Cummins on show at Agritechnica

24 October 2019

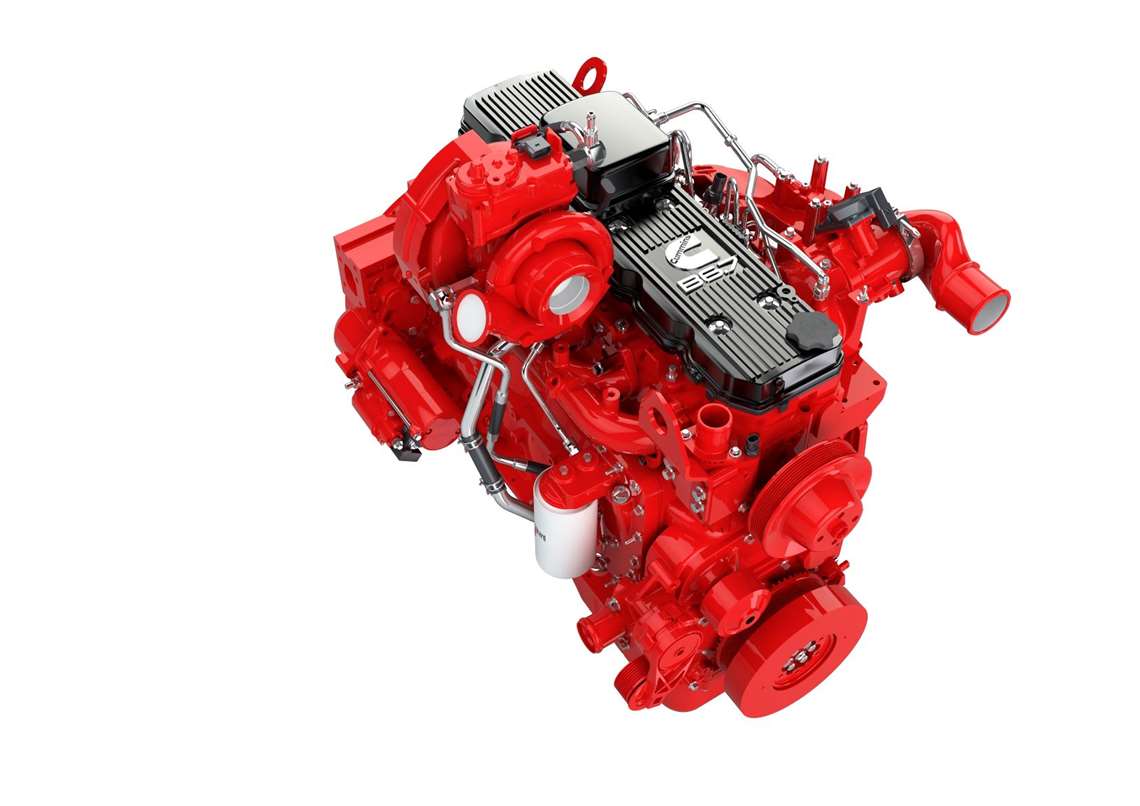

Cummins said its Stage 5 B6.7 Performance Series engine will be available in Claas AVERO combine harvesters from quarter four 2019. Cummins will display its Performance Series at Agritechnica, alongside the structural B6.7 engine for agricultural tractor applications.

The Darlington, England-built engine has been integrated with Claas’s powertrain for the AVERO. Delivering 157 kW maximum power and 990 Nm peak torque in Claas’s larger model and 123 kW, 746 Nm peak torque in the smaller model, the B6.7’s power and torque curves have been tailored specifically to AVERO’s duty cycle using Cummins’ in-house electronic controls, fuel injection, air handling and exhaust aftertreatment technologies, said Cummins.

Cummins said that while many manufacturers “have adopted a ‘same as’ strategy from Stage 4 to Stage 5”, Cummins technology means its Stage 5 products deliver more power and less complexity through the removal of exhaust gas recirculation (EGR) on engines up to 12 L displacement, the company claimed.

Stage 5 emissions requirements are met through Cummins’ Single Module aftertreatment system which combines a diesel oxidation catalyst (DOC), a diesel particulate filter (DPF) and selective catalytic reduction (SCR) in a single unit. The system is 40% smaller and 20% lighter than Cummins’ Stage 4 solution and features a compact AdBlue/Diesel Exhaust Fluid mixer which removes the need for a decomposition reactor tube, making the whole system easier to keep clean, the company said.

Cummins added that its decision to remove EGR at Stage 5 offers benefits for Claas global operations, as well as for its farming customers. Without EGR, the same Cummins engine platform can be applicable for sales to multiple emissions standards, from Stage 5 and Tier 4 final, down to unregulated levels, it said.

Ann Schmelzer, general manager Global Agriculture, at Cummins said: “During the integration process, we worked closely with Claas to understand the requirements of both their machine and their customers – the farmers who operate AVERO. As such, the B6.7 engine delivers the high-power density, machine capability and efficiency required from a combine harvester, while its simpler architecture with fewer parts means higher reliability, easier accessibility, less maintenance and more productivity for farmers.”

The photo shows a Cummins B6.7 Performance Series engine.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM