Read this article in Français Deutsch Italiano Português Español

Kohler Energy publishes gen-set environmental declaration

28 June 2024

Independently verified document is ‘market-first’ for mission-critical gen-set

The Power Systems segment of Kohler Energy announced publication of a certified environmental declaration for its KD Series generator set, making it the first company to do so for a generating set in mission-critical markets, the company stated.

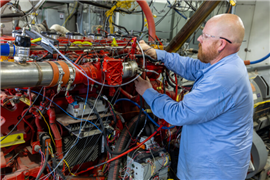

Kohler Energy said it is the first company to publish an environmental declaration for a generating set in mission-critical markets. (Photo: Kohler Energy)

Kohler Energy said it is the first company to publish an environmental declaration for a generating set in mission-critical markets. (Photo: Kohler Energy)

“The publication of the market’s first environmental declaration for a generating set is a crucial step in our long-term sustainability strategy,” said Charles Hunsucker, president of Power Systems at Kohler Energy. “The transparent and standardized information in the document provides mission-critical generator customers with complete visibility about the environmental impact of generators from KD2000 to KD4500 – allowing them to make informed buying decisions as part of low carbon strategies.”

The environmental declaration is a data-driven document published in the form of a PEP ecopassport, a Type III environmental declaration according to the ISO 14025 standard that provides comprehensive information about environmental impact at every stage of the product lifecycle. The environmental declaration has initially been issued for the KD3750-F backup generator as a reference product, with the baseline data to be extrapolated to calculate the environmental impact of other generators in the K175 series family, from KD2000 to KD4500.

While the PEP ecopassport covers generators made in France, Kohler Energy plans to introduce a similar environmental declaration for product made in the US.

According to Kohler Energy, the document provides granular data on the environmental impact of activities such as raw material extraction, manufacture, distribution, installation, use and end-of-life of KD Series generators. The lifecycle assessment methodology saw the company collaborate with key suppliers to collect information on energy consumption, emissions, resource usage and other relevant parameters. The environmental declaration was then verified by independent third parties to ensure accuracy and compliance with standards.

The lifecycle analysis showed that a KD3750-F emergency generator with an internal combustion engine comprises over 94% recyclable metals, and without the use of rare materials like lithium, nickel, manganese or cobalt in the electric batteries, Kohler Energy pointed out. It also cited the environmental benefit of using renewable fuels such as hydrotreated vegetable oil (HVO).

Kohler Energy said the document’s publication is part of a broader sustainability strategy, which includes improving generator efficiency while investing in zero-emissions technologies. For example, the company’s full range of mission-critical diesel generators is compatible with HVO, which the company said can help reduce carbon emissions by up to 90% without needing any modifications.

Further supporting the company’s strategy, Power Systems launched Conscious Care, a new maintenance program that includes multiple maintenance protocols to help customers lower greenhouse gas emissions and reduce their carbon footprint. In addition, it introduced a 100-kW Solid Polymer Electrolyte Membrane fuel cell system using green hydrogen for emergency backup, peak shaving, and demand response.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM