Kelvion Upgrades K°Bloc Heat Exchanger

27 March 2020

Kelvion said it has refined the K°Bloc fully-welded plate heat exchanger to further enhance its reliability and efficiency.

Designed and made in Germany, K°Bloc is designed to work across a broad range of liquids, temperatures and pressures and is suited to the demands of the oil and gas, chemical and petrochemical industries for separating mixtures of oil, water and solids.

K°Bloc is the result of decades of experience with demanding applications, more than 30 years of welded plate heat exchanger expertise and a commitment to continuous product improvement, the company said.

K°Bloc is available in various materials and different plate corrugations. The comb technology and the reinforced corner design make it suitable for high temperature and pressure process applications up to 50 barg and 400°C. High heat transfer rates allow compact K°Bloc designs, the company said. It also offers reduced total installation cost thanks to the higher recirculation rate and a lower static head.

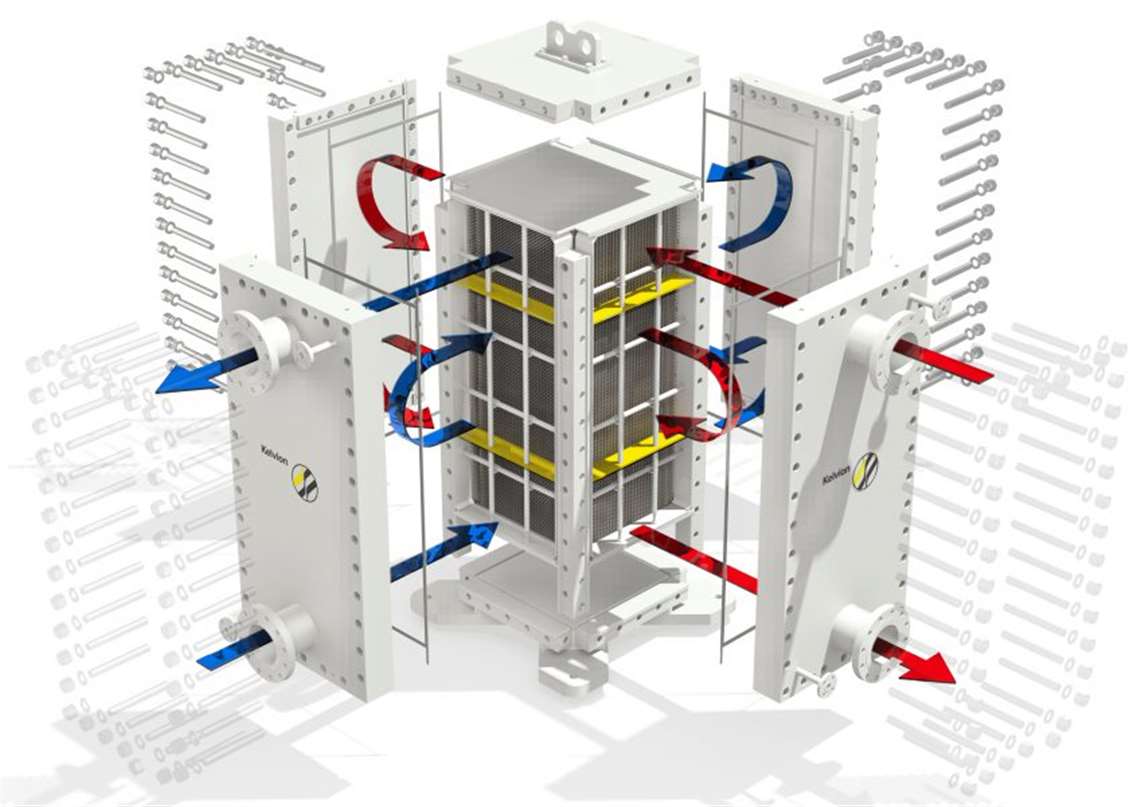

The K°Bloc frame consists of four columns, top and bottom heads and four side panels. These side panels can be detached to allow free access for cleaning the plate package.

The individual plates are welded alternately on the two longitudinal sides and at the corners. There are two pressure-resistant channels separated from one another inside the unit. The plate pack is installed between the four columns, four bolted panels and the top/bottom head plates, thereby forming a compact plate heat exchanger with two circuits. In the plate pack, the medium flows in a cross flow direction. The entire unit consists of a counter-current cross flow arrangement.

In addition, the heat transfer plates are corrugated to induce high turbulence and minimize fouling. The turbulent flow creates high shear stress on the walls, which literally scrubs deposits and fouling from the heat transfer surface. This is known as the ‘self-cleaning effect’. Consequently, the lowered fouling rate minimizes maintenance costs, extends service intervals and increases the heat exchanger’s availability.

Two different plate corrugations are available. Chevron corrugation enables effective heat transfer, while double dimple corrugation is the first choice for highly viscous or solid-containing media, as well as for vacuum applications.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM