Battery Testing Capabilities In The U.K. Expanded

22 October 2020

Responding to what it said was soaring demand from in the U.K. for advanced battery safety testing, Horiba Mira, part of the global Horiba Group, said it has invested £1.5 million (US$1.9 million) in a new Large Climatic Vibration Laboratory and Battery Abuse Facility in Warwickshire in the U.K.

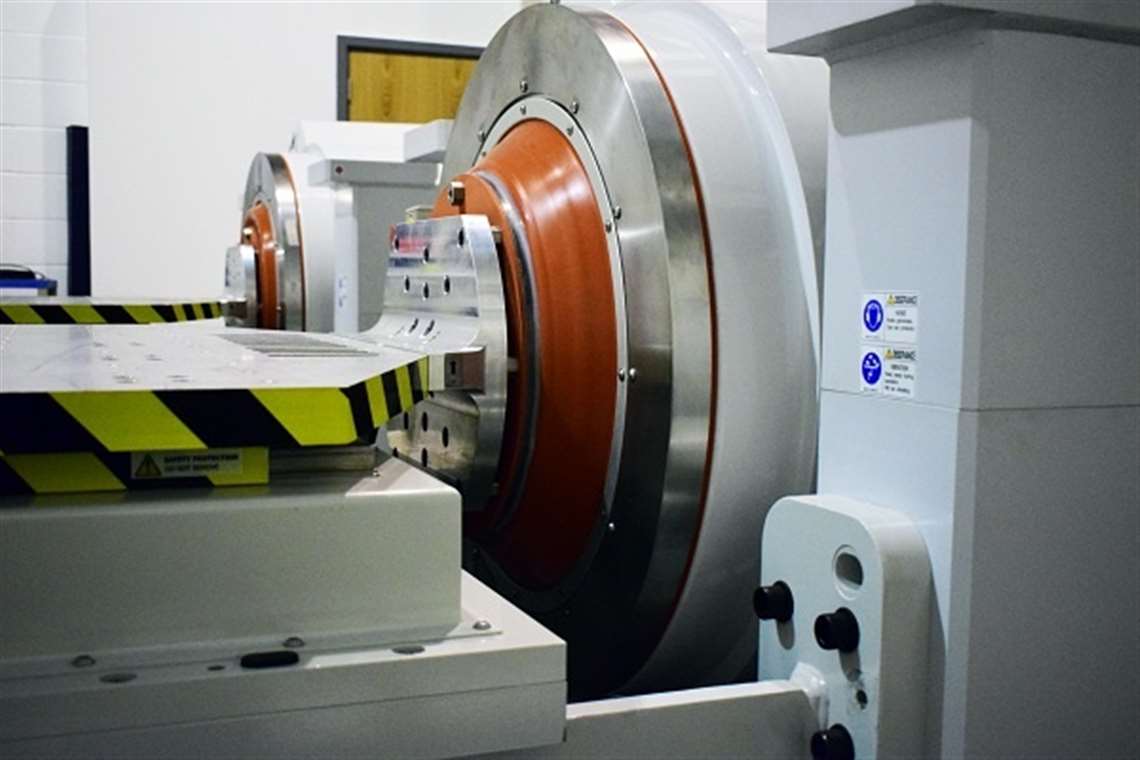

Set to open this month, Horiba Mira said the new Large Climatic Vibration Laboratory is the U.K.’s first battery vibration test facility to also offer electrical and thermal cycling. It enables battery charging and discharging whilst in use, along with climatic capability, to carry out tests in ambient conditions ranging from -40°C to 100°C (-40° to 212°F).

The new twin vibration facility can operate in three axes and has the capacity to vibrate up to one tonne of mass, making it suitable for testing the biggest EV batteries on the market to regulatory standards such as UN38.3 and ECEReg100, the company said.

“The environmental and societal drive towards zero emissions transport has increased the need for more advanced battery engineering and the testing capability to support that,” said Eamonn Martin, solution manager for Electrification and Environmental Validation at Horiba Mira. “At Horiba Mira, we’ve been developing batteries and testing them for our customers for almost 20 years. This latest investment complements our existing EV battery development portfolio with additional capability to validate the latest battery technologies.”

The shaker is the second part of the recent investment into battery safety related testing, which includes its new Battery Abuse Test Facility (BAT) that opened in July. The BAT facility provides abuse and safety testing at cell, module and pack level, in all-weather conditions, supported by high speed cameras, thermal imaging and gas detection.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM