Harvesting electrification in the agricultural sector

29 July 2021

Roberta Prandi learns from lithium battery specialist Flash Battery why some types of agricultural machinery are among the most dynamic towards adopting electrified solutions.

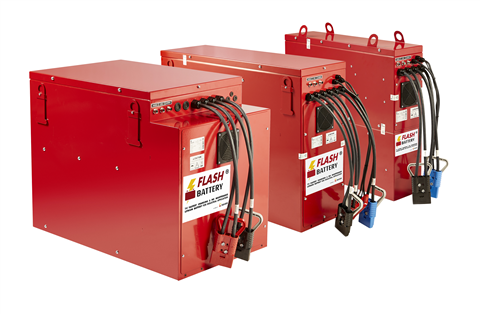

According to Flash Battery, an Italian-based specialist in lithium batteries for industrial vehicles, the agricultural sector is one of the emerging markets for electrification throughout Europe.

This sector is undergoing major technological changes. Concerns over environmental problems appear to be a main driver to turn to electric power, along with public policies and very strict regulations on the emission of pollutants.

The agricultural sector is one of the markets that is undergoing major trends towards electrification in Europe, according to Flash Battery

The agricultural sector is one of the markets that is undergoing major trends towards electrification in Europe, according to Flash Battery

Flash Battery is the most sold lithium battery in Italy, which recharges the fastest and requires no maintenance, thanks to its proprietary remote control system.

The company commented that the electrification of European agriculture has begun in multiple applications. This is a process that offers major opportunities such as environment protection, reduced maintenance operations and management costs.

Marco Righi, who leads a young and energetic team, said, “The agricultural machinery industry is investing huge amounts of resources into electrification”

Marco Righi, who leads a young and energetic team, said, “The agricultural machinery industry is investing huge amounts of resources into electrification”

Marco Righi, CEO and founder of Flash Battery, explained: “The agricultural machinery industry is investing huge amounts of resources into electrification.

“Just think of the evolution in terms of the skills that research and development teams need to deal with.

“First they were used to internal combustion engines and hydraulic equipment. Now they need to work with batteries, inverters, electric motors and CAN-bus systems among others.”

European trend towards electrification

The trend towards electrification across Europe has been registered through data by the company’s French partner EFA France, which emphasises the industrial electrification in agriculture – with considerable interest in self-driving vehicles and machinery for medium-intensity use.

Flash Battery noticed a significant increase in demand from numerous European players in France and the Netherlands during the first six months in 2020.

The company anticipated several fields of application in which the need for electrification of agricultural vehicles is becoming more pressing. One of them is straddle tractors used in vineyards for soil tilling, cutting, clipping, phytosanitary treatment etc.

Viticulture is an important agricultural sector that has been enjoying strong growth with an ongoing strive for improved quality, simplified work processes and greater precision. These are the determining factors for a trend towards electrified machines.

Thanks to electric power, straddle tractors achieve the same levels of performance as internal combustion-powered tractors. Yet at the same time they gain all the advantages of electric drives. Namely the elimination of maintenance with related costs, cutting CO2 emissions, diminishing harmful gas and fine particulate emissions as well as reducing noise.

Another niche that sees electrification as a necessary step forward is the maintenance of urban green spaces. Obvious advantages include using these machines at any time of day, reducing noise pollution and the resulting disturbance on people’s daily lives. The use of lithium-ion batteries also makes these machines lightweight, practical, compact and easy to use.

Flash Battery use LFP chemistry, the safest and most stable on the market, for industrial applications

Flash Battery use LFP chemistry, the safest and most stable on the market, for industrial applications

Why lithium batteries are a game-changer

According to Flash Battery, another factor influencing the demand for electrification in the agricultural market is the need to reduce energy consumption in a sector that is by nature very energy hungry.

Giulia Gibertini, head of communication and marketing at Flash Battery, defined lithium batteries as the game-changer because of their capacity to overcome the limit to store energy of previous lead acid-based solutions.

The fact that nowadays lithium batteries reach compliance – in terms of shape, size and technical specifications – has also been a major step forward.

Gibertini said, “Greater energy density in a smaller space is one of our key strengths, along with the high safety levels that we guarantee in all 10,000 of Flash Battery’s products already in use around the world.”

Flash Battery rely on lithium iron phosphate (LFP) chemistry for industrial applications, because it is the safest and most stable chemistry on the market. It is also available in high capacity formats that do not require to connect many cells in parallel, further increasing safety and stability.

To improve the power capacity and life of its batteries for industrial uses, Flash Battery researched and adopted solutions that increase energy density inside the LFP packs.

The company’s R&D team, which accounts for just over a third of their workforce, was able to increase volumetric power density from 134 Wh/L to 207 Wh/L in just three years.

Flash Battery analyses each individual project starting from the requirements in terms of power, autonomy and the space available for the lithium battery. The company manages cooperation with the client, from the design phase through to delivery.

Righi explained that although initially lithium-battery technology raised doubts, creating a negative image and some hesitance in adopting the new solutions, it is important to trust an experienced lithium battery manufacturer.

He concluded, “Flash Battery has always managed to guarantee the highest safety level by working on three key aspects. Namely, choosing the right lithium chemistry, a proprietary control electronics and the correct assembly of the battery pack.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM