ExxonMobil, GE Launch Gas Turbine Oil

20 November 2019

ExxonMobil and GE announced the launch of Mobil SHC 918 EE gas turbine oil, a new technology that can improve turbine bearing efficiency by up to 15% compared to conventional ISO VG 32 turbine oils.

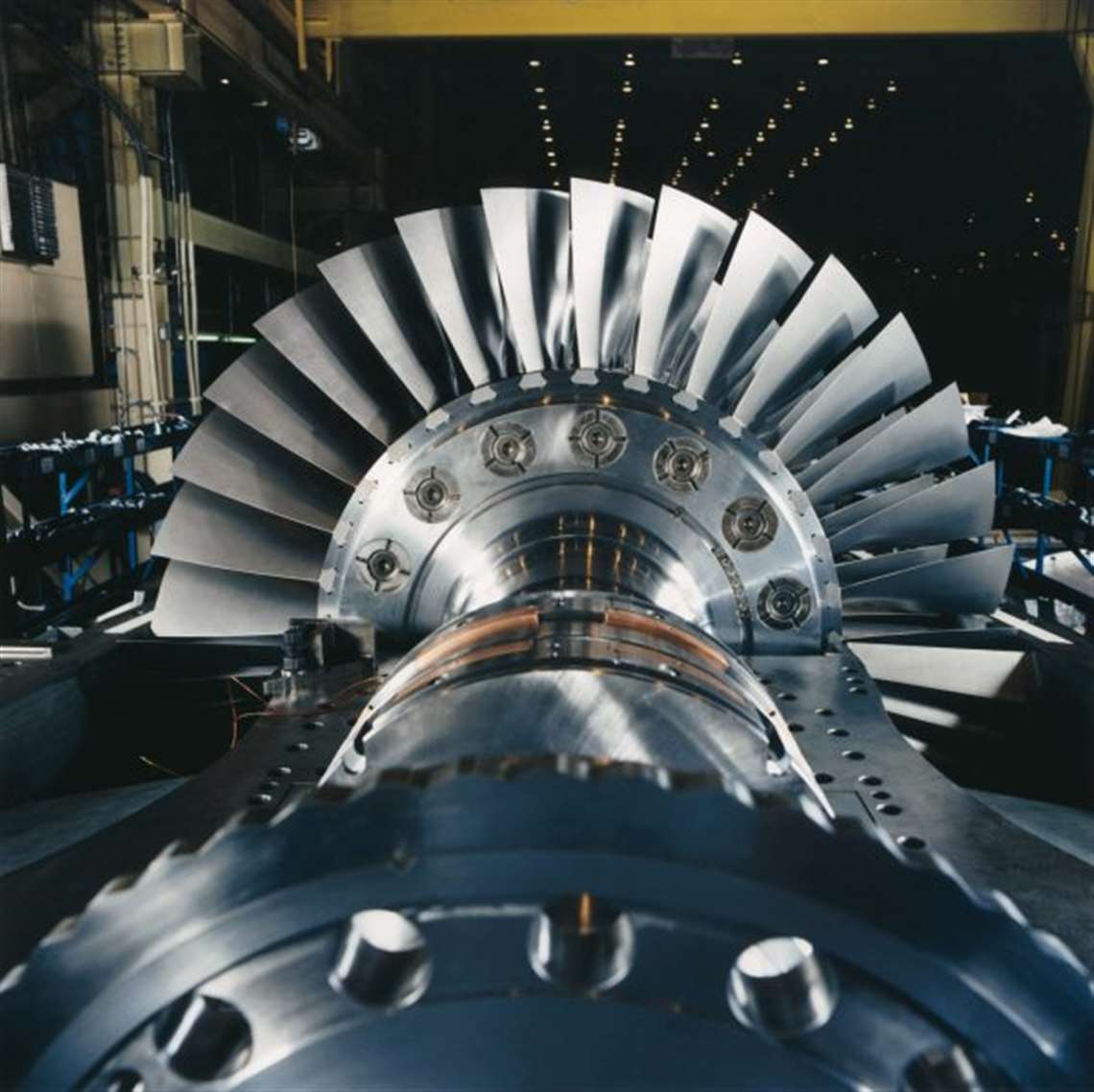

Designed for use in multi-shaft 7HA, 9HA, 6FA.01 and 7FA GE gas turbines, the turbine oil is designed to help power plant operators reduce production costs and deliver on sustainability goals through lowered carbon dioxide emissions.

Improving turbine energy efficiency is a significant focus for the power generation industry. Improving efficiency can help reduce fuel costs, which can account for up to 80% of total running costs, and extend component life by reducing operating temperatures. These improvements can lead to lower capital expenditures and maintenance costs.

Developed in collaboration with GE, this gas turbine oil is the first lubricant to meet GE’s Energy Efficient (EE) GEK 121603 turbine oil specification, which GE developed exclusively for its high-performance turbines.

“More efficient gas turbines are critical to the success of the power generation industry, and we’re committed to leading the charge by delivering innovative technologies that help operators minimize cost to produce while maintaining high reliability and improving sustainability,” said John Lammas, vice president of Engineering for GE Power. “Many operators may not think about the importance of gas turbine oil, but this new technology developed in partnership with ExxonMobil delivers step-out performance that can singlehandedly deliver an impactful efficiency improvement.”

GE and ExxonMobil collaborated to develop Mobil SHC 918 EE gas turbine oil through a process that involved three phases:

- GE developed a test rig to simulate turbine bearing surface speeds under varying load conditions to select the optimum turbine oil to provide energy efficiency benefits.

- Mobil SHC 918 EE was then successfully tested in GE’s Test Stand both 7HA and 9HA gas turbines. Performance was monitored by 4000 sensors through a battery of extreme testing conditions, including critical speed startups under a variety of operating conditions.

- GE then field-tested Mobil SHC 918 EE in 6FA & 7FA turbines, running reliably for over two years.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM