Expanding In The Cloud

06 November 2017

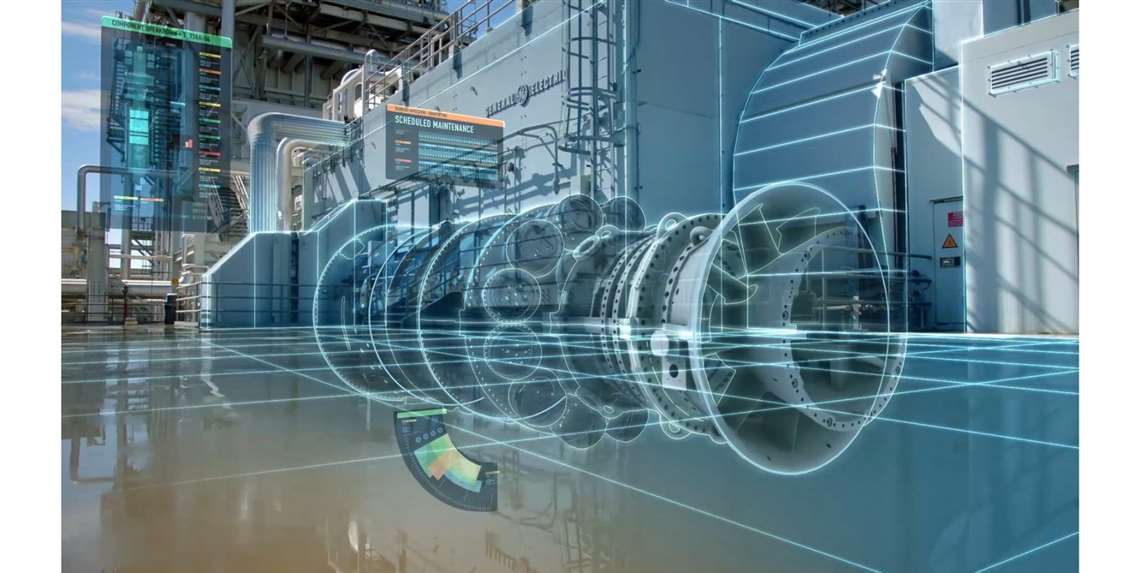

GE unveiled expansions to its suite of edge-to-cloud technologies and industrial applications, designed to help its customers build a complete asset strategy.

These additions to the GE Digital portfolio are designed to complement the software applications that drive industrial productivity and extend these benefits through Predix, the application platform developed by GE.

The Predix system, which was introduced in 2016, is being widely accepted across markets, said GE CEO John Flannery, during at GE’s Minds+Machines event held in San Francisco, California, USA.

In the energy market segment, GE received $5 billion in Predix orders in 2017—a 100% increase from the previous year, Flannery said.

“Predix underpins a suite of applications, from asset performance management to field service transformation and beyond,” Flannery said. “And they allow us to go from data to insight into action to outcome—our customers are getting real results.”

At the event, GE Digital introduced Predix Edge technologies designed to accelerate computing at the edge; the Predix platform combined with Microsoft Azure, the cloud for enterprises; new Operations Performance Management software designed to bridge productivity from assets to operations; enhanced Field Service Management solutions aimed at improving customer experience; and new platform tools designed to simplify industrial app development.

“Industrials that unlock data to master asset productivity will be positioned to lead,” said Bill Ruh, chief digital officer of GE and CEO of GE Digital. “To power digital transformation, industrial organizations must understand every stage of the asset lifecycle. The company that designs, builds, operates, maintains and services industrial assets is best equipped to help others with their Industrial IoT journeys. And only GE offers the combination of industrial apps, underpinned by an industrial platform, to ultimately drive customer outcomes.”

To help customers accelerate their edge strategies and make any asset, such as a turbine, an intelligent asset, GE Digital said it is expanding its Predix Edge capabilities to help run analytics as close to the source of data as possible. Predix Edge is designed to give customers with limited connectivity, latency limitations, regulatory or other constraints a way to deploy applications closer to the originating data – or at the edge. Enhancements include:

- Predix Edge Manager allows customers to support large fleets of edge devices – up to 200 000 connected devices from a single console.

- Predix Machine enables microservice-based applications to run at the edge on customers’ virtualized data center infrastructure or on server-class hardware from GE or its partners. This also supports Predix Edge Manager, which was previously available only as a cloud service.

- Predix complex event processing(CEP) allows for faster and more efficient analytics and other event processing at extremely low latency, available at the edge in Q1 2018.

These edge solutions can help companies move from intelligent asset management to automation to insights-led machine learning across a distributed system, GE said. One example is EdgeLINC, a comprehensive edge-to-cloud solution from GE Transportation integrated with Predix Edge Manager, Predix Machine, and Asset Performance Management applications. EdgeLINC enables efficient device management, configuration and streaming analytics even when machines, such as rail assets, are constantly moving in and out of communication.

GE Digital also said that it and Microsoft are bringing together the advanced industrial platform services of Predix with the services of Microsoft Azure. Available in North America starting in the fourth quarter 2017 and expanding globally in 2018, this partnership extends the accessibility of Predix to Microsoft’s global cloud footprint, including data sovereignty, hybrid capabilities and advanced developer and data services, enabling customers around the world to capture intelligence from their industrial assets.

The partnership should help businesses better connect their information technology (IT) systems with their operational technology (OT) by bringing a company’s systems – and data – together in a shared environment. While IT and OT have traditionally existed in silos, Microsoft and GE are bridging this gap and giving industrial customers a way to more easily improve performance, increase operational efficiency and accelerate the shift from automation to intelligence.

Understanding how an asset operates and its maintenance needs is critical to mitigating risk and improving productivity, GE said. Alongside its Asset Performance Management (APM) software, the core application deriving value from industrial assets, GE Digital introduced a complementary application that improves the operational performance of assets – like pumps, valves, and heat exchangers – and drives a comprehensive asset management strategy.

This new Operations Performance Management (OPM) solution helps industrials increase revenue and margins, optimize the throughput of industrial processes and make their sites more profitable. OPM uses real-time and historical data and advanced analytics to help customers make better operational decisions. The solution provides an early warning if industrial processes deviate from plan, arms operators with the information and time to troubleshoot operational issues and helps them take preventative actions to meet business goals.

GE Digital’s OPM software initially targets the mining industry and will expand to additional industries early next year.

With service technicians looking to embrace technology to improve their productivity and deliver a better experience for customers, ServiceMax from GE Digital, the leading field service management (FSM) solution, announced several enhancements to its FSM suite – enabling even greater efficiencies and bringing advanced analytics to service operations.

Artificial intelligence-enabled predictive service times now integrate the Apache Spark AI engine to improve service time estimates. Additionally, a new application integration solution enables service providers to launch and share FSM data with third-party mobile applications installed on the same device.

New capabilities in schedule optimization allow for dependent job scheduling between work orders for multiple visits aimed at improving first-time fix rates. As part of GE Digital’s FSM portfolio, these new features allow operators to minimize downtime, optimize costs, reduce risk, and improve productivity for service teams.

GE Digital also introduced Predix Studio to help companies build and scale their own industrial applications and extend its Asset Performance Management (APM) suite, Available in the first quarter 2018, Predix Studio simplifies the development process by giving customers the ability to extend applications and empower industrial subject matters experts – or citizen developers – to build apps in a low-code, high-productivity environment.

To help customers capitalize on new growth opportunities, GE created the Digital Twin Analytics Workbench, a solution that applies a library of algorithms and templates to make it faster and easier for companies to build their own digital twins on Predix. GE’s experience in managing industrial assets has generated hundreds of millions of hours of machine data and a deep understanding of how machines perform in various conditions. Modeling that physical data into digital twin models allows GE to deliver applications that better predict and improve the performance of physical machines.

The Analytics Workbench, currently a technology preview from GE Power, can be used to augment existing digital twins with new data streams. For example, power producers using drones to inspect wind turbine blades, pipelines or fuel reserves can integrate visual inspection data into the digital twins they already use to manage generation assets and grid infrastructure. The Analytics Workbench also helps users implement machine learning capabilities that allow those models to improve themselves over time.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM