Going back 90 years: Diesel Progress July 1940

18 August 2025

Diesels spin silk

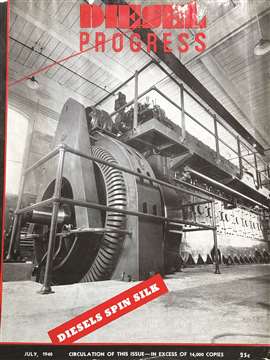

A Rathbun-Jones diesel engine rated 1,025 hp and made in Toledo, Ohio, shown here on the cover of the July 1940 issue of Diesel Progress, was installed in the New England Spun Silk Corp. factory in Brighton, Mass. The silk specialist closed its doors in 1962.

A Rathbun-Jones diesel engine rated 1,025 hp and made in Toledo, Ohio, shown here on the cover of the July 1940 issue of Diesel Progress, was installed in the New England Spun Silk Corp. factory in Brighton, Mass. The silk specialist closed its doors in 1962.

Starting with the May 1935 issue, Diesel Progress – or Power Progress as it’s known today – has covered engines and engine-powered equipment. Through those nine decades, the writers and editors of this publication have witnessed technology that was considered science fiction in the 1930s and they’ve praised (as proper non-biased journalists) the entrepreneurs and engineers that have facilitated those changes. It’s been – and continues to be — an amazing thing to watch. Throughout 2025, we will be celebrating those 90 years. With this department, we’re going back to some of the unique applications, forgotten firms and the companies that have been part of the industry and the publication from the beginning of both.

Diesel engines and silk

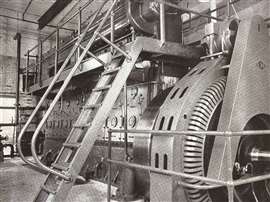

The front cover illustration of [the July 1940 issue] features one of New England’s most recent and largest industrial diesels. Situated at the Brighton, Mass., plant of the New England Spun Silk Corp., it represents a particularly interesting application of this modern power source to one of the world’s most ancient crafts. The outstanding economy and dependability of diesel-generated power have resulted in its use in practically every kind of manufacturing, but this unit adds a new chapter to the fascinating and profitable story of diesels by serving an industry that originated in China over 1,000 years ago, when Empress Si-Ling-Chi first domesticated silkworms and discovered the secret of unwinding their cocoons. Although, in the mind of the average person, there can be little, if any, connection between dainty silk fibers and this massive 1,000-hp diesel engine, the desirability of such a combination became increasingly obvious to the executives of this company as the solution to the problem of reducing operating costs. [A] savings of 50% or more of previous purchased power expense are indicated from their survey and actual engine operation since March 1 of this year, according to Chief Engineer Albert Goodhauser.

The generating unit selected is an eight-cylinder Price-Rathbun Oil Engine rated at 1,025 hp at 277 rpm, built by the Rathbun-Jones Engineering Corp. It is directly connected to a 700-kw Electric Machinery Manufacturing Co. alternator with the exciter mounted on top of it and V-belt driven from the main shaft, which ends in an outboard bearing. Due to the greater economy of installing a single unit compared with smaller, multiple engines and the further considerations of an extremely safe load factor and dependable performance records of this slow speed, heavy-duty diesel, it was decided to concentrate all generating capacity with no provision for standby or emergency power.

The engine has ample capacity for all power demands and during most of the operating periods is not required to carry full rated load, leaving plenty of reserve. A 15-kw utility service is retained for lighting during night periods and weekends when the engine is idle.

It may be of interest as [an] indication of the benefits to our economy of diesel-generated power to examine briefly the facts behind so basic and important an industry. When one considers that approximately 25% percent of raw silk fiber unreeled from a cocoon is waste unless processed in a plant of this type, the true importance of low costs in such production becomes apparent. In connection with national defense, which is now to the fore, spun silk is used extensively in the form of cartridge bag cloth (for firing large caliber guns) and finds a ready market in the manufacture of parachutes. By means of spinning short fibers it is possible to utilize silk from pierced, incomplete and weak cocoons and waste from reeling and weaving processes....

As the diesel enters yet another field of our industrial life it increases still further our productivity and national wealth through conservation of fuel, added efficiency and independence of power source.

When Dwight Robison wrote this article about a New England silk specialist for Diesel Progress, there were only five silk spinners in the United States. He reported that the country made “one-fifth of the world’s supply of spun silk” at that time.

When Dwight Robison wrote this article about a New England silk specialist for Diesel Progress, there were only five silk spinners in the United States. He reported that the country made “one-fifth of the world’s supply of spun silk” at that time.

This article originally appeared in the July 2025 issue of Power Progress.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM