Honda fuel cell power station backs up data center

06 March 2023

In a first step toward future commercialization, Honda has begun using a stationary fuel cell power station on the American Honda Motor Co., Inc. corporate campus in Torrance, Calif., to provide emergency backup power to an on-site data center. Fully operational as a demonstration project, the initiative leverages Honda’s hydrogen fuel cell technology will serve as a proof of concept for future commercialization of the power generation unit.

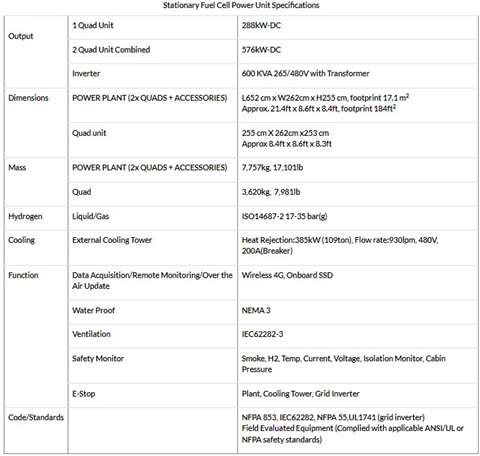

The demonstration unit has a capacity of approximately 500 kW and reuses the fuel cell systems of previously leased Honda Clarity fuel cell vehicles. Its design allows output to increase every 250 kW packaged with four fuel cells, Honda said. It offers the flexibility to change the layout of the fuel cell units to suit the installation environment and accommodate cubic, L-shaped, Z-shaped and other packaging configurations. Future versions intended for commercialization will utilize Honda’s next-generation fuel cell system jointly developed with General Motors, said Honda.

Koji Moriyama, project lead of the stationary fuel cell and principal engineer with American Honda R&D Business Unit, said the company sees great promise in hydrogen fuel cells for backup power and for offsetting potential peak power events. “By installing and utilizing our core technology, the fuel cell system, in various applications such as stationary power generation, Honda aims to stimulate hydrogen usage and provide clean energy for potential commercial customers,” he stated.

Honda also noted it plans to begin applying its next-generation stationary fuel cell systems in coming years to its manufacturing facilities and data centers globally as part of the company's global carbon neutrality goal for all products and corporate activities by 2050.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM