New Engines

INNIO Waukesha Gas Engines has released the P48SE, a higher-output, standby version of its VGF engine. The 16-cylinder, rich-burn engine is part of the company’s plans to refresh its VGF product line, designated for gas compression and power generation applications.

The 48L P48SE engine is rated 1460 bhp at 1800 rpm for up to 200 hours per year at 70% load factor. It has an emergency standby power rating of 1460 bhp (1100 kWb) per ISO 8528-1, which allows for a net electrical power rating of 1 MW.

The new engine comes with INNIO Waukesha’s updated ESM2 controls system, which consists of an enhanced electronic control unit, a 12-in. touchscreen human machine interface (HMI), ignition module (IPMD2), flange-mounted ignition coils, electronic fuel valve, pre-catalyst wideband oxygen sensor and an electric starter.

The P48SE is initially available for 60 Hz applications, running on commercial quality natural gas. Initial engine shipments began last year, with open gen-set and radiator-mounted gen-set offerings to follow.

Emissions Technology

Waukesha’s reUp product offering includes complete engines, short and long blocks, as well as components that are purpose-built to extend the life of existing engine assets, reducing baseline emissions and avoiding environmental impacts associated with new engine manufacturing.

A Texas gas storage facility recently swapped out their lean burn engines for rebuilt VHP Series Five engines to become the first carbon-neutral gas storage facility in the nation. The Series Five was chosen for its ability to reduce about 90% of methane in the exhaust and reduce CO2e intensity by about 20% while also reusing the existing infrastructure including compressors and most of the package components. In addition to emissions and environmental benefits, Waukesha’s reUp program maximizes overall engine and fleet efficiency with longer service intervals and lower operating costs.

ISUZU MOTORS AMERICA, LLC

Plymouth, MI

Website: www.isuzuengines.com

Isuzu’s GenSet power unit. (Photo: Isuzu Motors)

Isuzu’s GenSet power unit. (Photo: Isuzu Motors)

Power Range

Diesel: 11.8 to 512 hp

Gaseous Fuel: 78.4 to 79.8 hp

Liquid Propane: 56.3 to 82.5 hp

Gen-set Power

Available power when needed has become even more critical today with unpredictable hurricanes, tornadoes and storms. According to Isuzu, its open GenSet diesel power units can quickly put standby power solutions into customers’ hands for multiple generator applications.

The Tier 4-certified, 3.0 L, four-cylinder 4J Series rated 95 hp at 1800 rpm and the 5.2 L, four-cylinder 4H Series rated 171 hp at 1800 rpm are open power units engineered to provide pre-tested and over 90% validated ready power. Isuzu’s designs incorporate the SCR system in an over-the-flywheel mounting and the units are built with common components for multiple configuration options, including adjustable skid base crossmembers for bolt-on flexibility.

Isuzu said that its Tier 4 and Stage 5 engines and power units, branded under Isuzu REDTech in the USA, are designed to deliver quiet, low-maintenance, fuel-efficient power for existing and new applications. Flexible DOC (diesel oxidation catalyst) or DOC+SCR aftertreatment, with vertical or horizontal SCR configurations, are available and most of the Isuzu product lines are available with five-year/5000-hour warranties, the company said.

Alternative Fuels

Isuzu’s alternative fuel engines and power units use natural gas or propane and can be equipped with a dual fuel system designed to allow the fuel source to be quickly reconfigured, eliminating complexity and downtime. The dual fuel power units can change from one fuel to another while on location and without shutting down the entire job site for the change, Isuzu said.

This means that when natural gas service is interrupted, the dual fuel engines and power units can be switched off and restarted using a readily available propane tank, said the company, to keep projects or emergency power running with a clean available fuel source.

JCB POWER SYSTEMS

Derby, United Kingdom

Website: www.jcb.com/en-gb/products/engines

Power Range

Diesel: 74 to 284 hp

Industrial Power Units

Due to what it called “the overwhelming success” of its IPU engine range, JCB has added additional engine dressing stations at its factory in Derby, England. The IPUs are designed to combine a JCB diesel engine with a completely JCB engineered installation package. Every bracket, fastener, clip and guard is subjected to thousands of hours of endurance testing both in the field and in the test cells, JCB said. The units target a broad range of applications, including crushing and screening, pumping, irrigation or quasi-static equipment.

JCB’s hydrogen engine. (Photo: JCB)

JCB’s hydrogen engine. (Photo: JCB)

Hydrogen

Over the last 15 years, JCB Power Systems said it has delivered significant improvements around air quality objectives related to its engines, with as much as a 98% reduction in NOx and particulate emissions from those manufactured in 2000. The company’s strategy to drive its products toward Net Zero includes multiple approaches including HVO and electric. However, JCB said the most important strand of its product strategy is hydrogen.

The company’s hydrogen internal combustion engine is based on the JCB Dieselmax 448 four-cylinder engine. To enable a largely drop-in solution, the bottom two-thirds of the engine are relatively unchanged, while on top is a new head and combustion system designed to support hydrogen as a fuel. The engine also incorporates additional venting for purging of any excess hydrogen fuel at shutdown.

JCB’s first hydrogen combustion engines were up and running by the end of December 2020, with numerous iterations developed since. Prototype machines have been running since 2021, and late last year, JCB announced a $138 million investment in hydrogen engine production, with the aim of providing the first H2 machines to customers by the end of the year.

Corporate News

Late last year, JCB reported that it had reached a production milestone of 750000 engines. The number covers engines built in the UK and India, which began assembling engines in 2011.

Distribution

JCB Power Systems has appointed new dealers in several global regions. They include GHP Group covering Russia and Latvia; LMA Industrial responsible for Argentina; DERCOMAQ in Chile; ERCESA in the Czech Republic and Slovakia; Pitteri Violini Spa in Italy and San Marino; and Dutch distributor Brinkmann & Niemeijer, which is now also responsible for Germany and the Benelux region.

JOHN DEERE POWER SYSTEMS

John Deere’s JD18 diesel. (Photo: John Deere Power Systems)

John Deere’s JD18 diesel. (Photo: John Deere Power Systems)

Waterloo, IA

Website: www.JohnDeere.com/jdpower

Power Range

Diesel: 48 to 906 hp

New Engines

John Deere Power Systems has released more information about its forthcoming JD18 engine.

New combustion technology means John Deere can offer an engine in the 700 to 907 hp (522 to 676 kW) power range without aftertreatment, meaning users have one less fluid to manage. The high-pressure common rail fuel system in the JD18 allows the engine to deliver optimized fluid consumption, the company said, plus the Diamond Like Coating (DLC) improves biodiesel compatibility and system robustness.

Uptime-focused controls offer improved diagnostic capabilities, enabling the ability to target the source of performance issues, the company said. The JD18 features a bedplate design, providing structural benefits for extreme durability, with the ability to be re-built two times. The engine also has Hydraulic Lash Adjustment (HLA), which offers a maintenance-free valvetrain, eliminating the need to reset the lash.

The new engines are scheduled to go into production this fall at Deere’s Engine Works facility in Waterloo, Iowa.

Technology

To advance its vision to integrate smart and sustainable technology innovations, John Deere has made strategic investments in two companies that are leveraging unique technologies for alternative fuel and electrification solutions.

In late 2021, Deere made an equity investment in ClearFlame Engine Technologies, a growing startup dedicated to the development of clean engine technology. ClearFlame’s solution is designed to enable low-carbon fuels like ethanol to be easily integrated into compression ignition engines, offering a more sustainable solution without compromising engine performance.

Earlier this year, Deere also acquired majority ownership in Kreisel Electric Inc., a battery technology provider based in Rainbach im Mühlkreis, Austria. Kreisel develops high-density electric battery modules and packs, as well as a charging infrastructure platform that utilizes its patented battery technology.

KAWASAKI MOTORS CORP., U.S.A.

Grand Rapids, MI

Website: KawasakiEnginesUSA.com

Power Range

Gasoline:14.5 to 38.5 hp

Corporate News

Kawaski has begun operation at its new Boonville, Mo., engine production facility. The Boonville plant is being used for manufacturing gasoline engines used in lawn and garden, commercial mower and industrial applications.

It is the second Kawasaki engine plant in Missouri. The company has been building engines at its Maryville. Mo., facility since 1989 and now manufactures 18 different models ranging from 14.5 to 38.5 hp at that site. No engine production was moved out of Maryville, as the new plant is being used to provide additional capacity.

The Boonville plant began with production of Kawasaki’s high-volume FR vertical shaft V-twin engines, which range from 18 to 24 hp. The company said it will also eventually build FS vertical shaft V-twins from 14.5 to 25.5 hp at the new facility.

Aftermarket

Kawasaki has continued to expand applications for its two ethanol-free fuel products optimized for outdoor power equipment. The Ktech Pre-Mixed 2-Cycle Fuel + Oil is intended to take the guesswork out of oil and fuel mixing for two-cycle equipment, incorporating 93 octane gasoline and 100% synthetic blend FD certified oil in a 50:1 mix.

The unleaded KTech Ethanol-Free 4-Cycle Fuel is formulated for four-cycle small gasoline engines and two-cycle engines when mixed with oil to engine manufacturer specifications. Kawasaki said the new fuel meets warranty requirements for all makes of engines.

KEM EQUIPMENT

Tualatin, OR

Website: www.kemequipment.com

Power Range

Gasoline: 43 to 104 hp (industrial)

Gasoline: 250 to 600 hp (marine)

Gaseous Fuel: 42 to 233 hp

KIRLOSKAR AMERICAS CORP.

Magnolia, Texas

Website: www.kirloskaramericas.com

Power Range

Diesel: 4 to 1250 hp

New Engines

Kirloskar Americas Corp., formerly KOEL Americas Corp., is the wholly owned subsidiary of Kirloskar Oil Engines Ltd. (KOEL) of India. Incorporated in 2015, the company was established with the strategic intent to enter the North American and Latin American markets.

KOEL is the flagship company of the Indian Kirloskar group that has a heritage of more than 120 years and more than 74 years of engine manufacturing experience. KOEL maintains four diesel engine manufacturing facilities in India that build products exported to more than 60 countries worldwide. KOEL manufactures more than 225000 diesel engines annually that are used for more than 100 applications in industries such as agriculture, power generation, construction, material handling, earthmoving, mining, offshore and agricultural, along with defense and maritime applications.

Kirloskar’s 2R550 diesel. (Photo: Kiloskar Americas)

Kirloskar’s 2R550 diesel. (Photo: Kiloskar Americas)

The company has recently developed and certified engines specifically for the U.S. market. Currently, Kirloskar Americas has a range of EPA-certified generator drive engines for emergency stationary applications, and the company said there are new products in the pipeline that will be released over in the coming months that target off-highway applications.

The existing Kirloskar product line for North America includes two EPA Tier 4 Final engines (the 2R550 and 3R550) rated 15.7 and 23.5 hp at 1800 rpm, as well as four engines meeting EPA’s Tier 3 regulations for standby gen-sets – the 4R810NA1 rated 48.7 hp and 30 kWe; 4R810TA2 rated 65 hp and 40 kWe; 4R810TA1 rated 95 hp and 60 kWe; and 4K1080TA1 rated 156 hp and 100kWe.

Kirloskar Americas is also introducing a new platform of compact diesel engines under 25 hp that meet Tier 4 Final emissions standards. The two- and three-cylinder engines have 0.55 L/cyl. displacements.

Other products to be launched over the next two years include a new platform of compact three- and four-cylinder engines covering 26 to 74 hp. The 1.65 and 2.2 L R550 series engines will be released with EPA Tier 4 Final certification for various off-highway applications and will incorporate common rail fuel systems, cooled exhaust gas recirculation (EGR) and DOC aftertreatment, the company said. Kirloskar Americas also has plans to introduce four-cylinder, 4.8 L engines to cover the 75 hp market.

The company’s KFP Series diesel engines are supplied to fire pump manufacturers around the world including in the United States for export. The KFP series engines are FM Global (FM) approved and Underwriters Laboratories (UL) listed, the company said. They were designed specifically for fire pump applications and cover 38 different ratings in a power band of 55 to 336 hp. Packaging of fire pump engines with base frames and other accessories has recently been started in partnership with Arrow Engine Co.

KOHLER ENGINES

Kohler, WI

Website: www.kohlerengines.com

Kohler’s KSD diesel. (Photo: Kohler Engines)

Kohler’s KSD diesel. (Photo: Kohler Engines)

Power Range

Diesel: 3.3 to 140 hp

Gasoline: 3 to 38 hp

Gaseous Fuel: 1 to 29 hp

New Engines

Kohler launched a new family of small diesels under 25 hp earlier this year. The Kohler Small Displacement (KSD) are the company’s most significant engine development since the launch of the Kohler Direct Injection Diesels in 2017.

The KSD diesels are three-cylinder engines with bore and stroke dimensions of 81 x 90 mm and an overall displacement of 1.391 L. The naturally aspirated models will offer ratings of 24.6 hp at 2200 rpm, with maximum torque of 66 lb.-ft. at 1800 rpm. Turbocharged models will have the same maximum horsepower, with torque rising to 77 lb.-ft. at 1500 rpm, while the turbocharged and charge-air-cooled engines will see torque top out at 88.5 lb.-ft. at 1400 rpm.

The KSD will also be available at launch with EU Stage 5 and EPA Tier 4 Final generator set ratings. For the 50 Hz markets, standby power ratings will be 17.4, 22.1 and 25.2 hp, while prime power ratings are 15.6, 19.9 and 22.9 hp. All 50 Hz ratings are at 1500 rpm. For the 60 Hz markets, standby ratings are 22.7 and 24.6 hp, while prime ratings are 21.8, 22.7 and 24.6 hp, all at 1800 rpm.

The new KSD engines are intended to eventually succeed the existing Kohler KDW series engines.

Hybrids

Following the changes brought about by the new emissions directive for off-road applications, Kohler has decided to expand its range of hybrid solutions, offering the choice of the most suitable engine for each application.

Two new Kohler Hybrid Energy Modules (K-HEM), incorporating electric and mechanical power sources, have been developed. The K-HEM 1003 combines a 24 hp KDW 1003 diesel engine and a 48 V electric motor/generator, while the K-HEM 2504 utilizes a 74 hp KDI 2504TCR diesel engine with a motor/generator.

HVO Fuels

Kohler Engines approved the use in Europe of EN15940-compliant HVOs for all its diesel engines – either pure or as a blend with conventional diesel. HVO is a renewable paraffinic fuel also known as synthetic diesel and renewable diesel. The engines will not require any kind of modification or specific upgrade to use HVO.

Corporate News

Early this year, Kohler Power acquired Curtis Instruments, a global supplier for EV and hybrid applications. The Curtis product portfolio incorporates motor speed controllers, HMIs and instrumentation, power conversion, CAN modules and other accessories. The acquisition expanded and diversified Kohler’s power portfolio by leveraging Curtis’ electrification expertise with Kohler’s established gasoline and diesel engine business.

The Kubota D902-K diesel. (Photo: Kubota Engine)

The Kubota D902-K diesel. (Photo: Kubota Engine)

KUBOTA ENGINE AMERICA CORP.

Lincolnshire, IL

Website: www.kubotaengine.com

Power Range

Diesel: 6.9 to 200 hp

Gasoline: 24.8 to 87.1 hp

Gaseous Fuel: 23.7 to 93.8 hp

New Engines

Kubota Engine America is now offering the newly developed D902-K diesel, the company’s first electronically controlled diesel engine below 25 hp. Kubota said the D902-K will bolster its diesel engine line as it responds to various regional emissions standards, including EPA Tier 4, Stage 5, China 4 standards and China’s Category 3 national smoke regulations, which will be implemented in December.

The newest member of Kubota’s Super Mini engine range, the D902-K, is an inline, liquid-cooled, three-cylinder diesel displacing 0.898 L and with bore and stroke dimensions of 72 x 33.6 mm. Maximum rated output is 24.8 hp at 3600 rpm, with a maximum torque output of 41.4 lb.-ft. at 2600 rpm.

The D902-K is equipped with a new Kubota-designed TVCR combustion system equipped with what the company called a one-of-a-kind common rail system that delivers a 5% increase in fuel economy over the mechanically controlled D902.

According to Kubota Engine America President Tomokazu Matsushita, the D902-K “allows manufacturers to easily replace the existing engine without the need to redesign the current machine. It will match current dimensions, structures and power takeoff of existing engine.”

The D902-K is capable of communicating via the Controller Area Network (CAN), which allows engine speed and torque to be controlled using signals from the vehicle and can also acquire engine operating data for telematics purposes.

Mass production of the D902-K is scheduled to begin this year.

Extended Warranty

Kubota Engine America is offering an extended engine warranty for new Kubota-powered air compressors, mobile elevated work platforms (MEWP), light towers and generators (excluding marine, RV and Kubota-branded units). The extended coverage allows customers to take advantage of Kubota Engine America service and support for an additional year, resulting in a better total cost of ownership for end users, the company said.

The new warranty is good for three years or 3000 hours, whichever occurs first, and is applicable on Kubota engines in new equipment operated in North America, South America and the Caribbean starting January 1, 2022.

Engines must be registered at the time of sale, which can be completed using Kubota Engine America’s service app. The service app is available for free download on both Apple and Android devices. It allows engines to be registered and includes a dealer locator. It also gives access to the Kubota Knowledge Center, which provides operator manuals and service maintenance information.

The company’s standard warranty remains in effect for all other applications, offering coverage for two years or 2000 hours.

LIEBHERR USA

Liebherr’s D966 engine, (Photo: Liebher USA)

Liebherr’s D966 engine, (Photo: Liebher USA)

Saline, MI

Website: www.liebherr.com

Power Range

Diesel: 241 to 5752 hp

Gaseous Fuel: 194 to 1421

Emissions

Liebherr said it has been focusing on how to address the challenges of greenhouse gas and NOx reduction, while continuously improving engine performance. As part of that effort, the Liebherr Components segment recently announced the results of a joint study with Tula at the International Engine Congress in Baden-Baden, Germany.

Based on simulations on Liebherr’s D966 engine, the study indicated that Tula’s diesel Dynamic Skip Fire (dDSF) software allowed for reductions of NOx tailpipe emissions by 41% and CO2 by 9.5%. Liebherr Components said it will continue designing “proof of concept” hardware for the integration of Tula’s dDSF software into its own engine system. As the next step, Liebherr will consider the integration of the dDSF software into other engines of its portfolio.

Liebherr said it also researching the development of hydrogen-fueled internal combustion engines and the company’s Fuel Systems business has been in development of a hydrogen fuel injection system. To accelerate these activities, Liebherr has made investments into additional test facilities.

Liebherr has also introduced HVO as another possible fuel for its engines. The use of the synthetic fuel allows customers to reduce greenhouse gas emissions up to 90% without a necessity for an engine replacement or adaptation, the company said.

LISTER PETTER ENGINE CO. LIMITED

Lister Petter’s Venus engine. (Photo: Lister Petter Engine Co.)

Lister Petter’s Venus engine. (Photo: Lister Petter Engine Co.)

Peterborough,U.K.

Website: www.listerpetter.com

Power Range

Diesel: 7.3 to 1072 hp

New Engines

Lister Petter said that over the last year, it has introduced several new engine series to augment its existing TR and Alpha diesels.

The Venus engine range is an advanced technology product that is synchronized to global requirements. Applicable in both automotive and construction machinery markets, Lister said it offers outstanding fuel economy, low vibration and reduced noise emissions. It also allows for dual frequency switching, which the company said makes it cost-effective.

Advantages cited by the company include the ability to operate at temperature extremes – cold starting down to -40º F and at high ambients up to 122º to 131º F – and 2000-hour overhaul intervals for important components. Lister Petter said the automotive and construction engines have more than 90% parts commonality to provide easy access for maintenance, and a high-capacity oil sump allows change intervals of 500 hours.

The Mars engine was designed in-house according to stringent requirements, the company said. It incorporates a common rail fuel system and dual turbocharging system with single air filter construction, which can lower the overall engine height, as well as a spiral-type fan for lower noise emissions.

Lister Petter said its Mercury engine technology is directly from Japan and offers low fuel consumption as well as low noise and vibration. Outputs range from 18 to 69 hp and its ease of maintenance makes it suitable for generator set applications, the company said.

Finally, the Starlite engines are rated from 17 to 96 hp. Based on what the company called a highly mature technology, they are targeted at generator set applications in Europe, America, Southeast Asia and Middle East.

Lister Petter said its products are supported by a network of global distributors. In North America, Lister Petter engines are sold through Kraft Power’s four locations, as well as Marindustrial in Ontario, Canada.

MAN ENGINES & COMPONENTS

Pompano Beach, FL

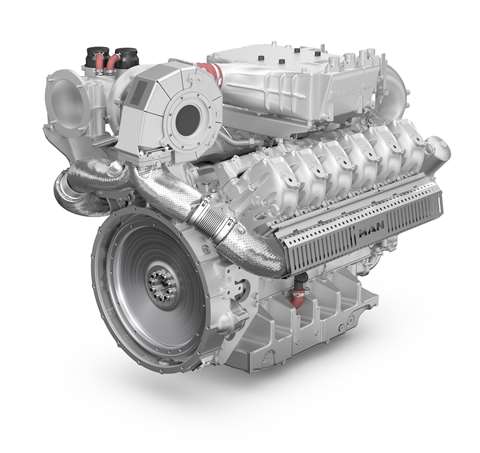

MAN’s E3872 gas engine. (Photo: MAN Engines & Components)

MAN’s E3872 gas engine. (Photo: MAN Engines & Components)

Website: www.man-mec.com

Power Range

Diesel: 147 to 1972 hp

Gaseous Fuel: 49.6 to 985 hp

New Engines

Earlier this year, MAN Engines unveiled its new MAN E3872 gaseous-fueled engine for power generation and combined heat and power (CHP) applications. The four-stroke spark-ignition gas engine is a V12 configuration with a displacement of 29.6 L on bore and stroke dimensions of 138 x 165 mm. The engine has a mechanical rating of 995 hp at 1500 rpm.

Marine Hybrids

MAN Engines has unveiled its Smart Hybrid technology, which teams a diesel engine with permanent magnet synchronous motor/generators that can deliver rated power of 247 or 493 hp, depending on the motor used. The motor is mounted to the diesel engine ahead of the marine drive and can be separated from the engine by an electromagnetic clutch.

The MAN Smart Hybrid system can be teamed with MAN’s D2862 (V12), D2868 (V8) and D2676 (inline six-cylinder) engines and allows for overall system outputs from 644 to 2500 hp.

Hydrogen

MAN said its turbocharged E3262 LE202 and naturally aspirated E3262 E302 stationary gas engines are designed for a hydrogen blending of up to 20% by volume when operated with natural gas. No design modifications are required for either engine, the company said.

On a 20% hydrogen blend, MAN said the naturally aspirated engine achieves a CO2 emissions reduction of 5.7% and an HC reduction of 23.0%. The turbocharged engine sees a CO2 reduction of 11.2% and an HC reduction of 17.4%, along with a 1.2% boost in engine efficiency, MAN Engines said.

MITSUBISHI TURBOCHARGER AND ENGINE AMERICA

Itasca, IL

Website: www.det-mitsubishi.com; www.mtea-us.com

Power Range

Diesel: 7.2 to 2923 hp

Gaseous Fuel: 603 to 2011

Marine Engines

While manufacturing and logistics have created delivery delays in almost every marketplace, Mitsubishi said it’s not the case concerning its marine propulsion engines manufactured in Sagamihara, Japan. For many years, the company has taken steps to avoid logistic delays and said it has positioned itself to handle the interruptions resulting from COVID-19’s impact on the world.

Mitsubishi Turbocharger and Engine America has made it a standard practice to inventory significant quantities of marine propulsion engines in its Seattle warehouse and, as a result, the company said it has large inventory levels of Mitsubishi Marine Tier 3 and Tier 4 replacement engines available for immediate delivery.

The company said its heavy-duty marine propulsion engines typically offer bigger displacements and mechanical controls that provide high reliability on the water without the complexities of computer-driven service.

Within the U.S., Mitsubishi offers a range of heavy-duty EPA-certified engines from 429 to 1676 hp. The company said it also has products for Canada and other segments of the Americas where IMO engines are required. The company is supplying its larger SU class engines, rated from 900 to 4000 hp, into South America for tug, pushboat and fishing vessel applications, with the first SU engine recently installed in a fishing vessel in Argentina.

Small Diesels

Mitsubishi’s small L and SL range of EPA Tier 4 diesel engines incorporate mechanical/electronic governors and atmospheric pressure sensors, while EU Stage 5 engines are supplied with mechanical governors. The company’s small diesel engine line includes:

- L2E constant speed engine: Rated 6.9 hp at 1800 rpm, the 0.635 L engine meets Tier 4 Final standards with a mechanical governor, the company said.

- L3E variable/constant speed engines: The 0.952 L diesel is rated 16.8 hp at 2400 rpm, while the L3E constant speed unit is rated 12 hp at 1800 rpm.

- S3L2 variable/constant speed engine: A 1.319 L diesel, its variable rating is 24.6 hp at 2500 rpm, while the constant speed rating is 19 hp at 1800 rpm.

- S4L2 constant speed engine: A 1.50 L diesel rated 24.6 hp at 1800 rpm.

- D03CJ variable speed engine: Rated 36 hp at 2500 rpm, the turbocharged and charge-air-cooled 1.655 L diesel incorporates common rail fuel injection, a diesel particulate filter and a DOC with no EGR.

- 3.331 L D04EG variable speed engines: Available in a naturally aspirated rating of 48.2 hp and a turbocharged output of 72.4 hp, both at 2250 rpm, these engines use EGR along with common rail fuel injection and a DOC.

- D03CJ engine: At 1.655 L, it has a smaller displacement and higher output (36 hp) than the Tier 3 versions, along with 16% better fuel economy than the earlier SQ Series engines.

- D04EG constant speed engine: A 3.3 L unit rated 85.8 hp at 1800 rpm that meets Tier 3 Stationary Emergency Use standards with a mechanical governor.

Natural Gas Engines

Mitsubishi’s natural gas Miller-cycle engine lineup offers outputs from 450 to 1500 kWe at operating speeds of 1200 rpm for extra longevity and efficiency. The engines are equipped with two-stage intercoolers that improve thermal efficiency by 10% over single-stage intercooled engines, the company said, with the 450 kWe, six-cylinder GS6R2 30 L engine delivering an efficiency of 42%.

Tailored for power generation and CHP applications, Mitsubishi said the GSR engines combine advanced lean-burn pre-chamber combustion technology, custom-matched Mitsubishi turbochargers and in-house developed control system. Selected models offer 0.5g/kWh NOx emission capability without SCR and 85% total efficiency in combined heat and power (CHP) applications.

NAVISTAR

Lisle, IL

Website: www.navistar.com

Navistar’s updated A26 engine. (Photo: Navistar)

Navistar’s updated A26 engine. (Photo: Navistar)

Power Range

Diesel: 350 to 516 hp

Diesel Engines

Navistar has made significant updates to its International A26 engine, which the company said allows fleets to achieve 10% improved fuel economy since the engine’s initial launch in 2016. Previous design and system updates account for a 6% fuel efficiency improvement, while the latest engine enhancements to the A26 provide an additional 4% fuel economy benefit, the company said.

The International A26 is a 13 L built from the MAN D26 engine platform. It is available in ratings up to 515 hp with 1850 lb.-ft. of torque.

Engine updates include:

- Combustion enhancements: An increased compression ratio from 18.5:1 to 20.5:1 delivers higher combustion efficiency, along with 36000 psi (2500 bar) fuel injection pressure from a high-pressure common rail fuel system.

- Optimized temperature control: Navistar said the efficient design of the cylinder head coolant passages helps to reduce parasitic loss at the water pump, as well as the addition of a variable water pump provides more optimized run time versus constant “on.”

- Air management updates: An optimized EGR cooler and intake throttle valve create more efficient charge-air flow, the company said. Additionally, a variable geometry turbocharger is designed to deliver the desired boost air pressure across a wide range of engine speeds, loads and elevation.

- The A26 engine is available in the International LT Series of long-haul vehicles, RH Series of regional haul vehicles, HX Series for heavy-haul and various construction applications and HV Series for select vocational applications.

ORIGIN ENGINES

Kearney, NE

Website: www.OriginEngines.com

Origin’s gas engine long block. (Photo: Origin Engines)

Origin’s gas engine long block. (Photo: Origin Engines)

Power Range

Gaseous Fuel: 35 to 670 hp

LPG: 35 to 280 hp

Gasoline: 35 to 174 hp

New Engines

Origin Engines has introduced an inline four-cylinder 3.6 L engine into its lineup. The new engine will be offered in natural gas, propane and gasoline configurations and will bookend the company’s existing portfolio of industrial engines that includes 4.3, 5.7, 6.2, 8.0, 9.1, 10.3 and 24 L displacements. The engines are available in naturally aspirated or turbocharged versions for gasoline, LP, natural gas and wellhead gas. Origin’s products are EPA emissions certified for prime power and standby applications.

In addition to releasing the 3.6 L engine, Origin will also be introducing a new 24 L, V12 engine into the marketplace. The engine is the first product to market since the announcement of an exclusive distribution agreement between Kirloskar Americas and Origin Engines. Origin will gasify Kirloskar’s 16 L V8, 20 L V10 and 24 L V12 diesel engines, providing Origin with a heavy-duty gasified product line rated up to 500 kWe.

Origin’s engine products are manufactured in the U.S. and engineered specifically for industrial use. The company’s products are utilized in a broad range of prime and standby power generation, oil & gas, agricultural pumping, forestry equipment, industrial power unit and mobile industrial applications.

Corporate News

This year, Origin will mark its 40th year of engine manufacturing and will also complete a 60000 sq. ft. expansion project that expands the company’s manufacturing facility by 40%.

PERKINS

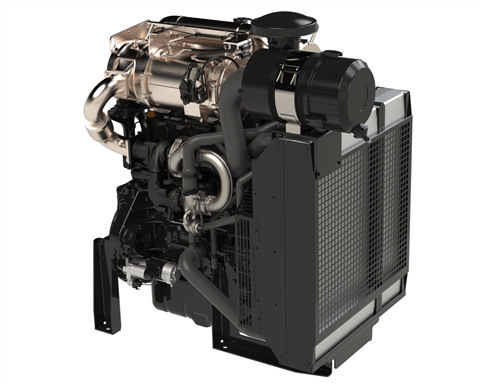

Perkins’ 3.6 L Industrial Open Power Unit. (Photo: Perkins)

Perkins’ 3.6 L Industrial Open Power Unit. (Photo: Perkins)

Peterborough, U.K.

www.perkins.com

Power Range

Diesel: 5.3 to 2927 hp

Power Units

Perkins has expanded its Industrial Open Power Unit (IOPU) offering with the introduction of new 2.8 and 3.6 L models. Part of the Perkins 904 Series family, the IOPUs are engineered to provide equipment manufacturers in the agricultural and industrial sectors with access to plug-and-play power solutions that meet EU Stage 5, and EPA Tier 4 Final emissions standards.

The turbocharged 2.8 L delivers up to 74 hp, while the 3.6 L turbocharged aftercooled offering has a maximum 134 hp output. As with all Perkins IOPUs, the 2.8 and 3.6 L units are highly integrated and ready to plug into a variety of machines, removing the need for extensive reengineering or design. The latest members of the 904 Series range are pre-installed with the electronic control module (ECM), aftertreatment sensors and fuel filter compatible with a wide range of machine types. For reliable cooling performance, a fully integrated cooling package has been validated to operate in a range of territories, and to reduce the installation cost, the aftertreatment is fully engine mounted.

Service

Perkins has launched a new personalized and flexible support program that will be delivered through its distribution network. Perkins Hypercare combines major service elements into a single service package that can include genuine parts, oil, coolant, fluid sampling, engine inspections, preventive maintenance and the Perkins Platinum Protection extended warranty in a single support agreement. Hypercare goes beyond a traditional Customer Service Agreement by offering flexibility in a package designed to optimize and extend the productive life of an engine, Perkins said.

Perkins Hypercare monitors engine status to identify opportunities to add value through service changes and additions while still providing necessary routine service and maintenance functions. Hypercare plans are available in industry-specific core service frameworks for Industrial and Agricultural/Construction/Material Handling and Electric Power.

Perkins is also equipping rental company technicians with a powerful new tool, enabling them to more confidently identify and service Perkins-powered machines in their fleets, through its web-based Rental Support Portal. The updated site provides easy and quick access to Perkins Vision – a series of step-by-step instructional videos for technicians – as well as basic engine maintenance guides, complex diagnostic procedures, exclusive technical information and numerous training modules.

Free for rental technicians enrolled in the Perkins Rental Support Program, , Perkins said the website can be easily viewed and navigated on almost any device, whether it’s a mobile phone, smart tablet or desktop computer.

POWER SOLUTIONS INTERNATIONAL

Wood Dale, IL

Website: www.psiengines.com

Power Range

Diesel: 962 to 1919 hp

Gasoline: 34.1 to 246.7 hp

Gaseous Fuel: 34.1 to 1926 hp

New Engines

PSI recently introduced a new 8.8 L, rich-burn natural gas engine to its lineup, the first since announcing a partnership with Moteurs Baudouin, the French manufacturer of marine and power generation engines.

With an output of 200 kWe, the 8.8 L engine’s power is exceptional for a natural gas engine, PSI said. The engine produces 100% more power than the naturally aspirated variant of the same engine displacement and 60% more than the turbocharged engine variant. It also produces 33% more power than turbocharged and charge-air-cooled engine variants of the same displacement, the company reported.

Emissions

PSI recently received certification from the EPA and California Air Resources Board (CARB) for its 6.0 L gasoline-powered industrial mobile engine. The certification covers mobile, non-road emissions regulations for constant speed operation.

The 6.0 L industrial mobile engine is a fully integrated drop-in solution, designed to deliver high power and performance with maximum fuel efficiency. The engine is rated 174 hp at 2900 rpm, with peak torque of 315 ft.-lb. at the same speed.

PSI is expanding its product line beyond engines to include a full range of new energy products. The company is now offering customers in the energy, industrial and transportation sectors an array of new energy solutions, including low-voltage lithium-ion batteries available between 24 and 120 V and high-voltage systems above the 500 V range.

More information will be included in the New Power Progress Yearbook in the July issue of Diesel Progress.

ROLLS-ROYCE SOLUTIONS AMERICA

Novi, MI

Website: www.mtu-solutions.com

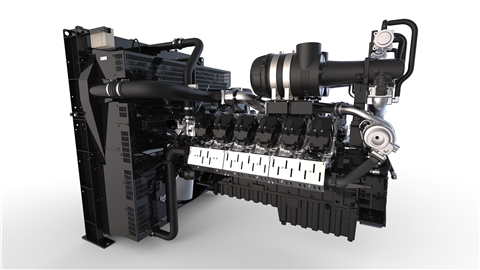

Rolls-Royce’s mtu Series 4000. (Photo: Rolls-Royce Solutions America)

Rolls-Royce’s mtu Series 4000. (Photo: Rolls-Royce Solutions America)

Power Range

Diesel: 100 to 13,410 hp

Gaseous Fuel: 40 to 3487 hp

Hydrogen: 250 to 2514 kWe

Marine Engines

In the second half of 2021, Rolls-Royce launched its mtu Series 2000 propulsion systems for yachts, designed to comply with IMO 3 and EPA Tier 3 recreational regulations using exhaust gas aftertreatment. The engines enable production yachts to sail in protected areas such as in ECAzones, the company said.

In February, the first engines were delivered for installation in a Westport 125 yacht. Rolls-Royce is also delivering its automation solution mtu NautIQ Blue Vision NG for monitoring and control of the yacht’s propulsion system. The 124.6 ft. (38 m) yacht is being built at Westport Yachts’ shipyard in Westport, Wash.

Engine Overhauls

Rolls-Royce Power Systems has introduced significantly extended engine running times of up to 96000 hours between overhauls (TBO) for its latest generation mtu Series 4000 commercial marine engines. All marine engines of the newest generation can now run for up to 25 years before needing a major overhaul, depending on the duration and intensity of use – seven years more between overhauls than previously recommended, the company said.

Alternative Fuels

Rolls-Royce Power Systems said it is investing in methanol technology in efforts to make shipping more climate friendly. New engines will be developed for use in commercial ships and yachts.

In addition, the company has been working to release its most important engine series for use with sustainable fuels such as synthetic paraffinic diesel starting in May 2022, with Series 1600 and 4000 engines for Power Generation and Series 1000, 1100 and 1300 engines for C&I & A. Engines for other applications enabling CO2-optimized and climate-neutral operation will follow by the end of 2023.

Hydrogen

Rolls-Royce said it is further developing its mtu gas engine portfolio for power generation and cogeneration to run on hydrogen and thus enable a climate-neutral energy supply. Within this year, gen-sets powered by mtu Series 500 and Series 4000 gas engines can be operated with a hydrogen content of 25%. Rolls-Royce said it will continuously market new mtu gas engines for use with up to 100% hydrogen and, beginning in 2023, on a design-to order-basis, conversion kits will be available to allow already installed gas engines in the field to run on 100% hydrogen.

Corporate Developments

Rolls-Royce is making a $17.4 million investment at its mtu Aiken manufacturing facility in Graniteville, S.C., for the addition of a new Remanufacturing and Overhaul Regional Center. The 109000 sq.ft. expansion project will provide dedicated and streamlined remanufacturing and overhaul operations to support growth based on customer demand.

In October, Rolls-Royce marked the 25th anniversary of its mtu Series 2000 and Series 4000 engines. The engines have been used in mobile, stationary and marine applications and more than 100000 engines have been sold, amassing over 320 million operating hours.

SCANIA U.S.A.

Scania’s new 13 L pleasure craft engine. (Photo: Scania U.S.A.)

Scania’s new 13 L pleasure craft engine. (Photo: Scania U.S.A.)

San Antonio, TX

Website: www.scaniausa.com

Power Range

Diesel (Industrial): 275 to 770 hp

Diesel (Marine): 220 to 1150 hp

Industrial Diesels

Scania has developed a range of EPA Tier 4 Final and EU Stage 5-compliant, 9, 13 and 16 L industrial diesel engines. The 9 L engines span an output range of 275 to 400 hp, the 13 L engines deliver 350 to 550 hp and the 16 L engine offer ratings from 550 to 770 hp. The engines are found in a variety of North American applications, including stationary, construction, material handling, agriculture, forestry and airport products.

Scania’s Tier 4 Final power generation engines consist of 9 L (208 to 240 kWe), 13 L (264 to 328 kWe) and 16L (320 to 400), all rated for 60 Hz prime power applications.

The company’s engine management system and emissions control technology is designed to provide customized performance and long-term operating economy. Scania currently offers engine versions that meet EPA Tier 4 Final and EU Stage 5, 4, 3A and 2 for industrial applications.

Marine Engines

Scania recently launched new 13 L and 16 L pleasure craft engines. The engines build upon Scania’s modular system, combining the company’s XPI fuel system, engine internals and blocks intended for commercial durability and longevity to result in engines that can reach up to 1150 hp.

The DI13 304M engine spans an extensive power range from the entry level 700 hp to the newest 900 hp rating (925 hp for export). The V8 DI16 carries the output range from 1000 hp to 1150 hp. The simplicity of a single waste-gated turbo per bank, at this power level, translates into reliability and dependability without the need for overly complex twin turbo, multi-stage turbo or supercharged/turbocharged systems, Scania said.

SIEMENS ENERGY ENGINES S.A.U.

Zumaia, Spain

Website: www.siemens-energy.com/gas-engines

Power Range

Diesel: 250 to 1800 hp (marine)

Gaseous Fuel: 252 to 2770 hp

Hydrogen: 338 to 1430 hp (H2 blends up to 50%)

New Engines

Siemens Energy Engines said it is developing a new EPA-certified gaseous fuel engine family for prime and standby power generation applications. The new engines will be available in a power range of 710 to 1540 hp and will be able to accept loads 10 seconds after startup.

The company said it is also completing its SM family of propane engines with a new 1430 hp model. The engine line, which begins at 368 hp, is optimized for power generation and CHP applications in 50 Hz and 60 Hz markets.

Engine Updates

Siemens Energy Engines said it has developed a new fast-start feature for its 1380 and 1460 hp SGE 56SL engines for 50 Hz applications. The T30 option allows the engine to ramp up to full load in less than 30 seconds when starting from zero. The operation includes startup and speed stabilization, grid synchronization, switch closure and load ramp to 100% operating in parallel to grid.

The company has also developed a high-power version of its SGE 56HM engine in 50 Hz applications for both parallel to grid and island mode operation. The engines deliver 1810 hp for paralleling and 1720 hp for island mode using natural gas, sewage and landfill gas.

Engine Technology

Siemens has developed an on-engine fuel blending system designed to allow dynamic blending of natural gas and biogas as a standard, factory-designed and supplied option for gas engines. Integrated into the engine controls, the system maintains a constant output from the engine, irrespective of variations in biogas availability, and ensures consistent energy supply even if biogas production falls to zero, the company said.

The system can seamlessly switch from 100% of one fuel to 100% of another or any combination in between, while maintaining 100% power output, Siemens said. The system was developed for SGE-SL (335 to 1430 hp) and SGE-HM (695 to 1810 hp) engines operating at 1200,1500 and 1800 rpm.

Siemens has also created a series of Modernization and Upgrade kits to update existing engine models in field. These can be used to increase the engine’s output, improve emissions and change the amount of heat available from the cooling circuits.

Hydrogen

Siemens Energy Engines has a product line specifically designed to work with synthesis gases with a hydrogen gas content of up to 40%. The company’s extensive experience, with more than 20 years of working with synthesis gases, has allowed it to establish a clear line toward developing a new product exclusively designed and optimized for H2 fuel.

The current configuration of Siemens Energy natural gas engines enables mixtures with up to 15% hydrogen to be used while retaining engine performance, the company said. Additional changes will allow them to work with up to 50% hydrogen, with only slight changes in engine output compared to conventional natural gas engines.

Taking the configuration of the natural gas engine as the starting point, Siemens Energy Engines is working on improving the internal engine configuration, optimizing both the combustion chamber and the combustion cycle to obtain the best results with up to 20% hydrogen. For installed gas engines in the field that would like to operate with hydrogen fuel mixtures, Siemens Energy Engines said it is simultaneously working on the creation of the adaptation kits.

VOLVO PENTA OF THE AMERCAS

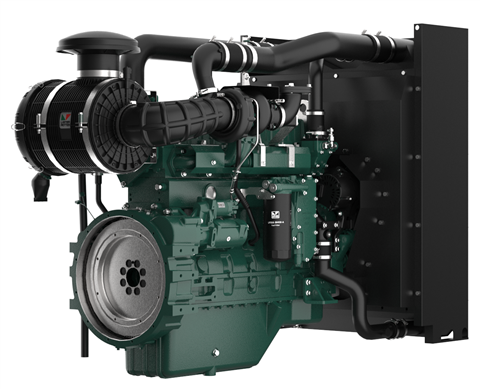

Volvo Penta’s D8 gen-set engine. (Photo: Volvo Penta)

Volvo Penta’s D8 gen-set engine. (Photo: Volvo Penta)

Chesapeake, VA

Website: www.volvopenta.com/en-us/

Power Range

Industrial: 143 to 700 hp (Tier 4 Final)

Diesel: 13 to 1000 hp (marine)

Gasoline: 200 to 430 hp (marine)

Industrial Engines

Volvo Penta offers a wide range of solutions for industrial off-road and power generation applications in North America, leveraging the close working relationship with the technology resources of the other companies in the Volvo Group.

Volvo Penta’s off-road Stage 5/Tier 4 Final D16 was named the Engine of the Year Above 175 hp at the Diesel Progress Summit. The judges stated that the decision was based on the dual-stage turbo system with a water-cooled charged-air system to ensure boost temperatures stay stable and low. They also acknowledged its extraordinary fuel efficiency and lower emissions using an SCR-based exhaust aftertreatment system with no diesel particulate filter, eliminating shutdowns for regeneration.

Volvo Penta said its new D8 Stage 2 and Stage 3/Tier 3 D8 gen-set engines have made inroads in the North American power generation market due to their power density and small size. They are proving to be very popular choices for OEMs, with their reliability, low cost of ownership, quick and compact installation, ease of maintenance and low-noise and vibration-free operation, the company said.

Commercial Marine Engines