Read this article in Français Deutsch Italiano Português Español

Engine makers bringing innovation to Munich

27 March 2025

While finished equipment — electrified and driven by alternative power — will be the highlight of Bauma 2025, so will engine technology. Many engine-making giants plan on showcasing their latest innovations at the trade fair.

Briggs & Stratton (Hall A2, Stand 349)

Briggs & Stratton said that at Bauma 2025, it plans to showcase its Vanguard engine and battery solutions designed for construction applications. The company said the solutions are adaptable to meet the industry’s evolving needs, and Vanguard is also committed to delivering a lower total cost of ownership (TCO).

Briggs & Stratton will showcase Vanguard engine and battery solutions at Bauma 2025. (Image: Briggs & Stratton)

Briggs & Stratton will showcase Vanguard engine and battery solutions at Bauma 2025. (Image: Briggs & Stratton)

From an engine perspective, visitors will have the opportunity to explore drop-fit single-cylinder engines as well as Big Block gasoline alternatives to diesel.

Vanguard single-cylinder, horizontal-shaft commercial engines have been engineered for power, reliability, and reduced maintenance while being able to withstand tough job site conditions, Briggs said. These engines, including the Vanguard 160, 200, 300, and 400 EFI/ETC models, offer drop-fit solutions designed to meet the demands of construction applications.

The company said the engines offer long maintenance intervals — 200-hour oil maintenance and 600-hour air cleaner maintenance — for reduced downtime and lower TCO. Technologies such as TransportGuard further enhance ROI by minimizing unnecessary and costly oil changes.

Also featured will be Vanguard’s Big Block EFI/ETC 29.9 kW (40 hp) engine as an alternative for high-power applications. These engines deliver the performance needed on construction sites while also reducing fuel consumption and maintenance costs, Briggs said. Vanguard’s electronic fuel injection (EFI) technology also optimizes fuel efficiency.

Cummins (Hall A4, Stand 338)

Cummins said it is set to premiere the new X15 Next Generation at Bauma 2025. This is the latest addition to its range of HELM (high efficiency, lower emissions) fuel-agnostic engines.

Based on an all-new platform, the X15 Next Generation will be presented at Bauma as a diesel engine, but using different heads for each fuel also supports using natural gas (LNG/CNG) or hydrogen. Diesel variants will be capable of using hydrotreated vegetable oil (HVO) to achieve carbon-neutral operation.

Cummins will unveil its X15 Next Generation engine at Bauma 2025. (Photo: Cummins)

Cummins will unveil its X15 Next Generation engine at Bauma 2025. (Photo: Cummins)

The new engine will directly replace the existing X15. But while it will deliver a 15 percent increase in power (444 kW, 605 hp and 2,050 lb. ft., 2,779 Nm of torque), the new platform will have a footprint comparable to a smaller 13L model. This will help reduce the space needed onboard machinery using the powerplant.

The X15 Next Generation will offer the same mounting points whether set up to use diesel, natural gas or hydrogen. This will allow machine OEMs to install any variant without having to reconfigure the engine bay.

According to Cummins, use of over-the-air programming will generate a maintenance schedule suitable for the specific duty cycle. Across the engine, cartridge-style filters simplify maintenance, reducing costs and further minimizing environmental impact.

Additionally, the new X15 has a series of features intended to help reduce fuel consumption, including a redesigned piston bowl and skirt design, plus cooling system optimization that helps restrict flow. In total, the new engine can reduce fuel consumption by up to 7 percent compared to the outgoing model.

Liebherr (Hall A4, Stand 326)

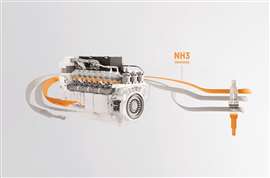

Liebherr said it will unveil three new combustion engine technologies at Bauma 2025. These include the D9612 diesel engine, a hydraulic air boosting system and an ammonia-fueled engine concept.

Liebherr’s combined ammonia fuel engine. (Image: Liebherr)

Liebherr’s combined ammonia fuel engine. (Image: Liebherr)

The D9612 is a 27L V12 that can deliver a maximum power output of 950 kW (1,274 hp). It features an integrated centrifugal water pump, closed crankcase ventilation and an ultrafine fiber oil filter. A twin scroll turbocharger is said to help improve fuel consumption.

Liebherr’s hydraulic air booster will also be on display. This helps to manage engine dynamics during lean mix engine operation. The system is designed to recover hydraulic energy for use with a mechanical compressor.

In addition, Liebherr will present its ammonia-fuel engine concept. The company has been investigating ammonia as a power source for dual-fuel internal combustion engines, with results preparing for further development work. The engine promises the high power density needed to support heavy-duty applications.

A mock-up of the ammonia engine will be on display at Liebherr’s main booth in the Atrium area.

Perkins (Hall A4, Stand 336)

As part of its promise to “deliver smarter solutions to advance sustainable power,” Perkins will highlight its upcoming 2606 engine at the Munich trade fair. The 12.9L, six-cylinder engine will replace the existing 15L and 18L models due to its superior power output and power density, the company said.

Based on the 2600 platform, the 2606 is set to be offered with power outputs ranging from 340 to 515 kW (456 to 690 hp). This equates to about 40 kW (54 hp) per liter of displacement. While delivering more power, the engine is compliant with EU Stage 5, U.S. Environmental Protection Agency (EPA) Tier 4 and all other global emissions standards.

The Perkins 2606 12.9L six-cylinder engine. (Photo: Perkins)

The Perkins 2606 12.9L six-cylinder engine. (Photo: Perkins)

The 2606 can be used across a series of application types, including construction machines and agricultural tractors. While producing the same power output as larger engines, the 2606 has a smaller overall footprint while also being 20 percent lighter. This means the engine requires less onboard space.

The 2600 platform is a “clean sheet” design that has been in development since 2017. The engine was premiered in 2023, and the appearance at Bauma 2025 precedes the engine’s anticipated market launch in 2026.

In addition to showing these and other engine models, Perkins will be releasing more details about its Project Coeus at Bauma. First announced in 2023, the initiative is intended to deliver a power solution capable of supporting a variety of alternative fuels, including ethanol, methanol, biomethanol and hydrogen.

Speaking about the project, Paul Moore, head of Powertrain System Integration at Perkins, said that different injection models will be used to support both gaseous and liquid fuels within a single combustion chamber.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM