GE Oil & Gas Adds Gas Turbines

30 January 2017

GE Oil & Gas introduced what it calls super-efficient gas turbines, the LM9000 and NovaLT12, at its annual meeting in Florence, Italy.

“The best companies use volatile times as a catalyst to drive beneficial change,” said Rod Christie, president and CEO of Turbomachinery Solutions, GE Oil & Gas. “We have taken this industry cycle to reflect on what our customers will need in the future and are disrupting traditional product development to introduce smarter and more cost-effective advanced gas turbines that address the industry’s greatest needs; reliability, flexibility, efficiency and productivity.”

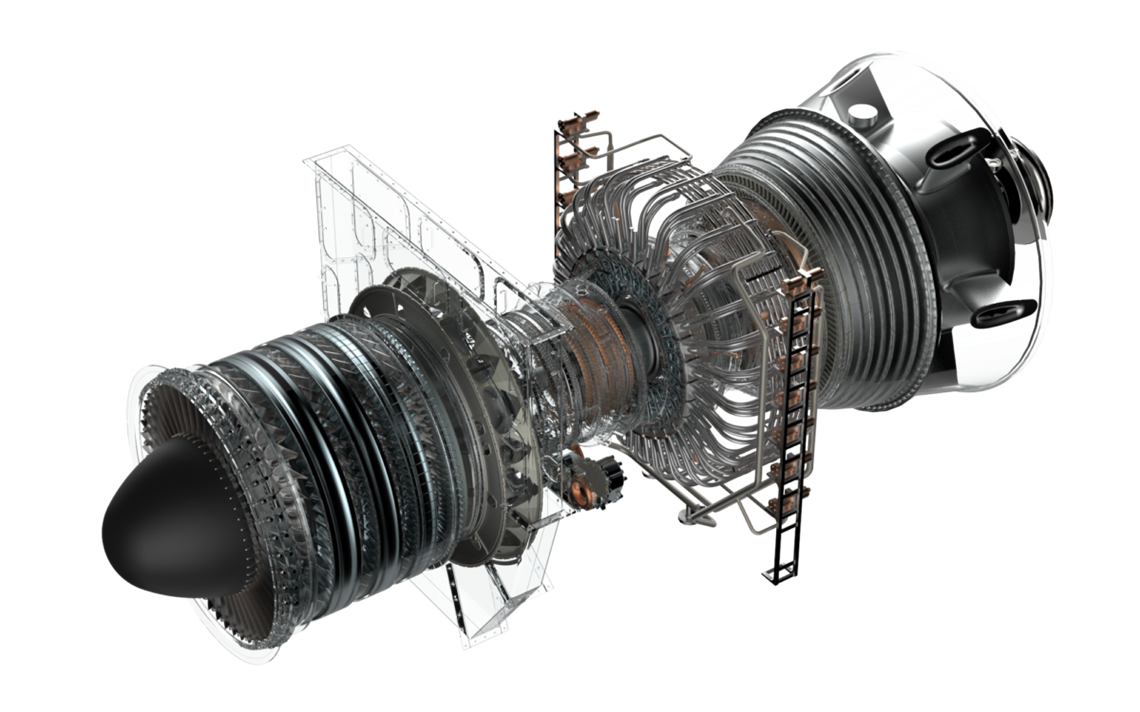

The LM9000 is a 65 MW, 43% simple-cycle efficiency aeroderivative gas turbine, derived from the GE90 jet engine fitted on Boeing 777. GE said a key design feature of the LM9000 is its free power turbine—enabling high efficiency power and speeds over a wide range of ambient conditions. It has a nominal speed of 3429 rpm and a 70% to 105% speed range.

Designed for mechanical drive, the LM9000 is also well suited for simple-cycle (peaking, mid-merit, base load), cogeneration, and combined-cycle power generation, the company said. With 43% simple-cycle efficiency, and over 80% efficiency in cogeneration configuration, this turbine can deliver a precise, dependable, safe, and flexible energy supply, the company said. In addition to liquefied natural gas (LNG) applications in off and onshore, it can also be utilized for simple cycle, cogeneration and combined cycle power generation, the company said. The LM9000’s modular package design enables shorter manufacturing cycles and faster installation, with lower installed and operational costs than field-erected units. Its compact footprint helps meet stringent space requirements, especially for retrofits or smaller, new plants. The driver package is 12.5 x 5 x 4.5 m.

Longer maintenance intervals and 24-hour engine swap capability (thanks to a mini skid for easy lateral removal of either the whole gas turbine or just the supercore) contribute to more than 99% availability, which is critical to LNG applications, the company said.

The NovaLT12 is the latest addition to GE Oil & Gas’s family of heavy-duty gas turbines. The NovaLT12 was developed with a special focus on oil and gas midstream operations — both mechanical drive and power generation — and is well suited to a wide range of upstream and downstream applications, the company said.

The NovaLT12 has a power output of 12.6 MW and included design options for power needs from 10.5 to 13.9 MW. It achieves a 36.5% efficiency at full load (32% at 70% load) and has a shaft speed of 8900 rpm.

The NovaLT12 leverages the success of the NovaLT gas turbines program overall, which includes the NovaLT16 and that of the NovaLT5, designed to meet residential, industrial and commercial customers’ needs with a reliable and efficient plug and play solution below 20 MW, the company said.

With an efficiency of up to 85% in cogeneration applications, these gas turbines represent an advanced solution to produce heat and power, and they can increase industrial plant efficiency while reducing NOx and CO2 emissions.

Standardization and modularization significantly reduce customized engineering needs, which means faster delivery time (36-week EXW, eight-week installation), the company said. The turbine’s end burners are manufactured using 3D printing technology at GE Oil & Gas’ additive manufacturing facility in Talamona, Italy. After extensive validation of additive during prototyping of the NovaLT16 gas turbine, GE decided to move the technology into full production, leveraging the design enhancement capabilities, cycle time reduction and improved product quality. GE Oil & Gas said the investment in these technologies reflects the ongoing commitment to combine cutting edge technology and new manufacturing processes to lower cost and accelerate the innovation, speed and performance of industrial products.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM