Read this article in Français Deutsch Italiano Português Español

Cummins’ first engine distributor was on the West Coast

18 June 2025

Watson & Meehan’s photos were seen throughout early issues of Diesel Progress.

Watson & Meehan’s headquarters at 1960 Folsom Street in San Francisco. The 34,000 sq.ft. building still stands and was most recently occupied by a robotics company. (Photo courtesy of Cummins Heritage Center)

Watson & Meehan’s headquarters at 1960 Folsom Street in San Francisco. The 34,000 sq.ft. building still stands and was most recently occupied by a robotics company. (Photo courtesy of Cummins Heritage Center)

Application stories were popular features in Diesel Progress, just as they are in today’s Power Progress. During the first two decades following the pubication’s first issue in May, 1935, articles that described the use of diesel-powered machines on construction sites or quarries on the West Coast were usually accompanied by photos supplied by Watson & Meehan. Located in San Francisco, Calif., the company was Cummins Engine Co.’s first engine distributor.

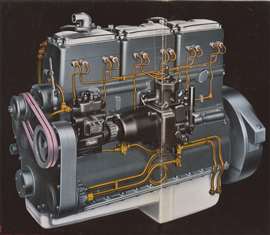

A Cummins Model HB-600 six-cylinder diesel engine rated 150 hp, as shown in an advertisement from 1940. A list of 21 truck companies that were using Cummins diesels sat next to this illustration, including Corbitt, Federal, FWD, Hug, Linn, Marmon-Herrington, Oshkosh, Peterbilt and White Motor Truck Co. (Illustration courtesy of Cummins Heritage Center)

A Cummins Model HB-600 six-cylinder diesel engine rated 150 hp, as shown in an advertisement from 1940. A list of 21 truck companies that were using Cummins diesels sat next to this illustration, including Corbitt, Federal, FWD, Hug, Linn, Marmon-Herrington, Oshkosh, Peterbilt and White Motor Truck Co. (Illustration courtesy of Cummins Heritage Center)

Exactly how the young engine manufacturer came to select a city more than 2,000 miles from its Columbus, Ind., headquarters and factory is a good story about the early days of the engine business. In addition to Clessie Cummins, it includes this cast of characters:

- W.G. Irwin: Born in 1866, he was a prominent Columbus businessman who hired Clessie Cummins as his family’s chauffeur. He supported Clessie’s experiments with internal combustion engines and co-founded Cummins Engine Co. in 1919. Irwin also invested in other businesses, including a chain of grocery stores in California.

- Paris E. Letsinger: Appointed vice president of sales for Cummins Engine Co. in 1933, he was well-known in trucking circles at the time. He had worked for White Motor Co. for 12 years prior to Cummins, eight as San Francisco district manager.

- John Niven: An Indiana businessman and friend of W.G. Irwin, he worked his way up at the Indianapolis-based and Irwin-financed Van Camp Packing Co. before starting Purity Stores in San Francisco. Of the $60,000 capital that launched the grocery store chain, $40,000 came from Irwin. In 1930, Irwin asked Niven to take over the business management of Cummins Engine Co. Niven moved to Columbus while his partner ran Purity Stores. He was elected vice president and general manager of Cummins in April 1932 but returned to California when his partner died. He traveled between Indiana and California until he resigned from the engine company in February 1934 and returned his focus to the grocery store chain.

- Purity Stores Ltd.: The chain of grocery stores founded by Niven in 1925 was said to be among the first with everything under one roof, including meat, canned goods, produce and other household items. The chain opened its 110th location in California in 1929. The company was liquidated by the Niven family in 1972.

Inside Watson & Meehan’s headquarters at 1960 Folsom Street in San Francisco. The now-empty building was available for sublease as of June 18, 2025. (Photo courtesy of Cummins Heritage Center)

Inside Watson & Meehan’s headquarters at 1960 Folsom Street in San Francisco. The now-empty building was available for sublease as of June 18, 2025. (Photo courtesy of Cummins Heritage Center)

Tackling the truck market

For a few years after starting the engine company, Clessie Cummins had an engine in search of a market. Stationary and marine applications were tried before he tested a diesel engine in a retrofitted Packard car. Finally, he took the advice of his friend Henry Ford and focused on developing an engine for trucks.

To gain some experience with the application, Clessie installed a Model U diesel engine into a two-axle Indiana truck made in Marion, Ind., and then he and two other drivers set out on a run from New York City to Los Angeles. In 1931, long before interstates were invented, the trio reached their destination after four days and one hour, having averaged 15.75 mpg across 3,214 miles. That endurance run, as well as others that followed, did as much to establish the Cummins diesel as a truck engine as it did for the automotive diesel engine in general.

Watson & Meehan repowered this Allis-Chalmers Model HD-19 crawler tractor with a Cummins NHS diesel engine rated 275 hp. The owner of the machine was H.E. Parker, a contractor in Marysville, Calif. (Photo courtesy of Cummins Heritage Center)

Watson & Meehan repowered this Allis-Chalmers Model HD-19 crawler tractor with a Cummins NHS diesel engine rated 275 hp. The owner of the machine was H.E. Parker, a contractor in Marysville, Calif. (Photo courtesy of Cummins Heritage Center)

Companies on the West Coast were especially interested in the engine. Niven suggested that Cummins run a commercial test of the power plant using Purity’s fleet of trucks.

In a 1952 memo to Cummins, Mark Ogden, advertising manager for Watson & Meehan (he’d be hired as an editor for Diesel Progress a few years later), included a letter Niven had written earlier about the start of the engine program:

“We knew that practically every operator was convinced of the fact that an automotive diesel would never be perfected and faced that handicap to begin with. Also, we were up against the fact that the gasoline engine had been improved and perfected over a period of 40 years and at the outset an automotive diesel would have to be as practicable and as foolproof as the present-day gasoline engine. It was a hard field in which to attempt to compete.

“It was decided that to so perfect the Cummins Diesel that it would be entirely foolproof and practical, we should confer with truck manufacturers’ engineering departments and find from them what was the present day features most desirable, what was the most desirable horsepower, etc….

“When Clessie and his engineers drew up specifications and plans and the factory proceeded to produce the first Model H engine, almost wholly by hand, thought was given to how it could best be tested without getting the black eye that would naturally result from any failure of a diesel engine which everybody knew wouldn’t successfully run in the first place.

These two Cummins six-cylinder Model L diesel engines were connected to Westinghouse 100 kw generators in December 1939. “Powering the Dan Tucker Mine, owned by the Summit King Mines Ltd…. Located 30 miles southest of Fallon, Nev., virtually on the summit of the pass over 9,000 ft. altitude, is a modern cyanide plant.” (Photo courtesy of Cummins Heritage Center)

These two Cummins six-cylinder Model L diesel engines were connected to Westinghouse 100 kw generators in December 1939. “Powering the Dan Tucker Mine, owned by the Summit King Mines Ltd…. Located 30 miles southest of Fallon, Nev., virtually on the summit of the pass over 9,000 ft. altitude, is a modern cyanide plant.” (Photo courtesy of Cummins Heritage Center)

“It was desired to place it in hard service. Next, it was desired to place it sufficiently far away from the factory that the user could not pick up the telephone and call for some minor adjustment or service at any moment. Up to that time in the marine engine field, engines would leave the factory in running condition, but in the hands of the amateur operator would soon be out of adjustment. There was no place to turn locally to get service, so the factory would receive a frantic telegram to send the service man. That sort of practice would never be practical in the automotive field and we well understood it.

“So it was desired to get the first engine in service into the hands of a friendly operator who would cooperate and who would put up with the difficulties of a new and untried model and that operator should be sufficiently far away from the factory that he would be ‘on his own’ in order that any ‘bugs’ or difficulties which would naturally appear and in the hands of an operator, with a machine shop available, could be serviced locally. If, after an extreme effort in that direction, the operator failed, then a man could be sent from the factory.

“Purity Stores fell within this category. There was a community of interest between the two companies. Distance from a factory was as far away as it was possible to achieve in the continental United States.”

The original caption for this Watson & Meehan photo read, “Calaveras Cement Co., San Andreas, Calif., is making 900,000 barrels of cement going into Folsom Dam. Here are 18 of the company’s 22 Cummins-powered transport trucks. It also operates 12 quarry trucks and a switch locomotive powered by Cummins diesels.” (Photo courtesy of Cummins Heritage Center)

The original caption for this Watson & Meehan photo read, “Calaveras Cement Co., San Andreas, Calif., is making 900,000 barrels of cement going into Folsom Dam. Here are 18 of the company’s 22 Cummins-powered transport trucks. It also operates 12 quarry trucks and a switch locomotive powered by Cummins diesels.” (Photo courtesy of Cummins Heritage Center)

Publicity generator

While working as general manager of Cummins and co-owner of Purity Stores, Niven reached out to Lessinger at White’s office in San Francisco to buy a new White chassis sans engine and transmission. In Columbus, Cummins Engine Co. installed a new Model H diesel engine. The truck was picked up by one of Purity’s fleet drivers on April 27, 1932, and driven to California where a body was installed.

When Purity Stores started using the diesel-powered truck as part of its test program, it generated a lot of interest among other fleet operators. White, Purity and Cummins often had to explain to interested people that what they were seeing was a test engine and installation. It was not yet for sale.

Photographed in March 1940, this is a sugar beet harvester designed and built by John Zuckerman of Weyl-Zuckerman & Co. on McDonald Island, Calif. It was powered by a Cummins Diesel Model HBI-600. The growers used the machine to harvest 825 acres of beets, and it helped them to harvest 400 tons a day with only six people. Without the machine, the same output would have required 75 workers. (Photo courtesy of Cummins Heritage Center)

Photographed in March 1940, this is a sugar beet harvester designed and built by John Zuckerman of Weyl-Zuckerman & Co. on McDonald Island, Calif. It was powered by a Cummins Diesel Model HBI-600. The growers used the machine to harvest 825 acres of beets, and it helped them to harvest 400 tons a day with only six people. Without the machine, the same output would have required 75 workers. (Photo courtesy of Cummins Heritage Center)

Purity Stores promoted its one diesel truck heavily during 1932. Press releases were sent to local newspapers whenever the Cummins diesel visited one of the chain’s stores. On June 9, 1932, for example, the Porterville (Calif.) Recorder said, “Garage owners, garage mechanics and students of the mechanics department of the high school were guests today of Purity Stores, who brought the first diesel engine into Porterville that has ever come into the city. The diesel engine operates a truck of 26 tons capacity, developing 175 hp, and is the most powerful truck ever built. The truck remained here for several hours in front of the Purity store and was the center of interest of a large crowd of people.”

As soon as it was possible to do so, other fleets began ordering trucks powered with Cummins diesel engines. By the end of the year, six American manufacturers were offering truck models powered by four- and six-cylinder Cummins diesels. The pioneering Indiana truck maker was soon joined by Gramm, Gotfredson, Sterling, LeMoon and Kleiber. The trucks were rated from 3 to 18 tons.

Purity Stores placed another four diesels on the road later in 1932. Within a year, the five trucks had logged 219,899 miles. They averaged 7.1 mpg, as compared to 3.34 mpg for comparable gasoline engines.

By 1952, the Purity fleet consisted of 31 Cummins diesel trucks, all made by Peterbilt.

Mark Ogden photographed this Freightliner on U.S. Highway 95 outside of Winnemucca, Nev. “I hope this will prove to be a magazine cover,” he wrote on his Field Trip Report for July 12, 1954. The focus was DeLong Truck Lines of Winnemucca. “Emmet DeLong started in the trucking business in 1926 with a hard-tired Paige truck. He hauled general freight. Last spring DeLong bought a cab-over engine sleeper White Freightliner from Sierra Truck and Trailer in Reno. He traded in his Kenworth cattle rig powered by a 200 hp Cummins diesel. The Model WF64 dual-drive Freightliner is powered by a 275 hp Cummins diesel. While DeLong Truck Lines hauls general freight, it specializes in the transportation of livestock. He hauls ‘fat stuff’ to market in San Francisco. Feeders are hauled to ranches throughout Idaho, Oregon, Nevada and California. DeLong’s [1948 Diamond T powered by a 275 Cummins diesel engine] spent 16 consecutive days this spring hauling bands of sheep into the Ruby range of mountains [near Elko, Nev.] from winter ranches. A ‘band’ of sheep consists of 1500 ewes and 1500 lambs.” (Photo courtesy of Cummins Heritage Center)

Mark Ogden photographed this Freightliner on U.S. Highway 95 outside of Winnemucca, Nev. “I hope this will prove to be a magazine cover,” he wrote on his Field Trip Report for July 12, 1954. The focus was DeLong Truck Lines of Winnemucca. “Emmet DeLong started in the trucking business in 1926 with a hard-tired Paige truck. He hauled general freight. Last spring DeLong bought a cab-over engine sleeper White Freightliner from Sierra Truck and Trailer in Reno. He traded in his Kenworth cattle rig powered by a 200 hp Cummins diesel. The Model WF64 dual-drive Freightliner is powered by a 275 hp Cummins diesel. While DeLong Truck Lines hauls general freight, it specializes in the transportation of livestock. He hauls ‘fat stuff’ to market in San Francisco. Feeders are hauled to ranches throughout Idaho, Oregon, Nevada and California. DeLong’s [1948 Diamond T powered by a 275 Cummins diesel engine] spent 16 consecutive days this spring hauling bands of sheep into the Ruby range of mountains [near Elko, Nev.] from winter ranches. A ‘band’ of sheep consists of 1500 ewes and 1500 lambs.” (Photo courtesy of Cummins Heritage Center)

Cummins’ first distributor

All of the attention by truckers on the West Coast – so far from Columbus – required a strategy for service and support. In San Francisco, a dealer of truck drivetrain components, Howard S. Watson, took on sales and service for the new engines. Watson was busy with his original business so he hired Richard P. Meehan to handle sales. Within a few months, he had purchased an interest in the firm.

It was 1933, and Watson & Meehan was born. The firm operated under that name until February 1, 1981, when it became Cummins West Inc.

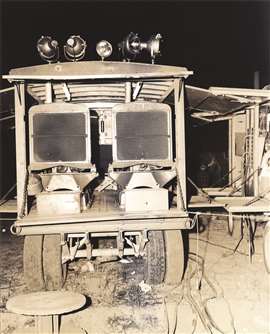

On August 29, 1951, Mark Ogden visited the Ringling Bros. and Barnum & Bailey circus. “I accompanied Rodger Doxsey of the [Cummins] factory…to look over some of the Cummins-powered equipment belonging to the circus. A salesman had the Crown Graphic camera on the road so it was only possible to take Kodachrome pictures. Ringling Bros. has 13 Cummins engines on the road with them this season and own at least one more which was left at the winter quarters in Sarasota, Fla. Two Model HIP-800 Cummins Engines are in a portable generator unit, each attached to generators. The engines run at 1,200 rpm, have Woodward governors, and produce approximately 76 hp. Combined, the generators produce 120 kw direct current. This electricity is used to light the sideshow, ticket wagons, etc. The circus does not have any Diesel mechanics as such, and the engines are not given a great amount of expert attention.” (Photo courtesy of Cummins Heritage Center)

On August 29, 1951, Mark Ogden visited the Ringling Bros. and Barnum & Bailey circus. “I accompanied Rodger Doxsey of the [Cummins] factory…to look over some of the Cummins-powered equipment belonging to the circus. A salesman had the Crown Graphic camera on the road so it was only possible to take Kodachrome pictures. Ringling Bros. has 13 Cummins engines on the road with them this season and own at least one more which was left at the winter quarters in Sarasota, Fla. Two Model HIP-800 Cummins Engines are in a portable generator unit, each attached to generators. The engines run at 1,200 rpm, have Woodward governors, and produce approximately 76 hp. Combined, the generators produce 120 kw direct current. This electricity is used to light the sideshow, ticket wagons, etc. The circus does not have any Diesel mechanics as such, and the engines are not given a great amount of expert attention.” (Photo courtesy of Cummins Heritage Center)

During the 1950s, Watson & Meehan Advertising Manager Mark Ogden traveled extensively throughout the West with a large format Crown Graphics camera and a notebook, documenting users of Cummins-powered equipment as well as potential customers of Watson & Meehan. No doubt Ogden was behind most of the Watson & Meehan photos that ran in Diesel Progress.

A large collection of scrap books and original photos wound up in the files of Walter McCarthy, who was hired as the fourth employee of Watson & Meehan in 1937. He was eventually elected president, a position he held until he retired and sold the company in 1981. The photos are now preserved by the Cummins Heritage Center, thanks to archivist Lori Lindberg.

Mark Ogden’s Field Trip Report No. 119 from March 4, 1953, focused on Devine and Sons Trucking Co. of Sacramento, Calif. The trucking company hauled lumber, grain and had a contract to haul plate steel into the Folsom State Prison. “Devine owns 12 Cummins Diesels, seven 200 hp, four 165 hp and one spare 150 hp. J.J. Devine Sr. says he was the first Cummins owner in the country, and one of the first in the West after Purity Stores had test-proved the engine. Nearly 20 years ago, in the summer of 1934, Mr. Devine bought two Cummins Diesels under these circumstances. He was operating a Fageol [truck] with a four-cylinder gasoline engine. He was having all kinds of trouble with the engine and the engine’s dealer agreed it was not the right engine. They said they would take the engine back and give him a good allowance if he would buy two six-cylinder engines [of the same make]. He was ready to do this… ‘when Dick Meehan walked in. I told him what I was going to do, and he offered to take the gasoline engine in if I would buy two Cummins Diesels. I took him up, and I’m convinced today that that transaction kept me from going broke. If I’d have bought those big gas engines, I couldn’t have paid the fuel and repair bills. Even today, I don’t see how truckers stay in business driving any other kind of engine.’ Later, Devine said he got sore at Watson & Meehan because he couldn’t get a fleet discount on his purchases. ‘I was probably wrong,’ he said. Anyway, he pulled a 150 hp Cummins out of a Peterbilt and installed a Buda 215 hp. It was down so much of the time and burned so much more fuel than this 200 hp Cummins Diesel that he repowered it with a 200 hp Cummins.” (Photo courtesy of Cummins Heritage Center)

Mark Ogden’s Field Trip Report No. 119 from March 4, 1953, focused on Devine and Sons Trucking Co. of Sacramento, Calif. The trucking company hauled lumber, grain and had a contract to haul plate steel into the Folsom State Prison. “Devine owns 12 Cummins Diesels, seven 200 hp, four 165 hp and one spare 150 hp. J.J. Devine Sr. says he was the first Cummins owner in the country, and one of the first in the West after Purity Stores had test-proved the engine. Nearly 20 years ago, in the summer of 1934, Mr. Devine bought two Cummins Diesels under these circumstances. He was operating a Fageol [truck] with a four-cylinder gasoline engine. He was having all kinds of trouble with the engine and the engine’s dealer agreed it was not the right engine. They said they would take the engine back and give him a good allowance if he would buy two six-cylinder engines [of the same make]. He was ready to do this… ‘when Dick Meehan walked in. I told him what I was going to do, and he offered to take the gasoline engine in if I would buy two Cummins Diesels. I took him up, and I’m convinced today that that transaction kept me from going broke. If I’d have bought those big gas engines, I couldn’t have paid the fuel and repair bills. Even today, I don’t see how truckers stay in business driving any other kind of engine.’ Later, Devine said he got sore at Watson & Meehan because he couldn’t get a fleet discount on his purchases. ‘I was probably wrong,’ he said. Anyway, he pulled a 150 hp Cummins out of a Peterbilt and installed a Buda 215 hp. It was down so much of the time and burned so much more fuel than this 200 hp Cummins Diesel that he repowered it with a 200 hp Cummins.” (Photo courtesy of Cummins Heritage Center)

This article originally ran in the 90th anniversary issue of Power Progress, published in May 2025.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM