Bearing seal from SKF, Great Plains collaboration reduces downtime

19 May 2021

SKF and its Peer brand engineered new seal to withstand harsh agricultural conditions.

SKF, a supplier of bearings, seals, lubricants, and condition monitoring systems, said it worked in partnership with Great Plains Mfg., a manufacturer of pull-type agricultural implements, to create a new seven-lip seal package to prolong the life of agricultural tillage equipment.

Introduced last year, the Great Plains Terra-Max is designed for producers looking for a versatile tillage solution to address a wide variety of fall and spring field conditions. The company calls it a hybrid tillage solution as it uses a blend of vertical and conventional tillage methods to allow for an aggressive field pass at higher operating speeds.

Introduced last year, the Great Plains Terra-Max is designed for producers looking for a versatile tillage solution to address a wide variety of fall and spring field conditions. The company calls it a hybrid tillage solution as it uses a blend of vertical and conventional tillage methods to allow for an aggressive field pass at higher operating speeds.

Great Plains Ag, a division of Great Plains Mfg., develops tillage equipment for seedbed preparation. In the Black Earth Region of Russia, key bearings critical to the operation of tilling equipment were wearing out halfway through the growing season. During analysis by SKF and Great Plains engineering teams, significant dirt pack intrusion was found to be a common issue impacting the function of the bearings and leading to machine downtime.

In response, Great Plains and SKF engineers worked to update the machinery’s design to include a more robust bearing seal that would help better prevent dirt pack-related failures. SKF in the U.S. developed a seven-lip seal by redesigning the seal package to help eliminate dirt pack between the bearing, housing and spool, which outperformed the existing seal design. By minimizing the pressure from the dirt pack against the seals, said SKF, the equipment can operate more effectively for a longer life cycle.

“Our long partnership with Great Plains led to this successful collaboration to develop an agricultural bearing that can withstand some of the most extreme climate challenges found around the globe. It’s a great development for the agricultural community, as it creates a more durable, longer lasting bearing, which extends the availability of the equipment, and increases uptime in the field,” said Chris Larson, strategic account manager for SKF USA, Lansdale, Pa.

In addition to retrofitting older tilling machinery models with the newly redesigned seven-lip TILLXTREME seal, Great Plains also included the TILLXTREME seal on its new Great Plains hybrid tillage solution, the Terra-Max, when it launched in September of 2020. Initial in-field testing has been positive, said SKF, earning high marks from the farmer and outperforming all the customer’s goals for uptime and availability.

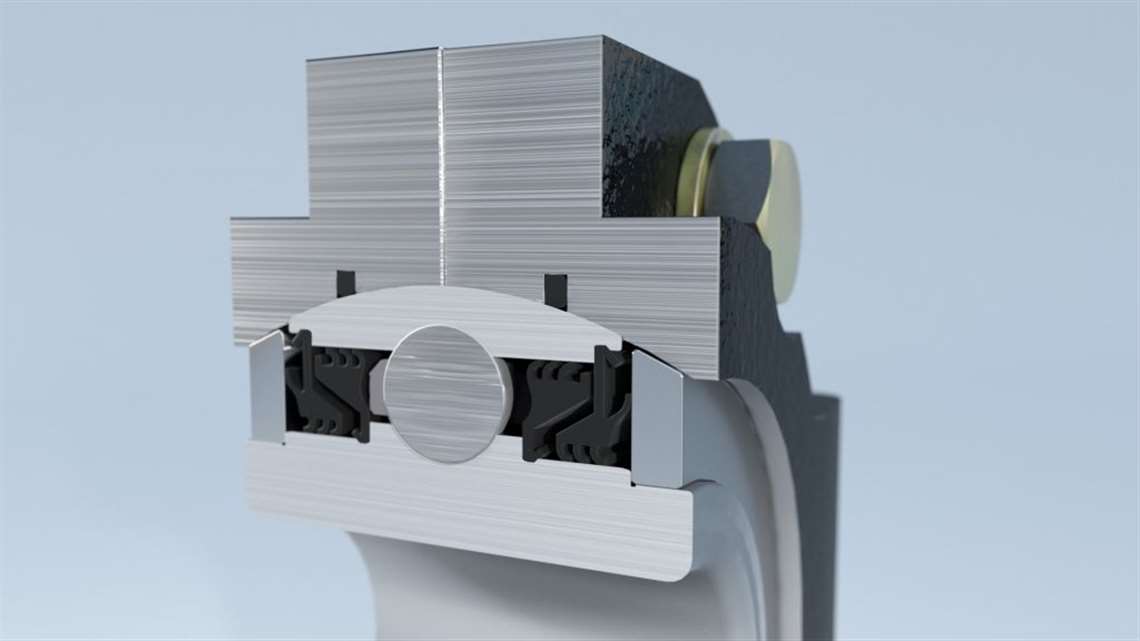

A cutaway of the TillXtreme bearing seal developed by SKF brand Peer in partnership with Great Plains.

A cutaway of the TillXtreme bearing seal developed by SKF brand Peer in partnership with Great Plains.

“Working with our long-time partner SKF Group on this specific challenge, led to a collaborative solution that enabled a better, longer-lasting product for all our customers globally.” said Rodney Hake, engineering manager for Great Plains, Salina, Kan. “Our new Terra-Max tillage line-up leaves a uniform, unrestricted soil profile that promotes maximum root development and increases yields for farmers working in the world’s most challenging areas.

A Kubota company, Great Plains manufacturers grain drills as well as tillage equipment, fertilizer applicators, sprayers and planters.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM