Systems & Components Trophy winners named

06 November 2025

DLG presents award as part of Agritechnica trade show

As part of November’s Agritechnica trade show, the event’s organizer, DLG, awards the Systems & Components Trophy - Engineers’ Choice for components and systems. DLG said the award recognises the importance and innovative strength of the agricultural machinery supply industry.

From a shortlist of 16 nominated innovations for the award, the winners were selected in a second round by a jury of development engineers from the agricultural machinery manufacturers exhibiting at Agritechnica in Hanover, Germany.

The award ceremony for the winners will take place on 9 November 2025 at the Systems & Components Expert Stage in Hall 17, H02.

The winners for 2025 are:

ZF Group

ZF eTD

Hall 15 | Stand C06

Drivetrain technologies

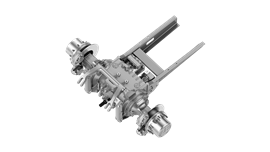

The ZF eTD. (Photo: DLG)

The ZF eTD. (Photo: DLG)

In current electric tractors, the combustion engine has generally been replaced by an electric motor with a reduction gear, without affecting the familiar and proven hydrostatic power-split CVT drivetrain.

The electric TerraDrive (eTD) from ZF Friedrichshafen takes a new approach: The modular, highly integrated electric axle system combines traction, PTO and hydraulics in a compact design for tractors up to 100 kW. This not only enables emission-free operation without any loss of power, but also means that central transmissions, hydrostatic units, clutches, and hydraulic systems can be partially eliminated or replaced by a dual electric powertrain with energy recovery and an optimized design for maximum efficiency and flexibility during installation. At the heart of the eTD is a highly integrated electric drive unit with two oil-cooled electric motors – one for the drive, the other for auxiliary drives. The change in the basic design concept creates space for batteries or hydrogen tanks, which can significantly increase range and operating time. The S&C Trophy commission said this not only applies to tractor applications, but can also be transferred to other machines.

The eTD represents a scalable, future-proof solution for emission-free agriculture without compromising on performance or functionality.

Mach Inc.

RadX

Hall 17 | Stand C05

Vehicle Electronics

The Mach RadX. (Photo: DLG)

The Mach RadX. (Photo: DLG)

As technology advances, more and more sensors are being used in agricultural machinery and tractors to improve their control. The raw data from these sensors usually is processed centrally, which places high demands on computing power and data analysis. OEMs repeatedly struggle with difficulties in evaluating sensor data and programming efficient evaluation algorithms.

Mach said its RadX radar device is the first system of its kind to bring true phased array technology to agriculture, construction, mining and land management, and process the captured signals internally and make them available in the OEM’s system architecture. The system uses electronically controlled beams and adaptive beamforming for high-resolution 3D detection in real time, eliminating the need for moving parts.

RadX can distinguish between soil, crop residues and vegetation while simultaneously mapping the terrain surface, making the sensor particularly interesting for use in depth control of tillage, planting, and seed drills as well as in terrain guidance for combine harvester headers. An evaluation of the quality of work behind the machine is also conceivable, said Mach.

Mach said the RadX system represents an important innovation for the future of 3D image-based environment detection and control of mobile machines in agriculture.

Igus GmbH

ReBeL Cobot

Hall 16 | Stand E11

Vehicle Electronics

The ReBeL from Igus. (Photo: DLG)

The ReBeL from Igus. (Photo: DLG)

High-precision and repetitive tasks such as weeding or harvesting of fruit are often physically demanding and are still frequently carried out manually, requiring a large workforce.

With the ReBeL Cobot, Igus has introduced an articulated arm robot weighing only 8 kg, which, thanks to its simple operation and low price, the company said makes entry into automation in agriculture easier and more accessible than ever before. Equipped with sensors and grippers, it is ideal for tasks such as fruit harvesting, sowing or indoor farming. Depending on the application, the robot arm can be equipped with various sensors such as cameras or work tools. In addition, it offers simple, user-friendly, and practical programming options. Using a free, license-free software test environment, users can test any kinematics and thus find out before purchasing whether the planned application can be realized with the ReBeL.

Mounted on a suitable autonomous chassis, the igus ReBeL Cobot can, for example, reduce the use of labor during harvesting and at the same time enable a higher number of harvest passes, which leads to greater efficiency and less strain on harvesting personnel.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM