Parker Hannifin introduces ToughShieldPlus part treatment

03 February 2022

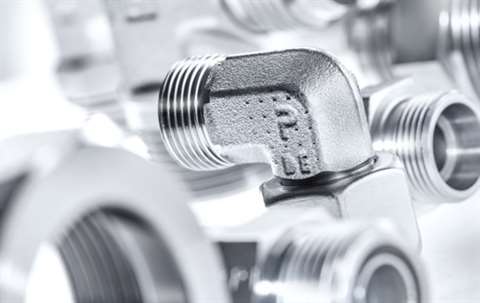

ToughShieldPlus coating from Parker Hannifin Photo credit: Parker Hannifin

ToughShieldPlus coating from Parker Hannifin Photo credit: Parker Hannifin

Motion and control technology specialist Parker Hannifin has introduced its new ToughShieldPlus zinc-nickel surface treatment for all tube fittings and adapters.

The plating provides increased resistance against corrosion, while maintaining part properties and ease of assembly.

The surface treatment has been under development for several years at the Parker Fluid Connectors Group in the US and Europe. This has helped determine the optimum surface treatment and related properties.

The basis of the new plating builds on the proprietary zinc-nickel alloy, passivated by a hexavalent chromium-free layer. The top coat is said to provide superior friction and assembly control.

Standard industry methods were used to test ToughShieldPlus, including Neutral Saltspray Testing and Cyclical Corrosion Testing.

This testing programme found that the ToughShieldPlus plating system can provide rust resistance for parts in fluid power systems for up to 3,000 hours.

Once it takes hold, rust can quickly spread across the part and to other components. This makes it important to prevent rust from starting by using the most resistant components.

ToughShieldPlus can prevent rust from starting, which helps to save time and money through extended tube fitting and adapter life and ease of maintenance. It can help improve equipment up time, prevent aesthetic discolouration and save on warranty costs.

The ToughShieldPlus system complies with industry standards, such as DIN and SAE, and also the RoHs, REACH and ELV environmental standards.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM