Engineering smarter hydraulic systems

02 October 2025

Texas Hydraulics expands engineering service offering for OEM applications

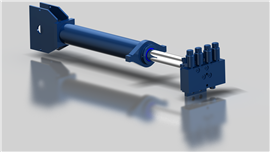

The Texas Hydraulics EAS-i cylinder is a self-contained hydraulic actuator with an onboard electronic controller, integrated manifold and sensors. (Photo: Texas Hydraulics)

The Texas Hydraulics EAS-i cylinder is a self-contained hydraulic actuator with an onboard electronic controller, integrated manifold and sensors. (Photo: Texas Hydraulics)

Today’s fleet operators and original equipment manufacturers (OEMs) in markets such as utilities, forestry, agriculture and construction are asking more from their hydraulic systems than ever before. Beyond raw power, they now want productivity, data-enabled diagnostics, rapid serviceability and responsible environmental performance.

Texas Hydraulics, based in Temple, Texas, said it can meet those challenges head on through its expanded system – level design and integration services – helping customers simplify complexity, accelerate development and unlock new levels of performance.

Based on decades of experience, the company now offers system-level support that can ease the burden on OEM engineering teams while shortening product development cycles. From integrating advanced technology into components to complete system solutions, Texas Hydraulics said it can help OEMs get to market faster with more confidence.

“Being first to market is critical,” said Josh Stevens, director of Engineering. “By partnering from day one, we ensure hydraulic systems not only meet technical requirements but also set benchmarks for reliability, ease of service, and performance.”

Smart cylinders

The company creates systems based on its catalog of components. At the forefront is the EAS-i cylinder, a self-contained hydraulic actuator with an onboard electronic controller, integrated manifold and advanced sensors. The EAS-i provides plug-and-play installation and delivers closed-loop control of complex machine motions through CANbus or J1939 integration.

Other benefits include:

■ Onboard programmable logic for machine function automation

■ Closed-loop feedback: pressure, temperature, cycles, position, velocity

■ Integrated manifold with load-holding, pressure, flow and proportional control

■ Real-time diagnostics for predictive and preventive maintenance

■ Customizable for different markets, e.g., utilities, forestry and construction

By consolidating sensors, valves and logic into the cylinder, the company said EAS-i reduces external plumbing, lowers contamination risk and simplifies assembly. Customers report significant reductions in downtime, improved safety in high-risk applications,and measurable efficiency gains from optimized hydraulic flow.

Modular system offerings

Texas Hydraulics can also deliver advanced solutions to address broader OEM challenges thanks to its Oilgear and Hydromotion businesses, such as:

■ Hydromotion fluid swivels and Power Plate slip rings: Leak-free, modular designs for combined hydraulic and electrical/data transfer, easing hose management and improving reliability.

■ Oilgear AM Series axial mount rotary actuators offer compact, high-torque rotary motion solutions, giving OEMs supply chain alternatives in agriculture and forestry.

■ Oilgear XD5 Series axial piston pumps engineered for extreme pressures and long life, with compact designs that save space and simplify OEM layouts.

OEMs can also streamline production by partnering with Texas Hydraulics on its modular, plug-and-play system assemblies, including pre-packaged kitted subsystems for rapid, consistent line installation. This approach can reduce sourcing complexity, improve consistency and speed installation on the production line.

With pressure on OEMs to design compact, durable and intelligent machines, Texas Hydraulics said it can deliver system-level expertise to bridge the gap. Whether validating a preferred supplier’s design, creating custom manifolds or integrating next-gen actuators, it provides solutions that maximize uptime, safety and efficiency.

The Oilgear Company was added to the Texas Hydraulics portfolio in 2018, giving its engineers and customers access to a broad range of hydraulic components.

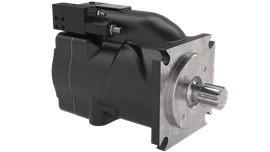

Recently, Oilgear expanded its line of XD5 axial piston pumps. Designed to serve customer needs in off-highway, energy and industrial hydraulics, the company said the XD5 series is engineered to deliver more power in a smaller, lighter package.

The XD5 model range covers displacements from 50cc to 150cc per revolution, with nominal operating flows from 22 to 42.4 gpm (83.3 to 160.5 l/min), and continuous pressures up to 5,000 psi (350 bar).

The XD5 series is up to 35% lighter than Oilgear’s previous pumps, which the company said will be ideal for OEMs seeking high power density in tighter spaces. (Photo: Texas Hydraulics)

The XD5 series is up to 35% lighter than Oilgear’s previous pumps, which the company said will be ideal for OEMs seeking high power density in tighter spaces. (Photo: Texas Hydraulics)

Other features include:

■ Advanced three-way, direct-acting control that delivers almost instantaneous response to system demands for greater operational efficiency in extreme environments.

■ The compact XD5 series is up to 35% lighter than the company’s previous pumps, which it said will be ideal for OEMs seeking high power density in tighter spaces and mobile platforms.

■ With proprietary Hard-on-Hard technology, Oilgear’s bearing and surface engineering dramatically improves service life and contamination resistance, even under continuous, heavy-duty cycles.

■ The model is built to handle standard hydraulic oils and low-lubricity fluids for expanded application versatility.

■ Available in side-ported and rear-ported configurations; compatible with SAE mounting faces for straightforward equipment integration.

■ Peak pressure ratings up to 5,800 psi (400 bar) for extreme hydraulic applications.

“With the launch of the complete XD5 series, Oilgear is strengthening its commitment to equipment reliability and lifecycle value,” said Jared Van Pelt, sales manager, Oilgear. “Engineered for rugged environments and backed by Oilgear’s global support network, XD5 pumps set a new benchmark for next-generation hydraulics.”

The hydraulic rotary actuator Axial Mount (AM) Series is Oilgear’s latest product family. Built for high performance, reliability and adaptability, the actuators are designed for OEMs in sectors such as construction, agriculture, mining and energy.

“The AM Series stands apart for its high axial loading capacity and compact space claim that also can be a drop-in installation for both new and existing equipment,” said James Warner, product manager, Oilgear. “With helical gear engineering, these actuators deliver high drive and holding torque in minimal space, offering OEMs more design flexibility without sacrificing costly and weight contributing workarounds.”

Features include:

■ Engineered for robust performance in heavy-duty pivot and hinge control, supporting demanding loads across multiple industries.

■ Takes up less space than other hydraulic actuator series without sacrificing power, making integration easier in tight equipment footprints.

■ Integrated counterbalance valves ensure secure stopping and continuous holding, even under external forces, for leak and drift-free operation.

■ Composite bearings handle overhung loads and ensure quiet, reliable torque delivery across every cycle.

With the AM Series, Oilgear offers radial capacities from 3,000 to 8,000 lb and moment capacities up to 50,000 in.-lb, with 180° standard rotation and 360° options available.

The AM Series is suited for precision pivot control in heavy-duty equipment. The modular product architecture accommodates customer-specific mounting, rotation limits and specialized fluid requirements, making it suitable for applications across construction, utilities, marine, military and more.

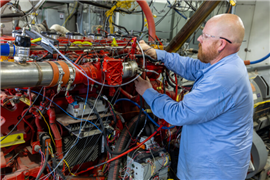

Texas Hydraulics hosted AEM’s Manufacturing Express tour at its Temple, Texas, location. (Photo: Texas Hydraulics)

Texas Hydraulics hosted AEM’s Manufacturing Express tour at its Temple, Texas, location. (Photo: Texas Hydraulics)

AEM Manufacturing Express visits Texas Hydraulics

Texas Hydraulics welcomed the Association of Equipment Manufacturers’ (AEM) Manufacturing Express as part of the association’s monthlong Texas tour in August.

The event was highlighted by a presentation from Temple, Texas Mayor Tim Davis, who issued an official proclamation recognizing Texas Hydraulics for its commitment to manufacturing and its contributions to the Temple community.

The AEM Manufacturing Express brought together local leaders and employees to celebrate the role of manufacturing in Texas. The event recognized the dedication of the Texas Hydraulics team, engaged the community, and spotlighted the impact of a variety of manufacturers across the state.

“Opening our doors for this event was an incredible opportunity to showcase our talented team and the work they do every day to support our employees, community, and industry,” said Naimesh Dave, CEO, Texas Hydraulics Holdings. “Receiving Mayor Davis’s proclamation was a meaningful honor that reaffirms our commitment to Temple and the strength of local manufacturing.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM