Read this article in Français Deutsch Italiano Português Español

Aerial lift makers adopt hydrogen power sources

11 January 2025

Haulotte’s HS18 E PRO scissor lift is powered by a hydrogen fuel cell. (Photo: Haulotte)

Haulotte’s HS18 E PRO scissor lift is powered by a hydrogen fuel cell. (Photo: Haulotte)

Hydrogen fuel cells are used across a diverse cross-section of vehicles and equipment. They are gaining traction in Class 8 trucks, becoming popular in material handling applications and starting to make inroads in construction equipment.

Now it seems access equipment OEMs have joined the roster of equipment makers availing themselves of hydrogen to decarbonize. These include giants like Haulotte, Niftylift and Manitou, each of which has taken a different approach to powering its equipment with hydrogen.

Hydrogen Range Extender

In June 2022, France’s Haulotte signaled the start of its journey to adopt hydrogen energy by announcing a collaboration with Bouygues Energies & Services, a subsidiary of Bouygues Construction. Bouygues then acquired hydrogen solutions specialist Equans in October of that year.

Haulotte’s HS18 E PRO scissor lift was used for the first time at the Saint-Cyr-l’École military school near Paris in October 2024. (Photo: Haulotte)

Haulotte’s HS18 E PRO scissor lift was used for the first time at the Saint-Cyr-l’École military school near Paris in October 2024. (Photo: Haulotte)

Benoît Baleydier, project manager at Haulotte, said the company decided in 2018 to electrify all its machines.

“The electric HS18 E was launched in 2021 from what was historically a diesel machine,” he said of the scissor lift. “We had a removable diesel range extender.”

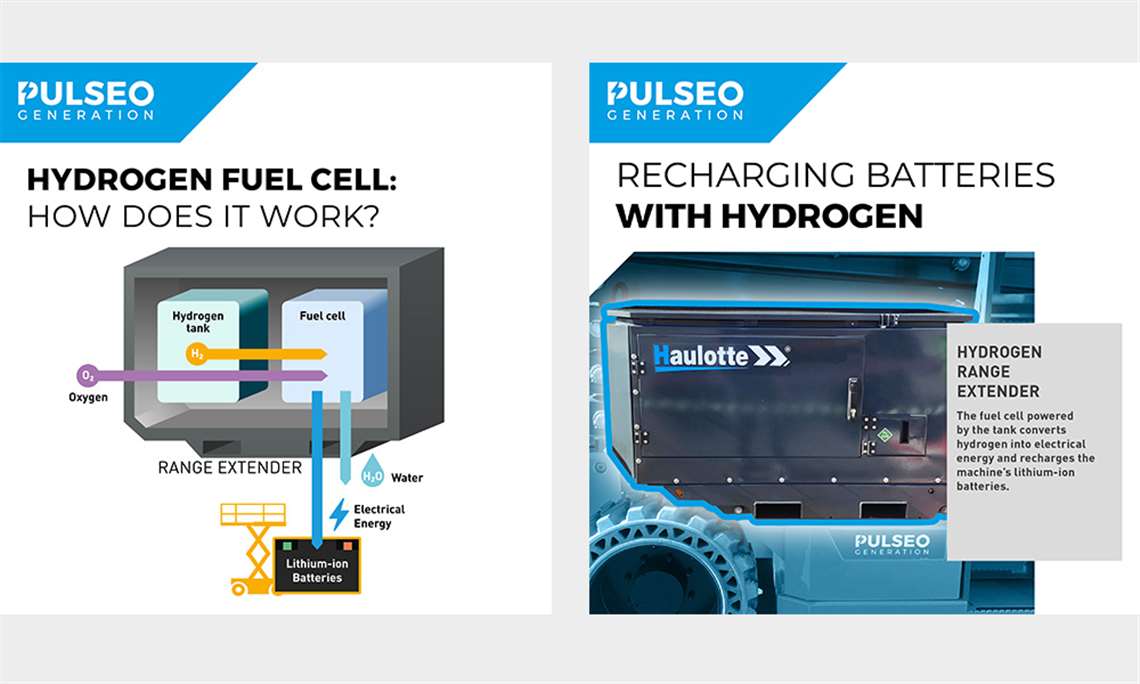

The range extender is a generator that can recharge a scissor lift’s battery to 80 percent in three hours, according to Haulotte’s website. Baleydier said that due to the partnership with Bouygues, the diesel model can now be replaced with a hydrogen fuel cell range extender of the same size and capacity.

October 2024 saw the new hydrogen range extender used for the first time on a jobsite in the Haulotte rough-terrain HS18 E PRO scissor lift at the Saint-Cyr-l’École military school near Paris. Equans is supplying hydrogen for the project, which began in May 2024.

Hydrogen Hurdles

“Technically speaking, hydrogen fuel cell technology is mature,” Baleydier said, “but today’s regulations are not mature enough. Today, we only deal with the regulations for one machine prototype and construction site. But we cannot deal with the regulations for tomorrow’s mass production because they are too complicated.”

Haulotte’s hydrogen fuel cell range extender. (Credit: Haulotte)

Haulotte’s hydrogen fuel cell range extender. (Credit: Haulotte)

Regulators must update current regulations and safety guidelines for storing hydrogen on construction sites before it can be used effectively, he said.

That’s not the only obstacle. Baleydier added that from an economic point of view, hydrogen fuel cell technology is too expensive to justify its use more broadly.

“We are now working with several suppliers to find out how to reduce the costs of this technology,” he said, adding that Haulotte hopes to reduce costs during 2025.

“We want to be sure we will be ready for the future, so we launched this project to check the regulations, technical issues and market response,” Baleydier said.

Refueling Challenges

Nonetheless, Baleydier said that Haulotte customers have marveled at how a diesel-powered range extender could be replaced by a hydrogen-fueled equivalent. The only challenge customers have noted is in refueling time.

“They told us that this [refueling time] is acceptable for an experiment, but we need to improve the refueling system for mass production and daily use,” Baleydier said.

Regulatory constraints led Equans to develop the refueling system without an intermediate tank. Baleydier said refueling will be faster once the hydrogen can be pressurized in advance from 200 to 400 bar and stored in an intermediate tank at 350 bar.

Removable Hydrogen Tanks

Haulotte had considered removable hydrogen tanks for its range extender, Baleydier said, but the company chose not to pursue this because it would require qualified staff to frequently change the tanks.

Niftylift’s hydrogen fuel cell-powered boom lift HR15 uses G20 hydrogen cylinders for refueling. (Photo: Niftylift)

Niftylift’s hydrogen fuel cell-powered boom lift HR15 uses G20 hydrogen cylinders for refueling. (Photo: Niftylift)

However, when UK-based rental firm Speedy Hire and mobile elevated work platform (MEWP) maker Niftylift launched the HR15E and HR17E hydrogen fuel cell-powered access platforms, they chose to use G20 hydrogen cylinders for refueling.

“We use removable tanks,” said Tom Hadden, technical sales manager at Niftylift, of the HR15E and HR17E. “Once you’ve depleted the cylinder, you can change it like a gas barbecue.”

According to Hadden, the training required to use the cylinders is not onerous.

“A level of training is required, but it’s not that you have to do a 10-day course on this,” he said. “In competency-based training, you can be trained within a morning.”

Hadden added, “All the connections we use do not involve tooling, as they’re either hand-tied or push-fit connectors. You don’t have to have a mechanical engineering degree to change your cylinder.”

Fuel Cells vs. Combustion

Fuel cells seem to be a more appropriate technology for MEWPs compared to other decarbonization approaches. In the press release announcing the HR15E and HR17E, Speedy said the machines can typically operate for up to five days on a single electric charge, with the hydrogen fuel cell providing significant additional operational range.

Niftylift’s hydrogen fuel cell-powered boom lift HR15. (Photo: Niftylift)

Niftylift’s hydrogen fuel cell-powered boom lift HR15. (Photo: Niftylift)

Furthermore, Hadden said that many engine makers are not planning to build hydrogen combustion engines smaller than 50 to 55 kW, which are larger than necessary for MEWPs.

“This takes us out of that market, as we only use 19 kW engines,” Hadden said. “But then we realized we don’t need it.” This is because unlike other construction equipment that has much higher utilization — digging and moving all day — an access platform only needs enough power to move into a position and go up in the air, where it will stay for perhaps an hour or two.

While Niftylift has ruled out the use of hydrogen IC engines in favor of hydrogen fuel cell technology, challenges to broad adoption remain. These include the aforementioned lack of industry standards coupled with a shortage of fuel cell suppliers.

“We are looking at extending our range in 2025,” he said. “We have spoken to another fuel cell supplier and agreed to do an urban development program.”

Niftylift will require fuel cells having larger capacities to cover its entire self-propelled lift platform portfolio, Hadden said.

Launches at Bauma

Germany’s Bauma trade show will see other access equipment makers introducing hydrogen fuel cell-powered products. For instance, French telehandler and aerial platform OEM Manitou Group said it plans to have something new to show at Bauma.

Manitou unveiled its first prototype hydrogen telehandler in December 2022. (Photo: Manitou)

Manitou unveiled its first prototype hydrogen telehandler in December 2022. (Photo: Manitou)

Manitou introduced its first prototype hydrogen fuel cell-powered telehandler in December 2022. It was based upon an existing model with a 14 m height range. The company has also set up a hydrogen station to test its prototype telehandlers for range and reliability in real-world conditions.

Manitou said it expects production of a hydrogen-powered telehandler by 2026 and will offer its electric and hydrogen ranges side-by-side. By 2030, the company said it aims to have 43 percent of its products be low-emission.

“The green hydrogen sector is gradually becoming more established with the entry of a number of players into this market,” said Julien Waechter, vice president of R&D at Manitou Group.

He added, “All of the aid mechanisms proposed by the different governments will encourage the transition to hydrogen and will speed up the development of the distribution network and ultimately the reduction in the usage costs of our machines using this energy.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM