Read this article in 中文 Français Deutsch Italiano Português Español

Solid oxide fuel cells provide backup power for small-scale, hybrid applications

03 December 2024

The Watt Remote SOFC is designed to be integrated with an energy storage/solar power solution. (Photo: Watt Fuel Cell)

The Watt Remote SOFC is designed to be integrated with an energy storage/solar power solution. (Photo: Watt Fuel Cell)

Backup power addresses a continuum of applications, from residential to industrial. Regarding the latter, generator sets and battery energy storage systems (BESS) are currently in competition. Many BESS manufacturers have been able to scale their systems to provide the multi-megawatts of power that could previously only be supplied by large industrial gen-sets.

Gen-sets are similarly used in a backup power niche that could best be described as commercial. These applications typically require a reliable emergency power supply but do not call for the amount of power necessary in industrial situations.

Competing with gen-sets in smaller commercial applications are solid oxide fuel cells (SOFC).

Danielle Ramaley, vice president of sales and marketing for SOFC maker Watt Fuel Cell, which is based in Mount Pleasant, Pa., said the easiest way to describe an SOFC is to think about a battery.

“It’s the same kind of electrochemical device, where you have an anode, a cathode [and] an electrolyte. But rather than just storing energy, an SOFC can create energy as long as you have a fuel source.”

She said that an SOFC chemically converts fuel — primarily natural gas — into DC electricity.

“It’s all catalytic — no combustion,” Ramaley said, adding that benefits include very low noise “because you don’t have the rotating equipment of a traditional combustion-based process” and significantly reduced emissions.

“No NOx (nitrogen oxides), no SOx (sulfur oxides), no particulate,” she said.

Gaseous Fuel Sources

While Watt’s SOFCs primarily use natural gas, Ramaley said they can also use propane.

“In some of our projects, we can do blended hydrogen in either of those fuels, up to about 20 percent blended hydrogen, as well,” Ramaley said. “But the focus for Watt has been on readily available, commercially available fuels that are easy to procure.”

She added that many remote applications are propane-based, as are RV applications. When used in residential applications, the fuel of choice tends to be natural gas, Ramaley said.

Small-Scale Applications

“I would say from a marketplace perspective, Watt is focused on small-scale power, and we really apply to three different markets,” Ramaley said.

Two of those are residential power, which can either be primary or backup power, and recreational applications, such as in recreational vehicles (RV). The third market is remote power applications, in which Watt’s SOFCs typically work in concert with other energy generation and storage technology, including batteries, Ramaley said.

The Watt Nomad SOFC is designed for the RV market, which is one of Watt Fuel Cell’s key markets. (Photo: Watt Fuel Cell)

The Watt Nomad SOFC is designed for the RV market, which is one of Watt Fuel Cell’s key markets. (Photo: Watt Fuel Cell)

“We really form a great energy system that is very applicable to those types of applications that are, you know, ‘I’m in the middle of nowhere and I need power that’s going to be reliable, resilient and clean,’” she said. “When you pair solar together with a battery and a [solid oxide] fuel cell, when you don’t have that solar operating, you have the fuel cell always there, able to cycle and run as you need it.”

Ramaley said other applications include securing remote equipment, such as oil and gas wellheads, as well as some more unique uses of the technology.

“When I think about some of the industrial [and] commercial applications we’re focusing on with our reseller partners, they are things like remote security and surveillance,” she said. “We have one customer who is focused on things like facial recognition software. They have a contract for Amber Alerts — missing people.”

Unique Technology

Ramaley said that Watt’s SOFC technology is unique compared to competitive technologies, which she described as “planar” SOFCs.

“About the size of a coaster is what the fuel cells look like, or a Post-It note,” she said of planar SOFCs. “Those fuel cells are stacked up in a in a series of stacks, like a deck of cards. Our fuel cells are microtubular, so they are about the size of a pen. They are arranged in a stack of cells together.”

According to Ramaley, that tubular geometry and configuration makes Watts SOFCs particularly well suited to thermal cycling and load following as well as being able to turn on and off several times.

“Traditionally, planar SOFC technology does not like to be cycled on and off,” she said. “It likes to be on and operating at a consistent power output. But microtubular fuel cells do really well with cycling, and our technology is built around that cycling. So, leaning into the commercial and industrial applications or remote power applications, we are an excellent technology for that cycling need.”

A Small Footprint

Unlike traditional gen-sets, even many portable ones, Watt’s SOFCs can literally fit on a countertop.

“Our unit is about the size of a home microwave that you’d put on the counter,” Ramaley said. “It’s relatively small in size — about a little over 2 ft., and then 2 ft. wide, and then about a little over 1 ft. each way.”

She added that the footprint remains the same regardless of power output. “We have about a 500 Watt system and a 1.5 kW system.”

Ramaley said the average power output for residential use in the U.S. is about 1.2 kW, which can consistently meet that average base load of a home when paired with energy storage.

“You’re able to then cover your peaks and have clean backup power whenever you need it, essentially,” she said.

Reduced Fuel Consumption, Maintenance

Ramaley said that SOFCs used as a backup to a solar system that otherwise would rely upon a traditional gen-set for backup power can offer fuel savings of 60 to 90 percent.

“In some cases, the fuel cell can sit for days and days,” she said. “In some cases, it might be cycling daily, [as] during wintertime. So, having a [power] source that is able to reduce your fuel consumption that 60 to 90 percent over combustion-based products really enables those remote locations to experience less field service maintenance.”

Further reducing maintenance, in addition to a lack of moving parts, is the ability to monitor the SOFC via any internet connection.

“So, when these are truly remote applications that you have to send a field service crew out into a middle-of-nowhere scenario, you’re able to monitor the fuel cell operation remotely as long as you have internet access and see what’s happening in real-time with your energy storage levels, your battery levels, state of charge, how much solar you’re producing, as well as is the fuel cell cycling.”

Modular and Scalable

For larger applications or ones that might occasionally require more power than a single unit can provide, Ramaley said the fuel cells are modular and scalable.

“We use CAN communication to tie our units together,” she said. “We can tie about 10 units together, and they can intelligently communicate among them. So, if you don’t need a large level of power draw for a period of time, they will intelligently cycle between the units and cycle the first unit, then the second and the third. But if you would need multiple units cycling at once, they are capable of doing that, as well.”

Watt applies 3-D printing technology to produce SOFCs

Watt Fuel Cell prides itself on using 3-D manufacturing in producing its solid oxide fuel cells (SOFC).

“That is Watt’s claim to fame,” said Danielle Ramaley, vice president of sales and marketing for Watt Fuel Cell, “and a large part of our proprietary technology is based around the way we manufacture our tubular fuel cells.”

An automated robot used in Watt’s 3-D printing process. (Photo: Watt Fuel Cell)

An automated robot used in Watt’s 3-D printing process. (Photo: Watt Fuel Cell)

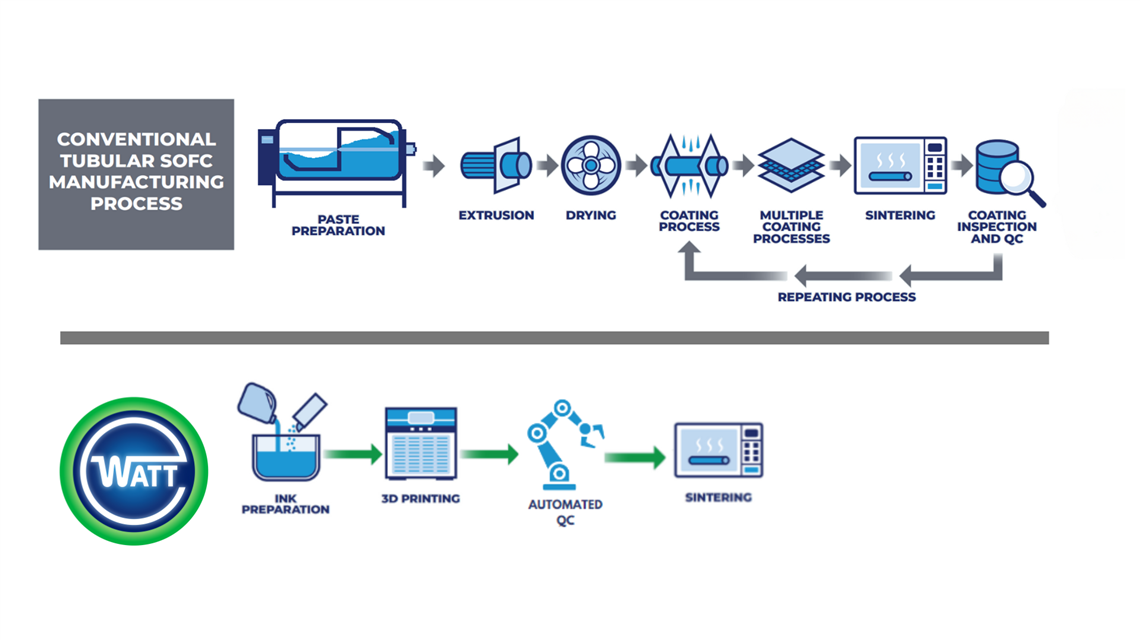

Ramaley said tubular fuel cells like those Watt makes are produced via an extrusion process.

“It’s just like making a piece of rigatoni,” she said, referring to the type of pasta. “You are making a paste. You’re extruding that out, and then you’re going through multiple processes of layering on that and layering on that electrolyte and the cathode. It’s a very iterative and long process.”

With this extrusion process, it takes about 200 hours to make a tubular fuel cell, Ramaley said.

“Watt has focused the development of the technology around being economical and viable at scale,” she said. “So, we focused from the beginning on 3-D printing. And now we’ve taken a process that takes about 200 hours traditionally and taken it down to four minutes.”

In addition to the significant reduction in manufacturing time, Ramaley said another benefit of Watt’s 3-D printing technology is the level of detail it provides.

“We are actually printing down at the micron level, so about half the size of a human hair is the level that we’re printing at,” she said. “This enables us to control not only the quality of our fuel cells but also the way in which they are printed and constructed.”

Ramaley said this allows Watt to design its SOFCs to maximize efficiency due to the fine level of detail — something not possible with extrusion.

Watt’s manufacturing process vs. the traditional extrusion process. (Image: Watt Fuel Cell)

Watt’s manufacturing process vs. the traditional extrusion process. (Image: Watt Fuel Cell)

“We’re headquartered in Mount Pleasant, Pa., just outside of Pittsburgh, and we just went through a large expansion,” Ramaley said. “The focus of that expansion was to expand our 3-D printing capabilities. We now have the capacity to produce between 1500 and 2000 units a year.”

Watt can use its 3-D printing capability to manufacture SOFCs around the clock.

“We use multiple printer processes with a robotic arm and robotic computer-based QC (quality control) visual inspection,” Ramaley said. “We’re able to take the human element to some extent out of that production process, which gives us a high level of quality and repeatability to produce really high-quality tubular fuel cells.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM