Read this article in 中文 Français Deutsch Italiano Português Español

An electric APU primer: supporting hotel loads in trucking without IC engines

14 May 2024

Among the various cost and fuel-efficiency challenges on-highway trucking fleets face is idle reduction. On its website, the North American Council for Freight Efficiency (NACFE) said that historically for trucks with sleeper cabs, a large amount of operating time — 45 percent or more — was spent idling the engine. This is often to accommodate hotel loads — electric power required during periods when the operator is not driving the truck. These include air conditioning, which is among the most power-hungry loads but often necessary for operator comfort.

The push toward sustainability, however, has made engine idling a target for regulation in many U.S. states. In March 2023, the American Transport Research Institute (ATRI) published a compendium of idling regulations that said 30 states in the continental U.S. — along with the District of Columbia — had them, with fines for noncompliance ranging from less than $100 to several thousand dollars.

To help address sustainability as well as cost and fuel-efficiency concerns, some fleets are turning to battery electric alternative power units (APU). APUs provide the power necessary for hotel loads.

Three Idle-Mitigation Tactics

Wade Seaburg, chief revenue officer for Reno, Nev.-based Dragonfly Energy, which makes lithium-ion power systems for commercial trucks via its Battle Born Batteries brand, said when the company talks with fleets about its electric APUs, the conversation covers the three existing idle mitigation approaches in use today.

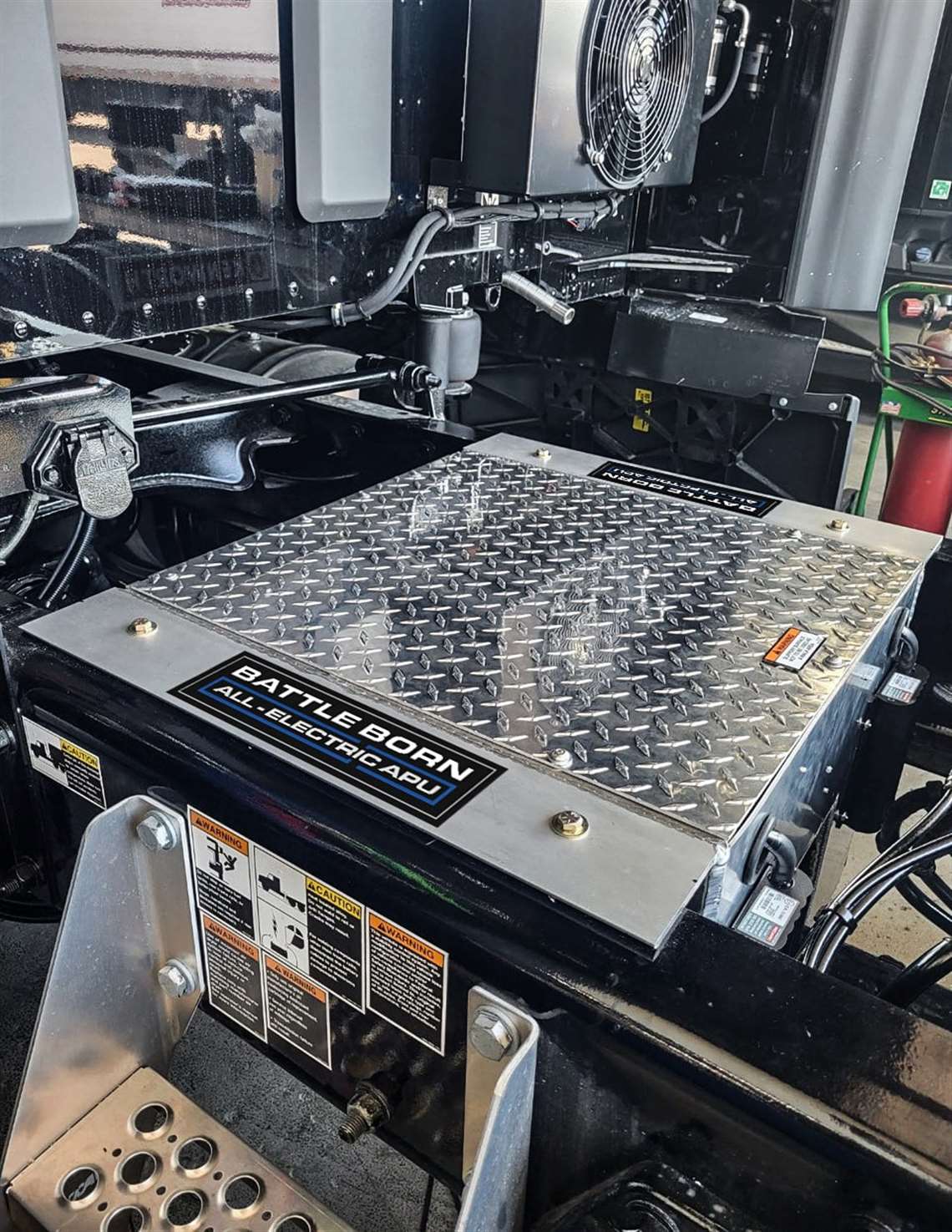

A Battle Born Batteries auxiliary power unit (APU) installed on a heavy-duty truck. (Photo: Dragonfly Energy/Battle Born Batteries)

A Battle Born Batteries auxiliary power unit (APU) installed on a heavy-duty truck. (Photo: Dragonfly Energy/Battle Born Batteries)

“One is simply just deploying an auto stop/start,” he said. “We have an ambient temperature set within the cabin or inside the sleeper berth, and the main diesel engine that’s used for moving freight is going to auto start and stop based on some temperature constraints plus or minus a range.”

Seaburg clarified, saying that if the cabin temperature is preset at 70°F, the engine will start if the temperature goes above 73°F and power the air conditioner until it drops to below 67°F. Then the engine will stop.

He added that in an auto start/stop situation, the truck’s diesel engine consumes about gallon of diesel per hour while also adding wear and tear to other engine components.

“The next step is a diesel APU,” Seaburg said. “That’s going to sip diesel fuel. So, you’re going to burn about a quarter of a gallon per hour.”

While a diesel APU is an improvement over auto stop/start, he said there are drawbacks.

“It has a tendency after about year two to have a lot of mechanical breakdowns, as any kind of small diesel engine might have, so it becomes a bit of a maintenance pain point.”

The third approach, according to Seaburg, is the battery electric APU. He said the operator turn the APU on, and it will power the air conditioner and other hotel loads in the coach “until the battery voltage gets to a certain point or the battery state of charge gets to a certain point, and then the engine will restart” to recharge the battery.

One exception Seaburg noted was in extreme temperatures.

“Fleets are always running the engine if the temperature is above 90°F outside,” he said, “because that 12-volt air conditioner is not capable of cooling it from 90° or 100°F down to a comfortable 70°F for the driver. So they’re still going to idle and run both systems while they’re at that extreme high-end temperature, and then they’re also going to do that when they’re down at freezing temperatures in order to keep all the engine fluids running smoothly.”

Many of the states with engine idling regulations have published temperature exceptions to their regulations. Atlanta, Ga., for instance, restricts engine idling to 15 minutes but extends that to 25 minutes if the temperature is below 32°F.

Seaburg added that because of these temperature-related realities, the sweet spot for battery electric APUs is 20° to 90°F, during which time there is “absolutely no need to run that engine.”

The Right Batteries

Some battery electric APUs make use of absorbed glass mat (AGM) batteries, Seaburg said, adding they are not always the best choice.

“AGMs are good at two tasks,” he said. “They’re good at cranking, and they’re good at deep cycle, but they’re not great at either one of those. They’re low maintenance — they have some pros. But they are being replaced after 18 to 24 months because of how fast they degrade.”

States in the continental U.S. having diesel engine idling regulations, highlighted in red. (Data: American Transportation Research Institute. Graphic: Mapchart.net)

States in the continental U.S. having diesel engine idling regulations, highlighted in red. (Data: American Transportation Research Institute. Graphic: Mapchart.net)

According to Seaburg, only about 15 percent of trucks are ordered with an electric APU because many who have tried them have been underwhelmed with the operational time due to the use of AGM batteries.

“They’re promised 10 hours,” he said. “They only get four, and then as they go, they get less and less.”

Flooded lead acid batteries, while not an option for electric APUs, are better for engine cranking than AGM batteries, Seaburg said. They are also less expensive.

In implementing the Battle Born APU solution, Seaburg said Dragonfly leverages its understanding of battery charging to allow for the use of both battery chemistries on the truck as well as lithium-ion, while ensuring they can all be charged using a single alternator.

“What we do is we dedicate that front bank of, say, three flooded batteries to crank the engine,” Seaburg said. “We put an isolator in there that allows for isolation of the two banks, but it also allows for proper charging of our system. And then we put a lithium system in to run all those same air conditioning and inverter and appliances that you find on the electric APUs today.”

According to Seaburg, Dragonfly’s lithium-ion solution can consistently provide power throughout the duration of a 10-hour rest period.

“We’ve made it through 34-hour restarts when ambient temperature is proper, like in Texas in October, and we’re not running the energy hog — which is that air conditioner — we’re not running that a lot,” he said. “There’s not an AGM battery bank that’s making it through a 34-hour restart period.”

Diesel-Friendly Value

In terms of sustainability and reduced wear and tear, Seaburg said the Battle Born APU is a “friend to the diesel engine.”

“We believe that it [the diesel engine] should be on to move freight where needed, and it should turn off in all other instances,” he said. “It does not need to idle to keep the driver comfortable anymore.”

And while that can help the industry overcome regulatory hurdles, Seaburg said the company’s battery APUs offer additional value.

“Even the regulatory hurdle of ‘don’t idle’ means ‘don’t idle your largely diesel engine,” Seaburg said. “And in some of those jurisdictions, you can still idle that small diesel APU. But our message is don’t even do that. Let’s just turn the engine off altogether. Eliminate the exhaust fumes that maybe that driver’s inhaling. Let’s stop the the hum — let’s make it a quiet environment where they can sleep and they don’t get woken up.”

An electric APU also helps mitigate diesel engine maintenance, according to Seaburg, because when the engine idles, “we’re operating all the other devices that are attached” to it, including the water pump, fuel pump and related seals, which will suffer undue wear and tear.

Finally, Seaburg noted significant improvements in fuel efficiency with the use of the Battle Born APU.

“We’re seeing anywhere form a 10 to 15 percent increase in miles per gallon in fleets that have deployed this,” he said, adding that other tactics for addressing fuel economy, such as side skirts, only yield a fraction of that savings.

“Let’s say you idle for 4 to 5 hours a night,” Seaburg said. “When you’re saving 4 to 5 gallons a night that you’re not having to burn anymore, that’s real dollars.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM