Optomec: Equipment Used To Refurbish 10 Million Turbine Blades

24 August 2020

Additive manufacturing technology provider Optomec said a recent survey of its customer installations using its 3D metal printers specifically for gas turbine component repair found that over 10 million turbine blades have been refurbished.

Optomec said it has metal additive repair machines installed at all leading gas turbine OEMs, in both the energy market for power generation and in aviation. Additionally, many of the third-party maintenance, repair and overhaul (MRO) shops also use Optomec systems, the company said. The solutions include Optomec’s Huffman brand five-axis laser cladders and its LENS brand metal additive 3D printers—both based on directed energy deposition (DED) technology that Optomec was first to bring to market.

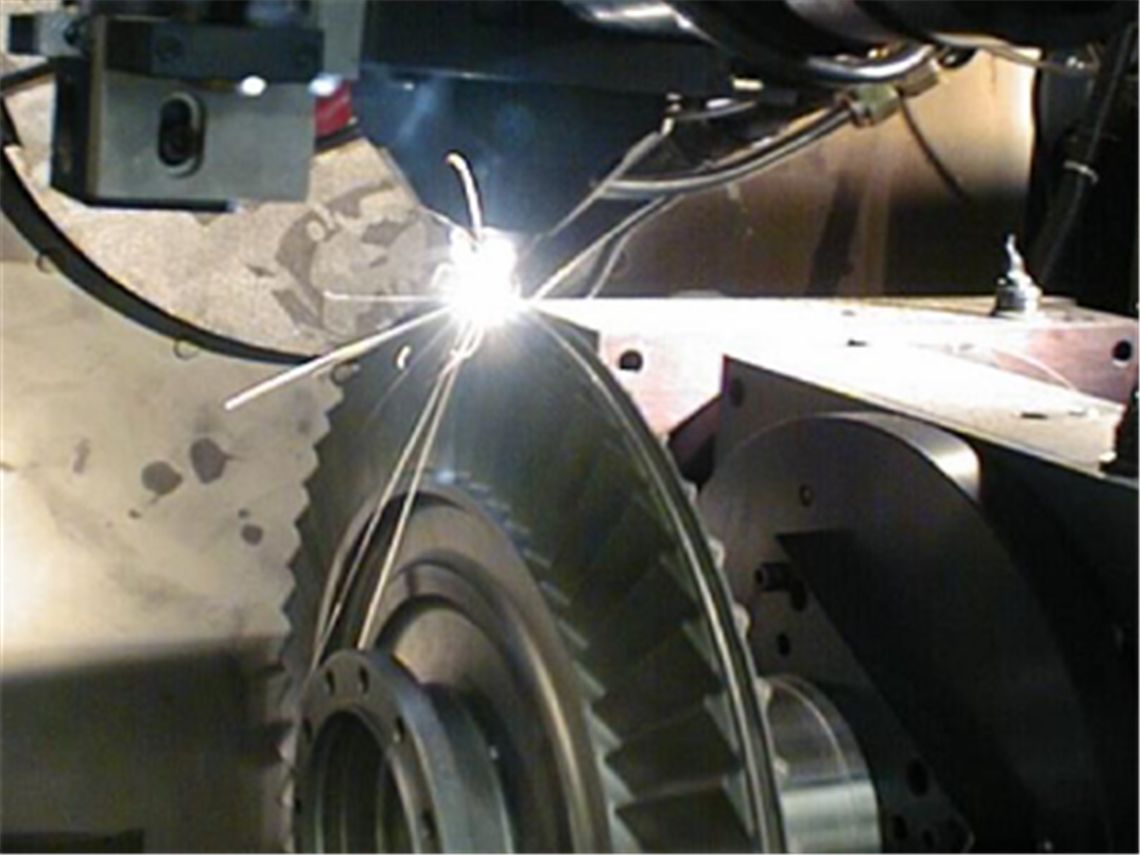

Common production applications include the repair of turbine blade tips, seals and wear surfaces; compressor blades, including titanium alloys; vanes, shrouds and other high-value components. Optomec’s automated solution typically replaces manual operations, such as tungsten inert gas (TIG) welding, and drastically reduces the cost of routine maintenance.

“We are really excited to reach this important milestone for both the Additive Manufacturing segment and, more important, for our gas turbine customers,” said Mike Dean, marketing director at Optomec.

Optomec said its customers benefit specifically from innovations in the following critical areas: 1) proprietary vision and adaptive control software, 2) controlled inert atmosphere processing for superior metallurgy, 3) turn-key repair process recipes, and 4) automation solutions that enable higher throughput batch processing.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM